Screenshot of some of the data and both charts

Import

Select to delete

Export

Import

Select to delete

Export

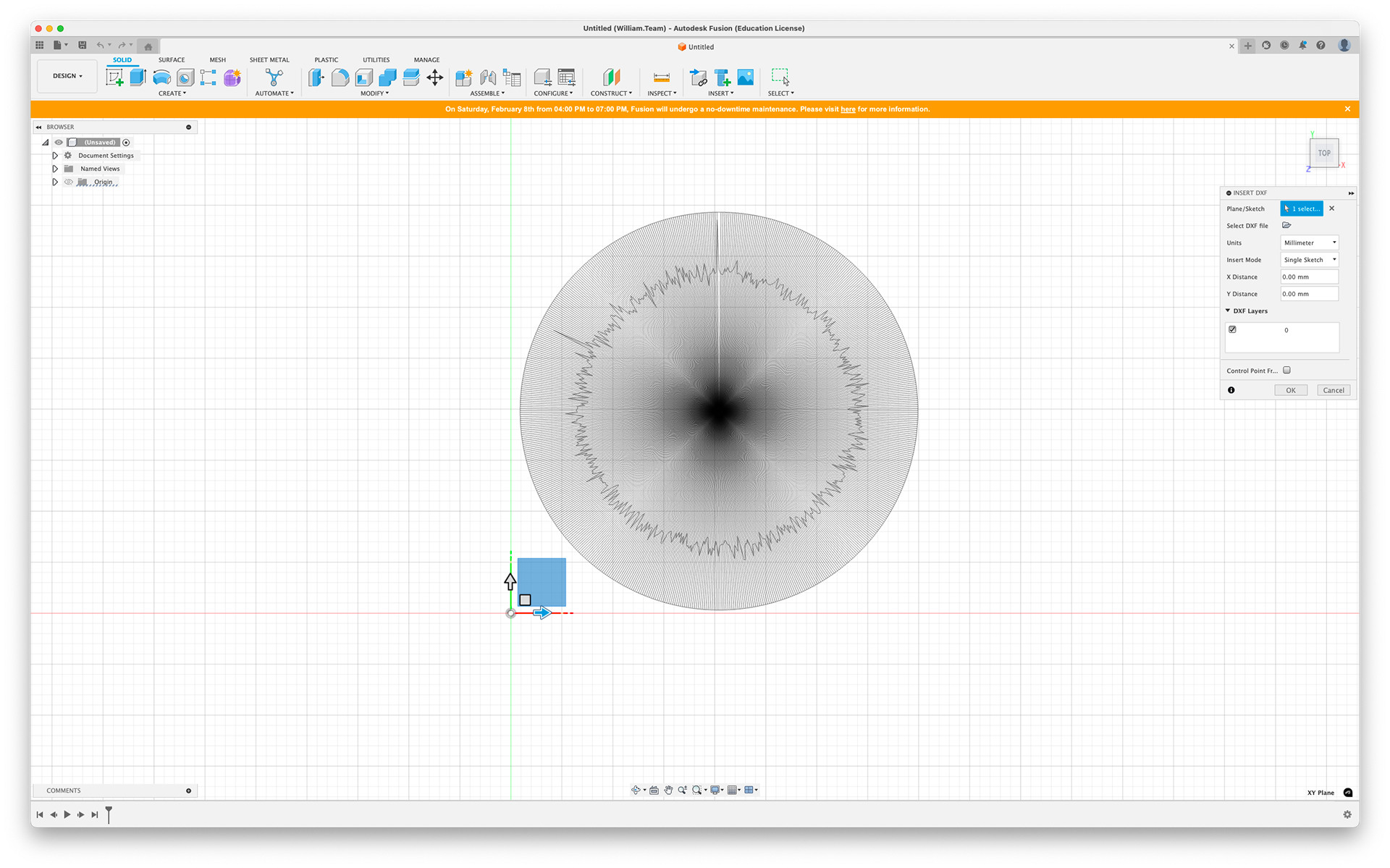

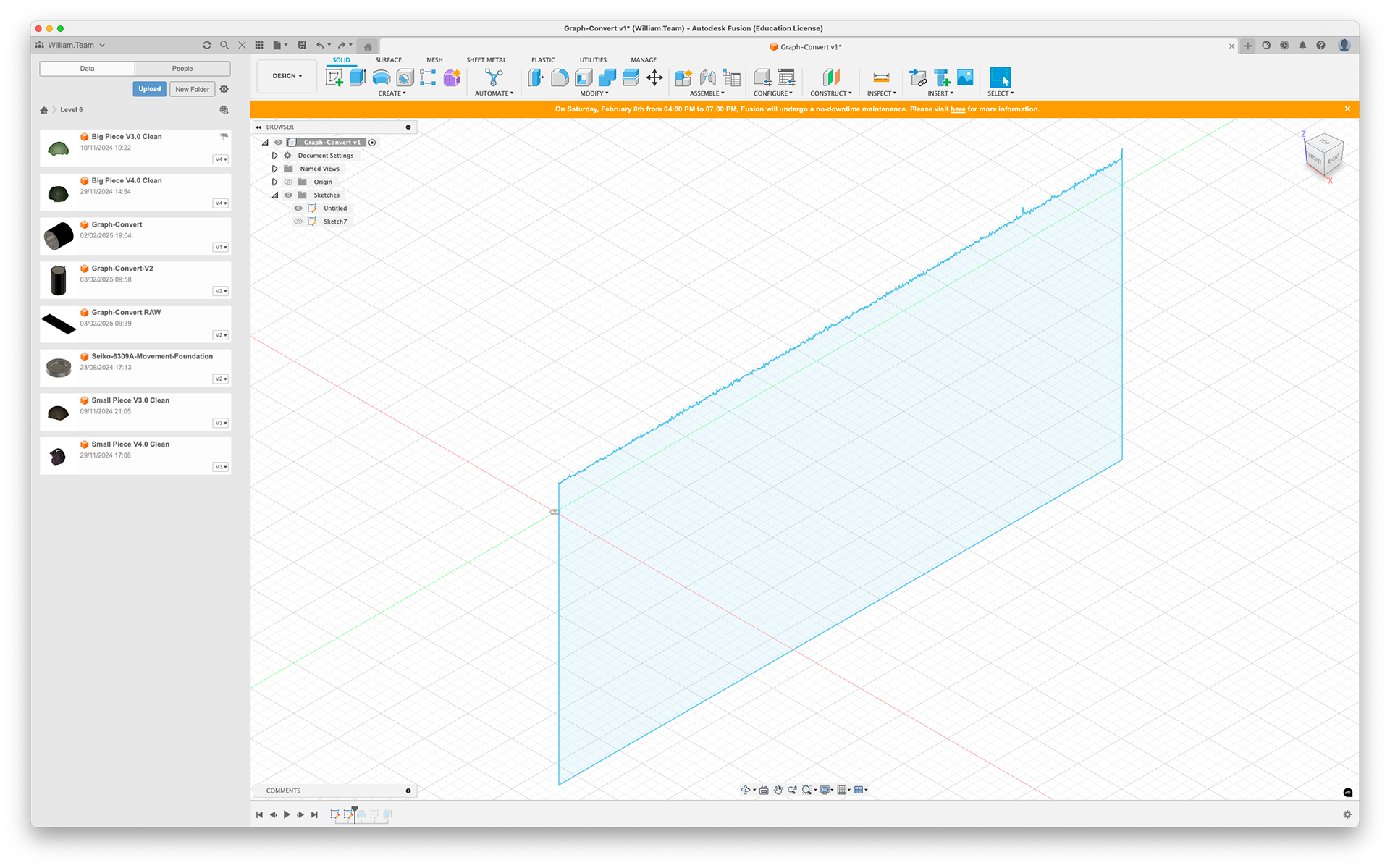

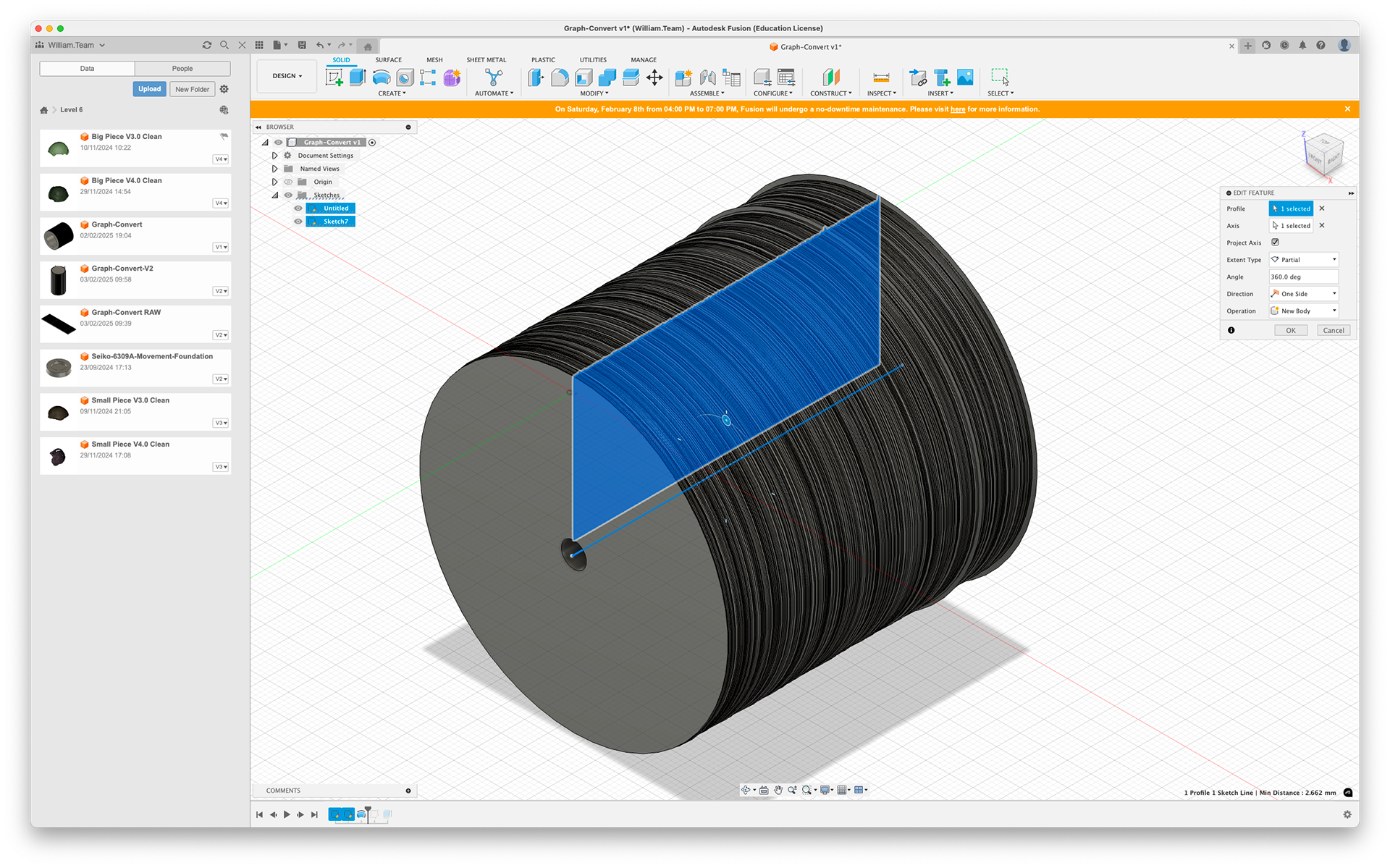

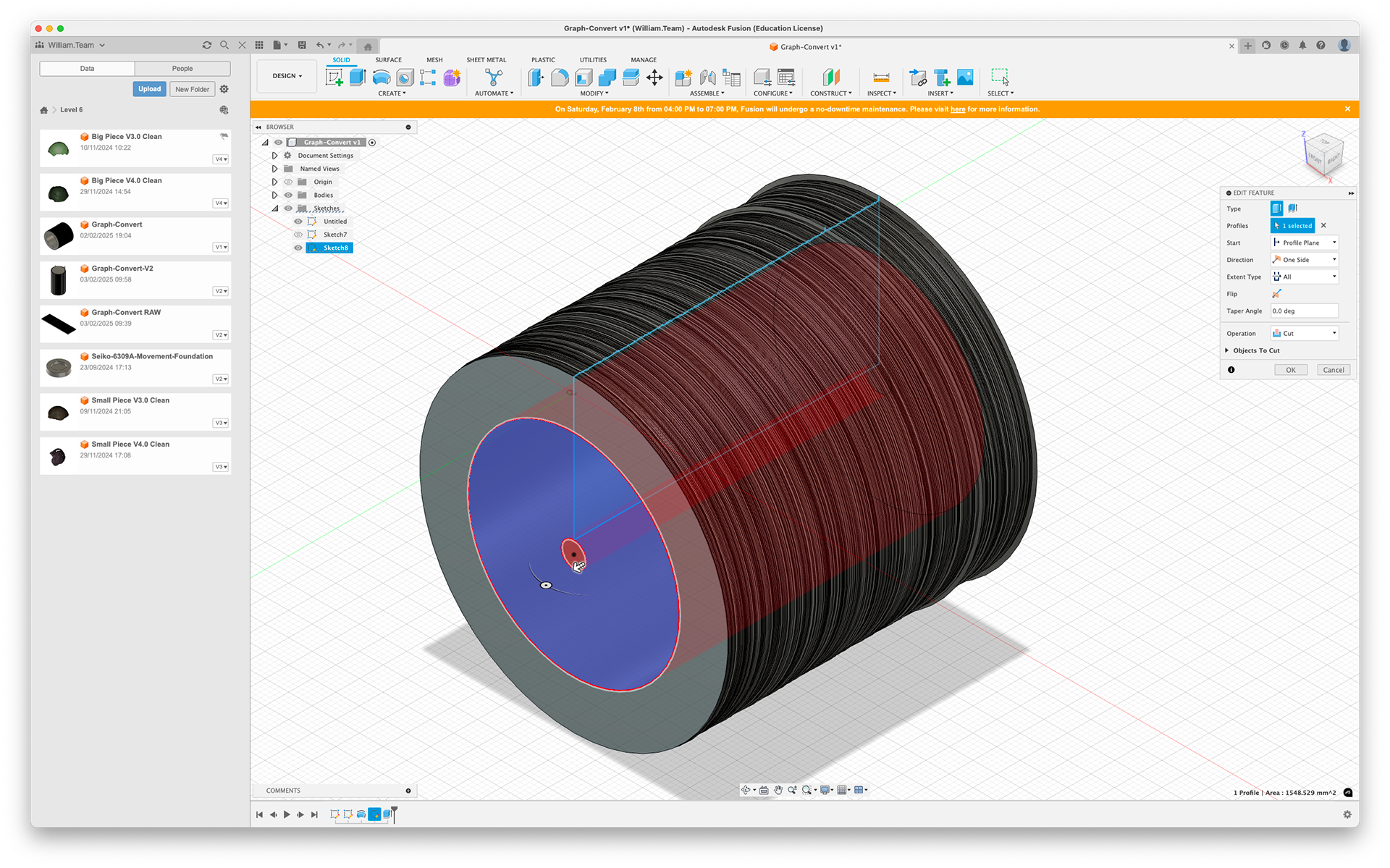

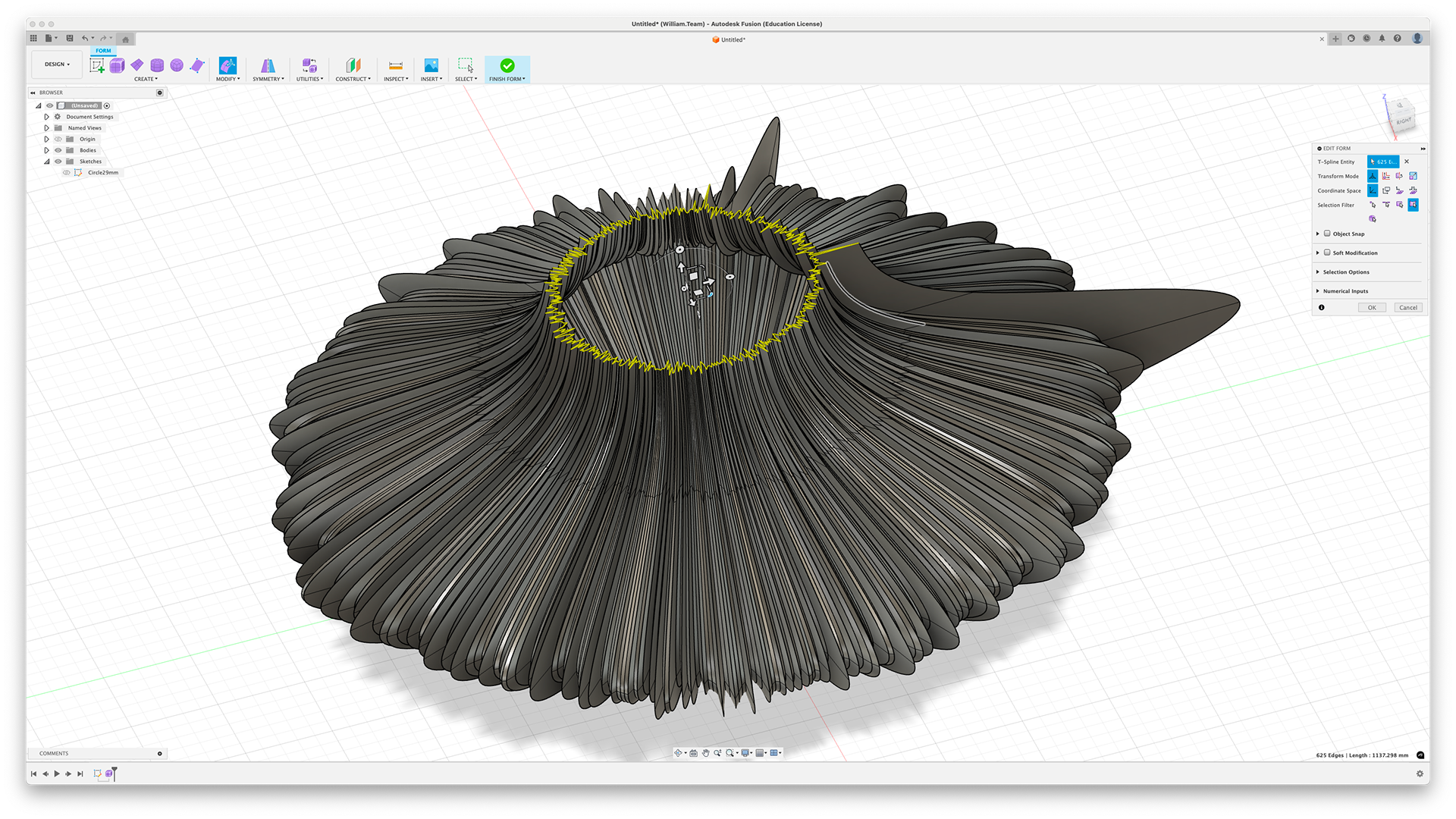

Line Chart Revolve

Line Chart Revolve

Line Chart Revolve

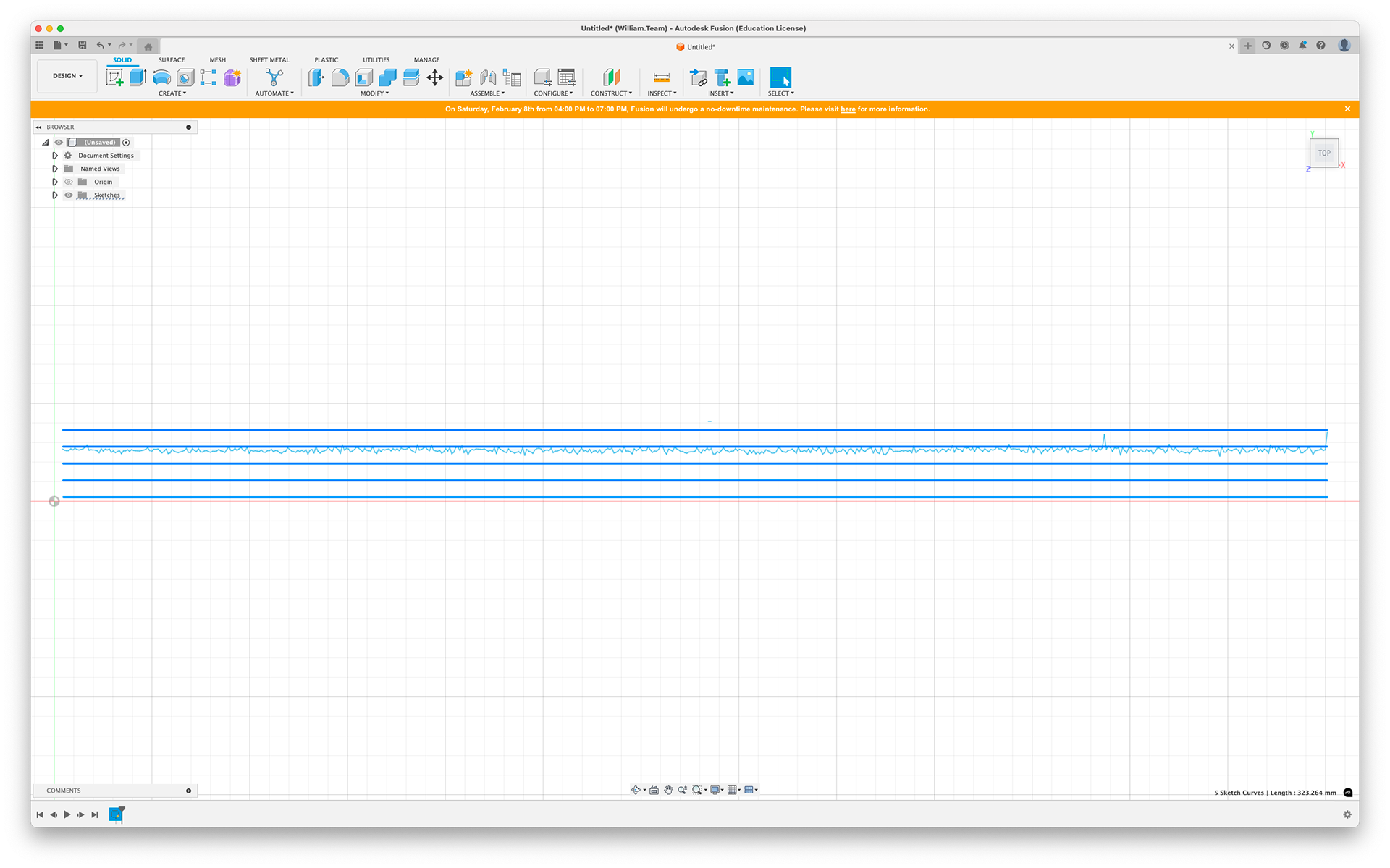

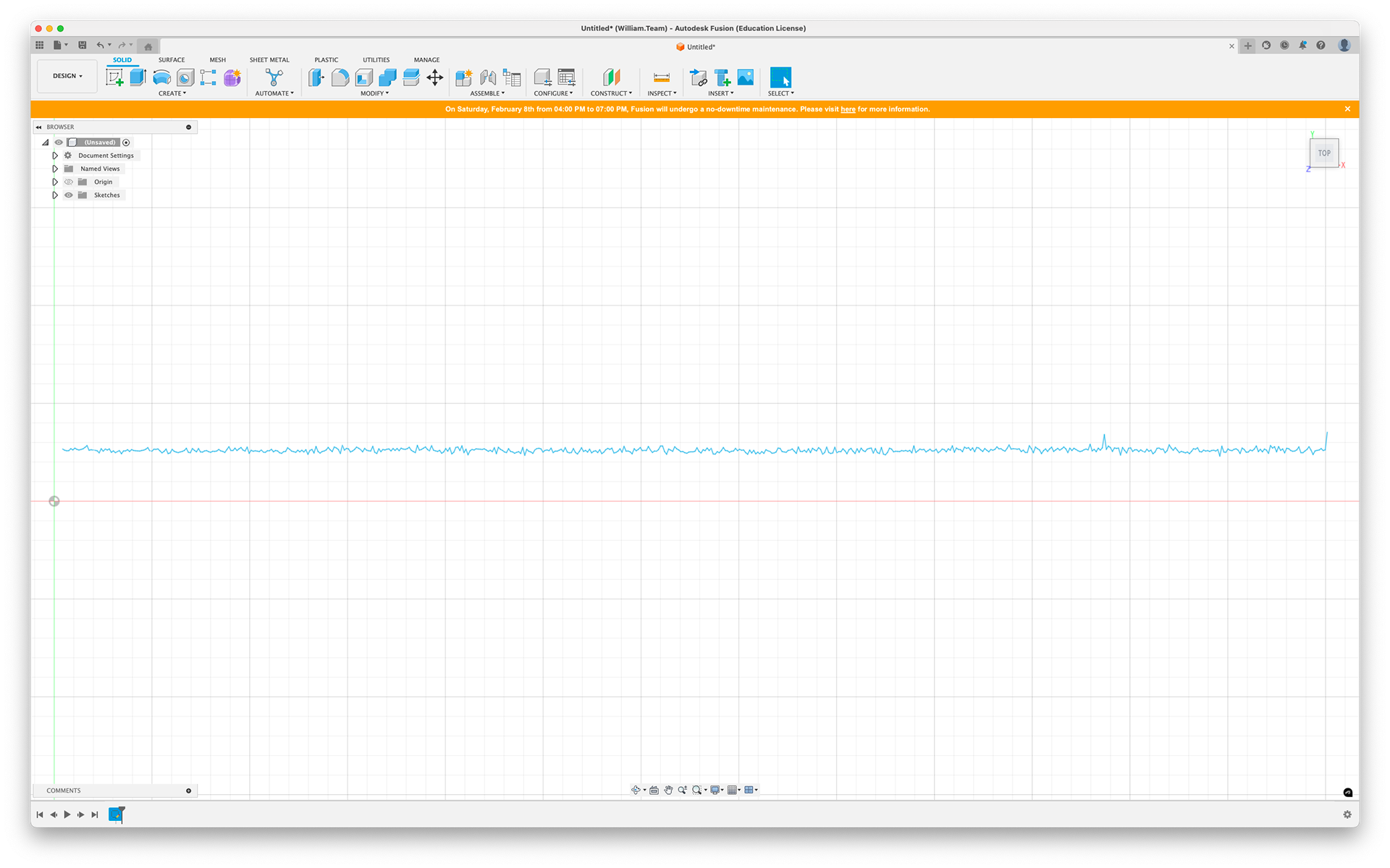

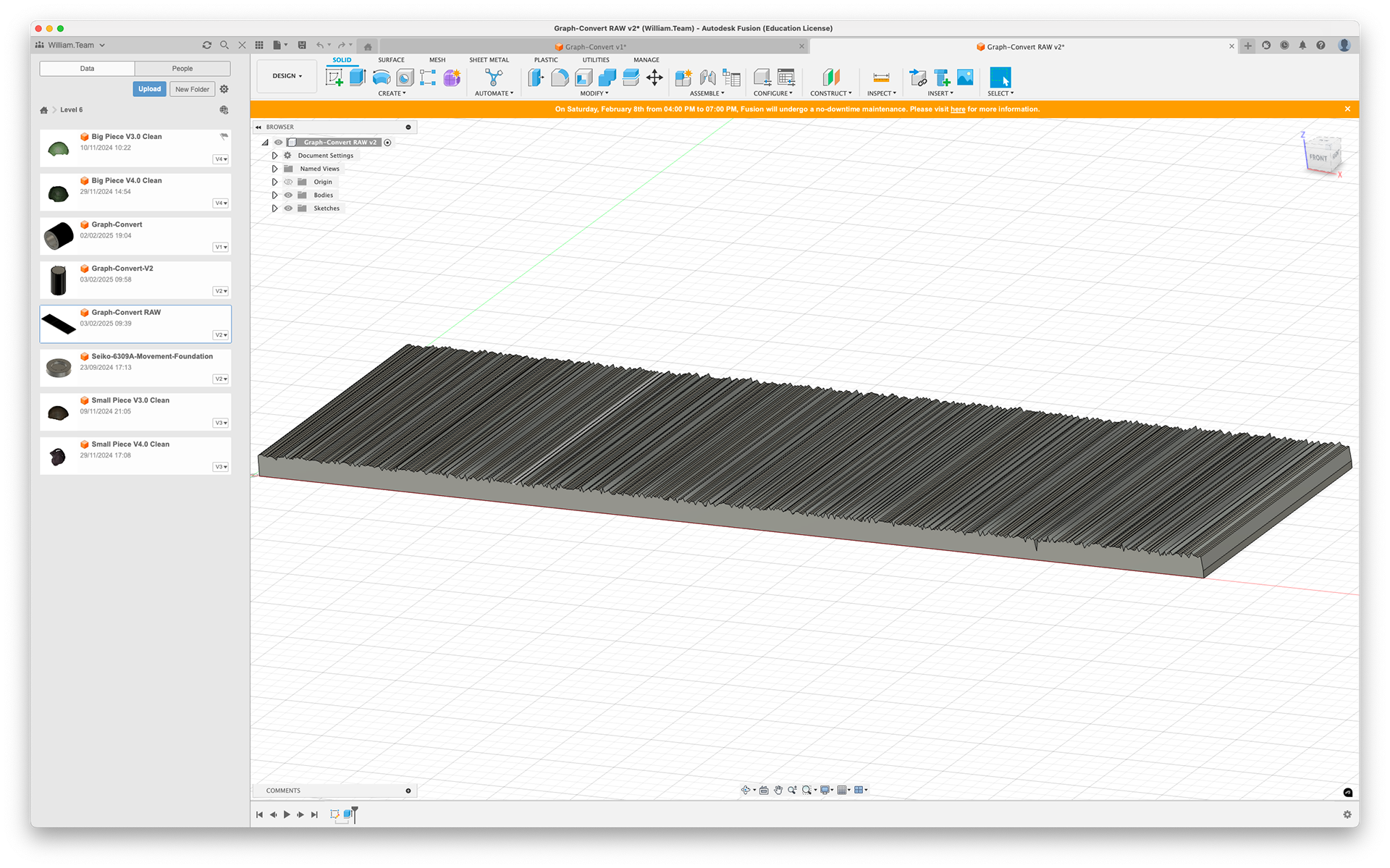

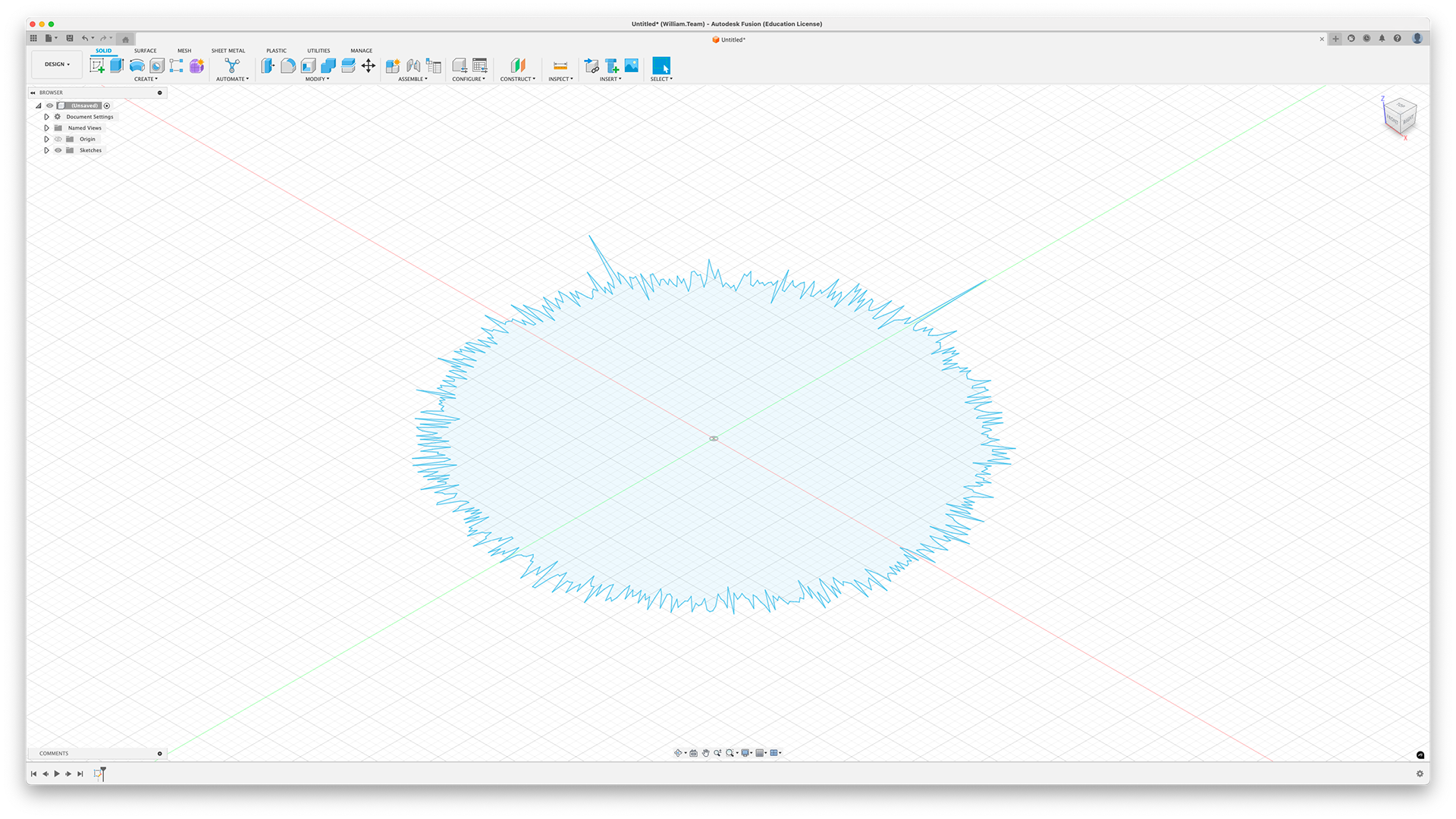

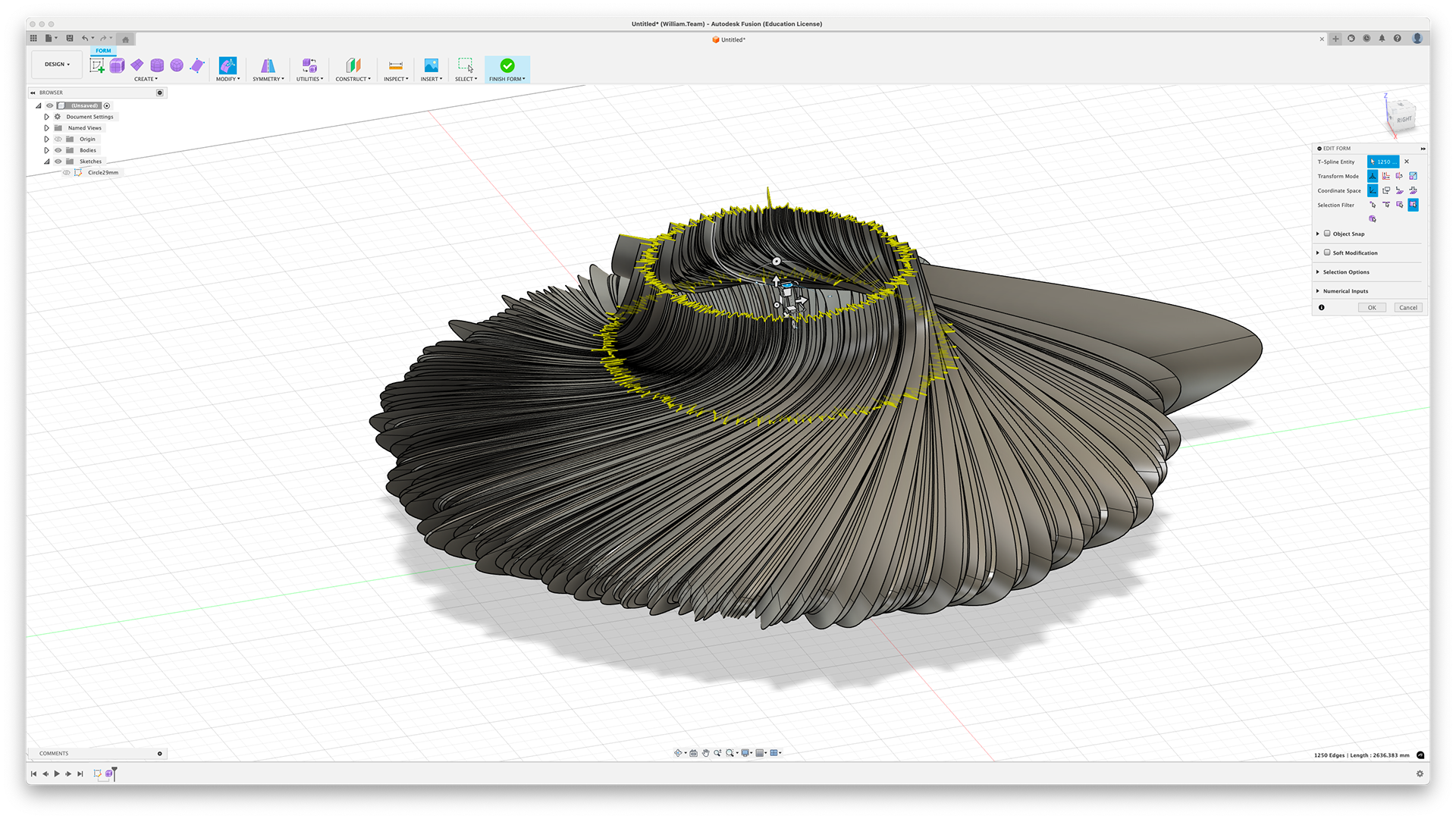

Line Chart Plane

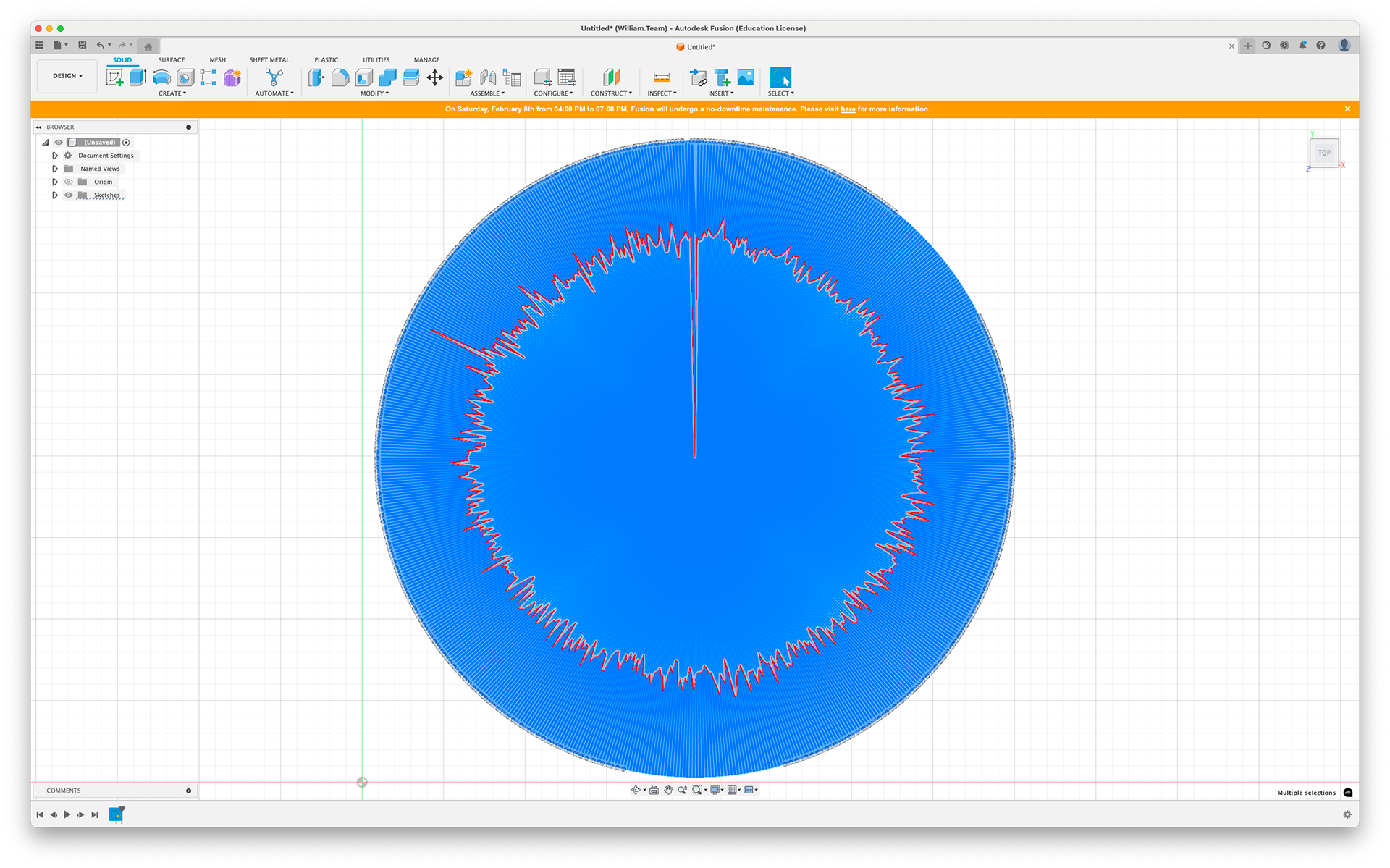

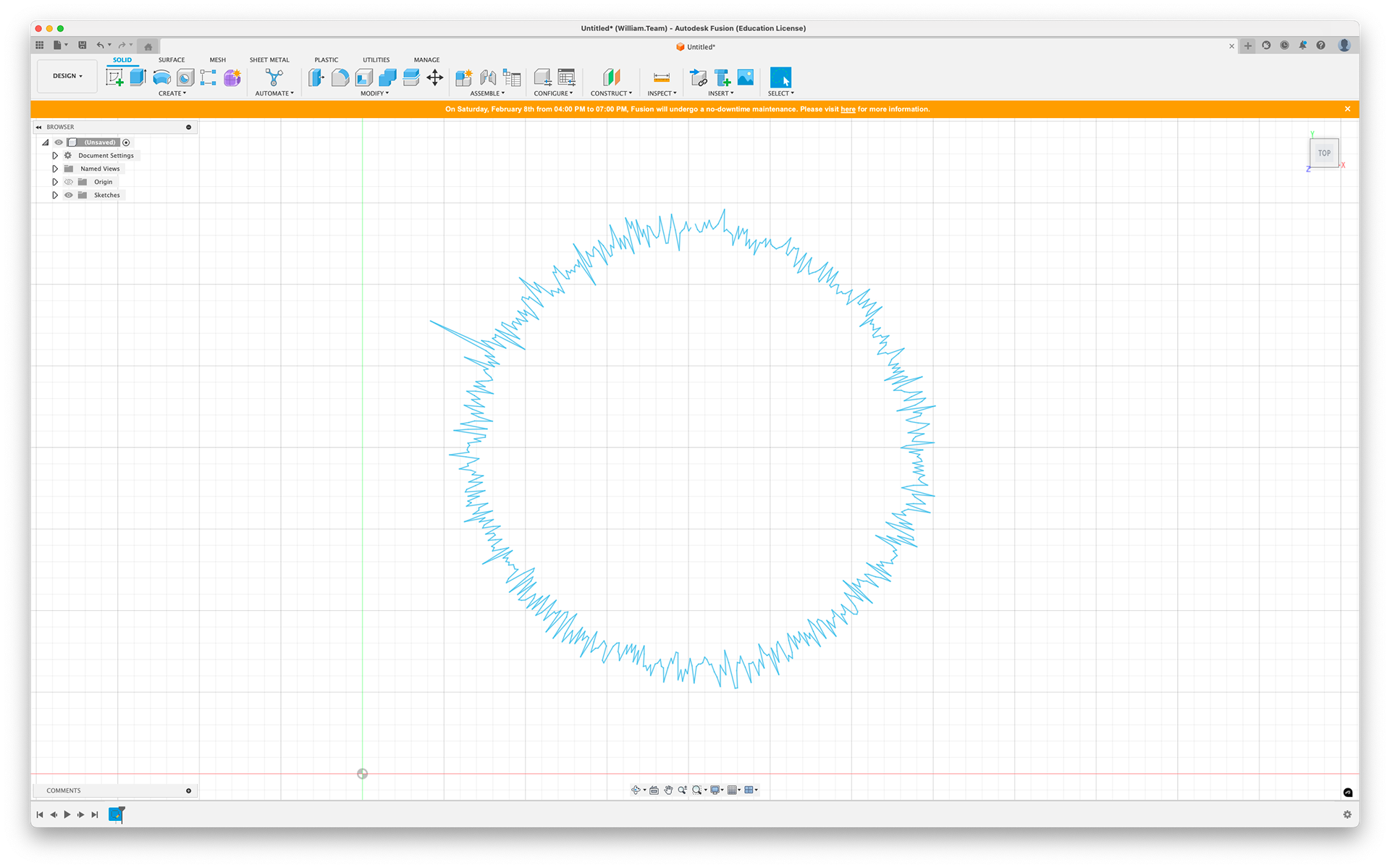

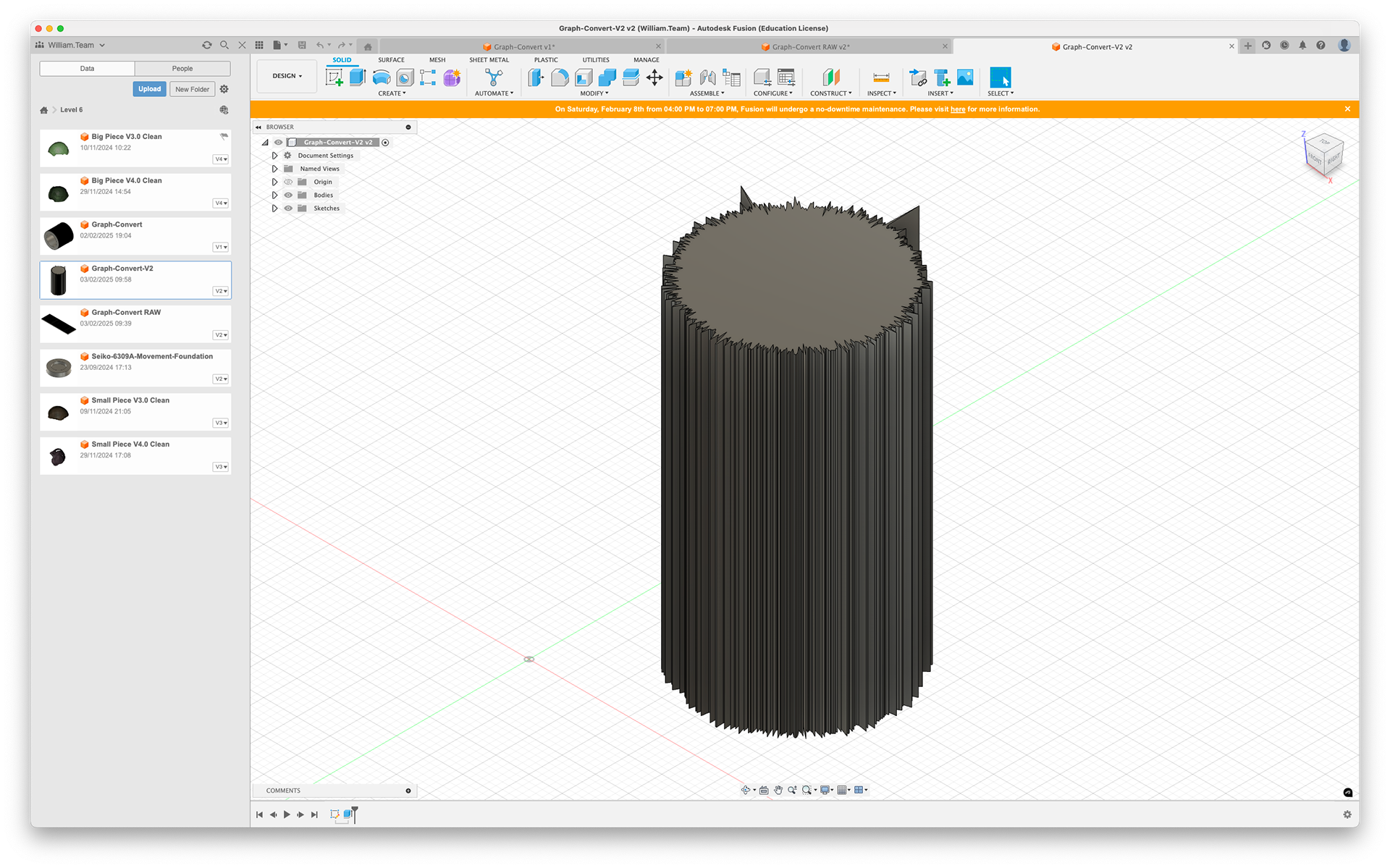

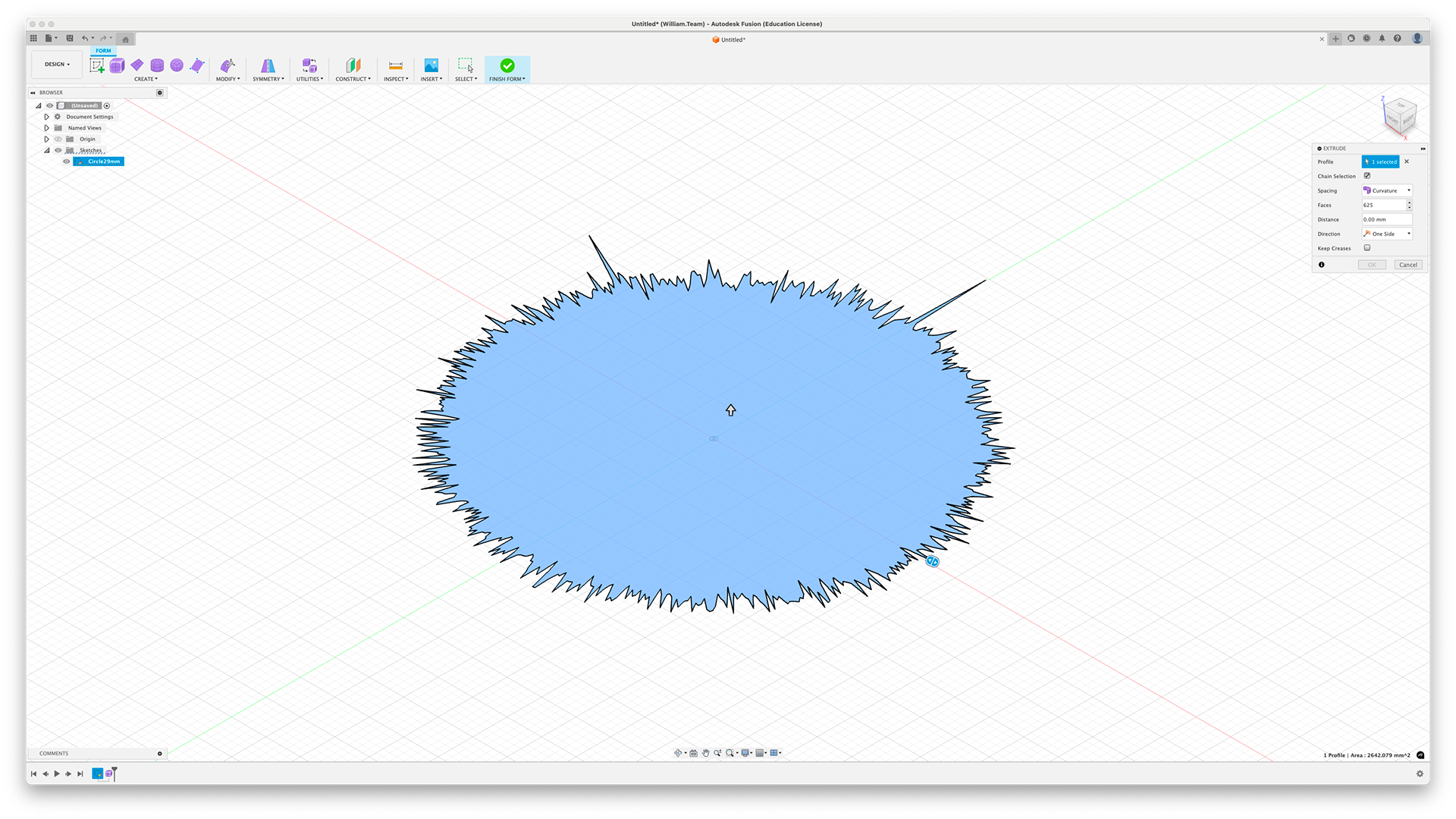

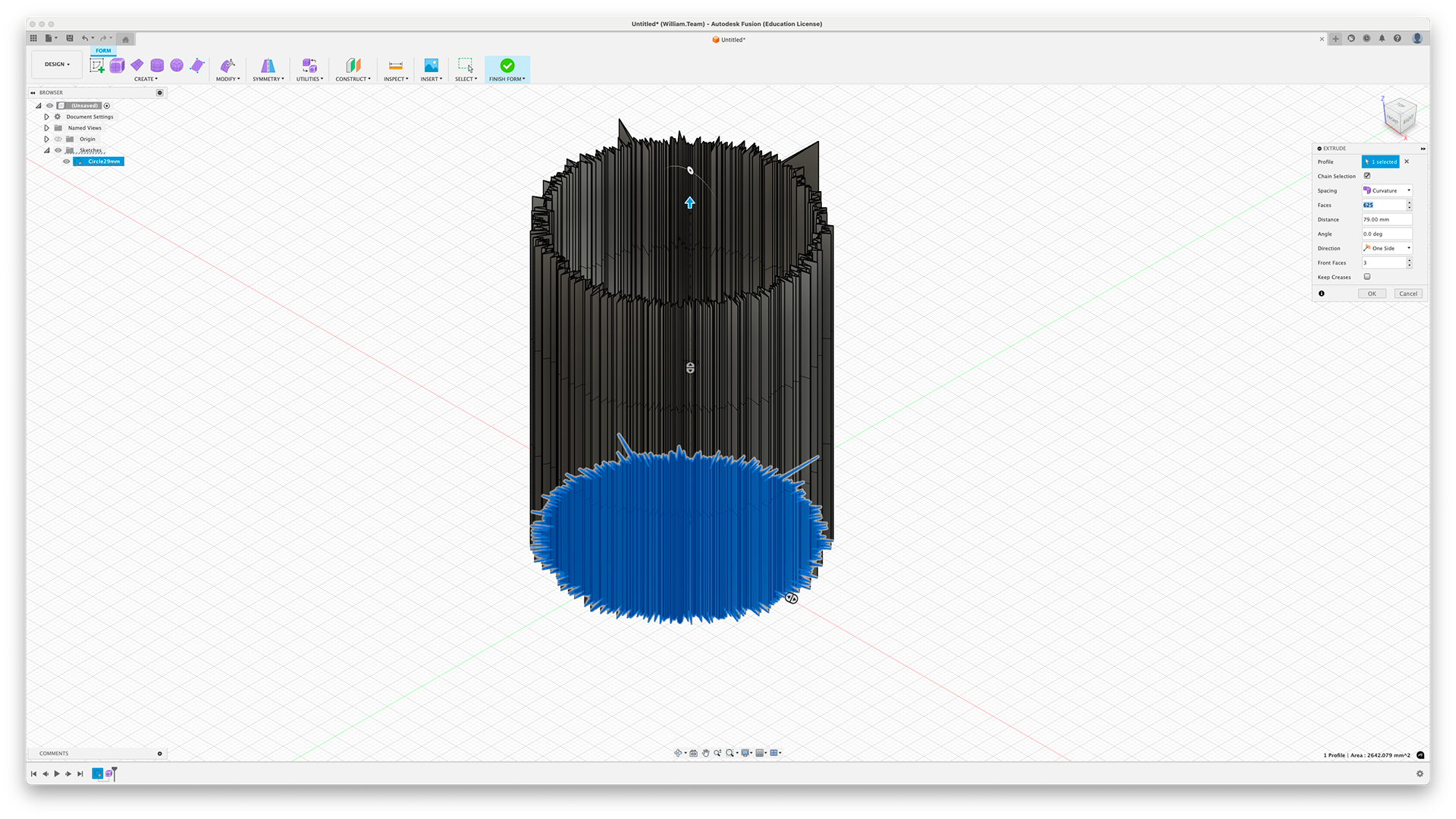

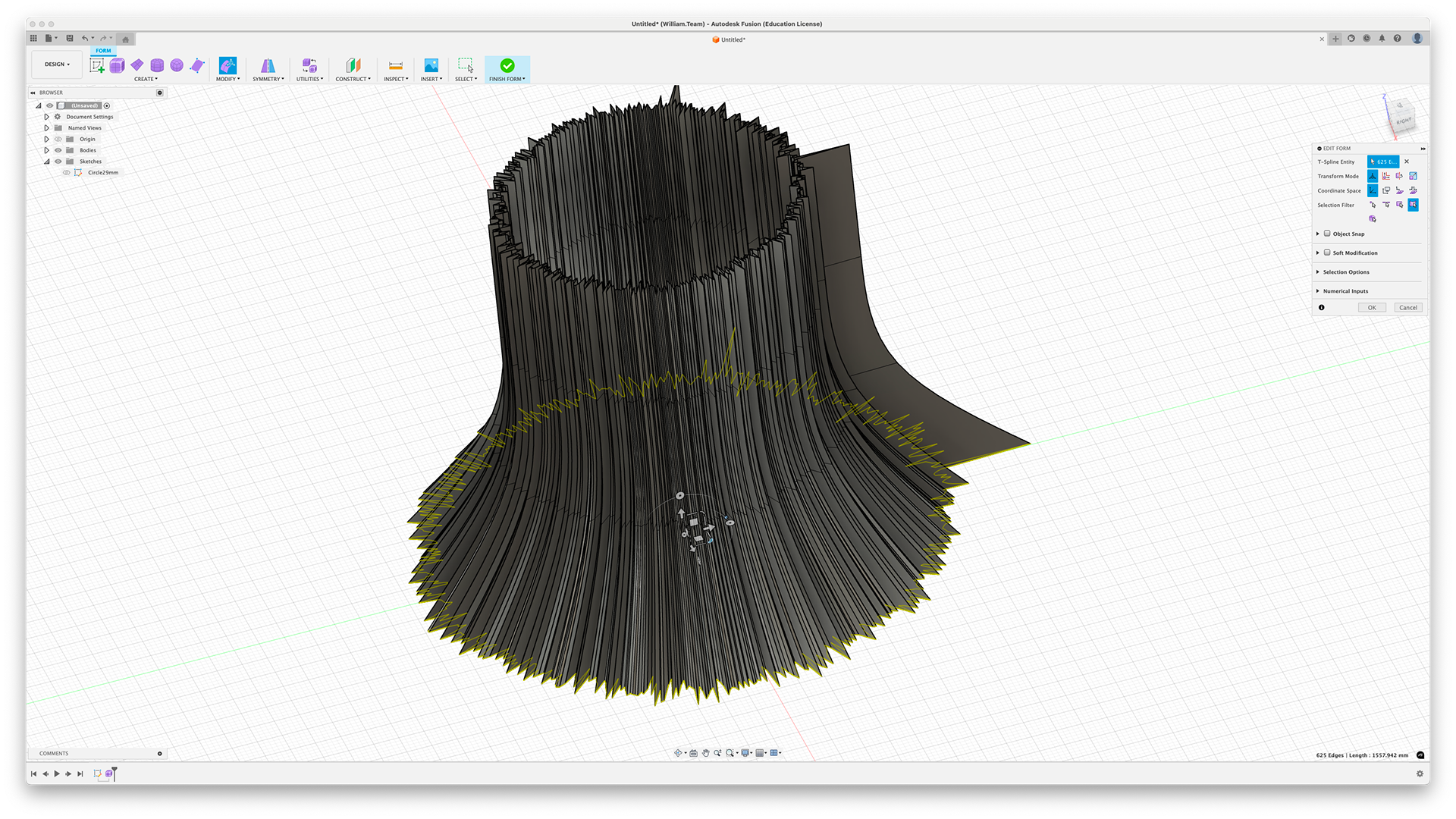

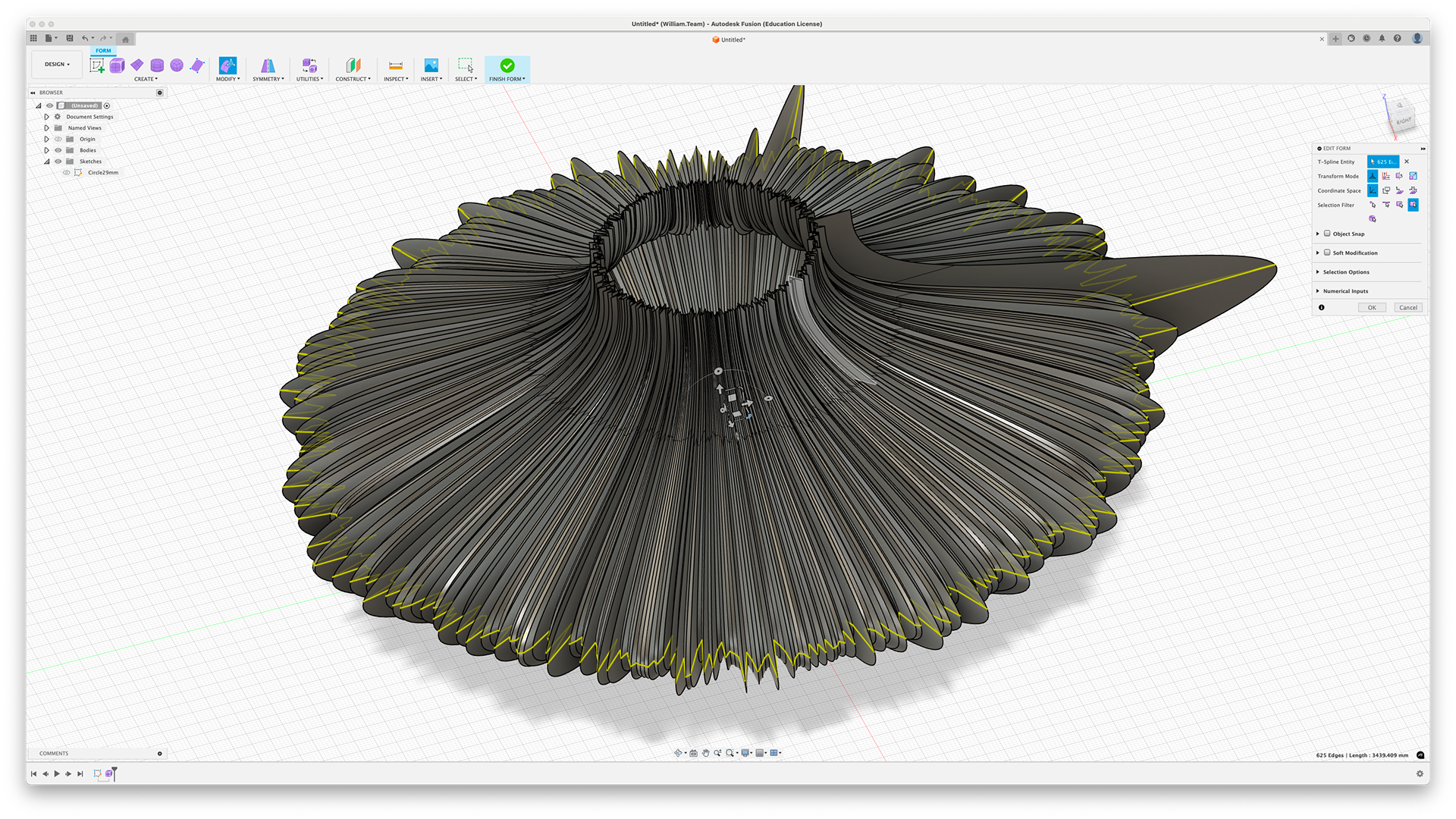

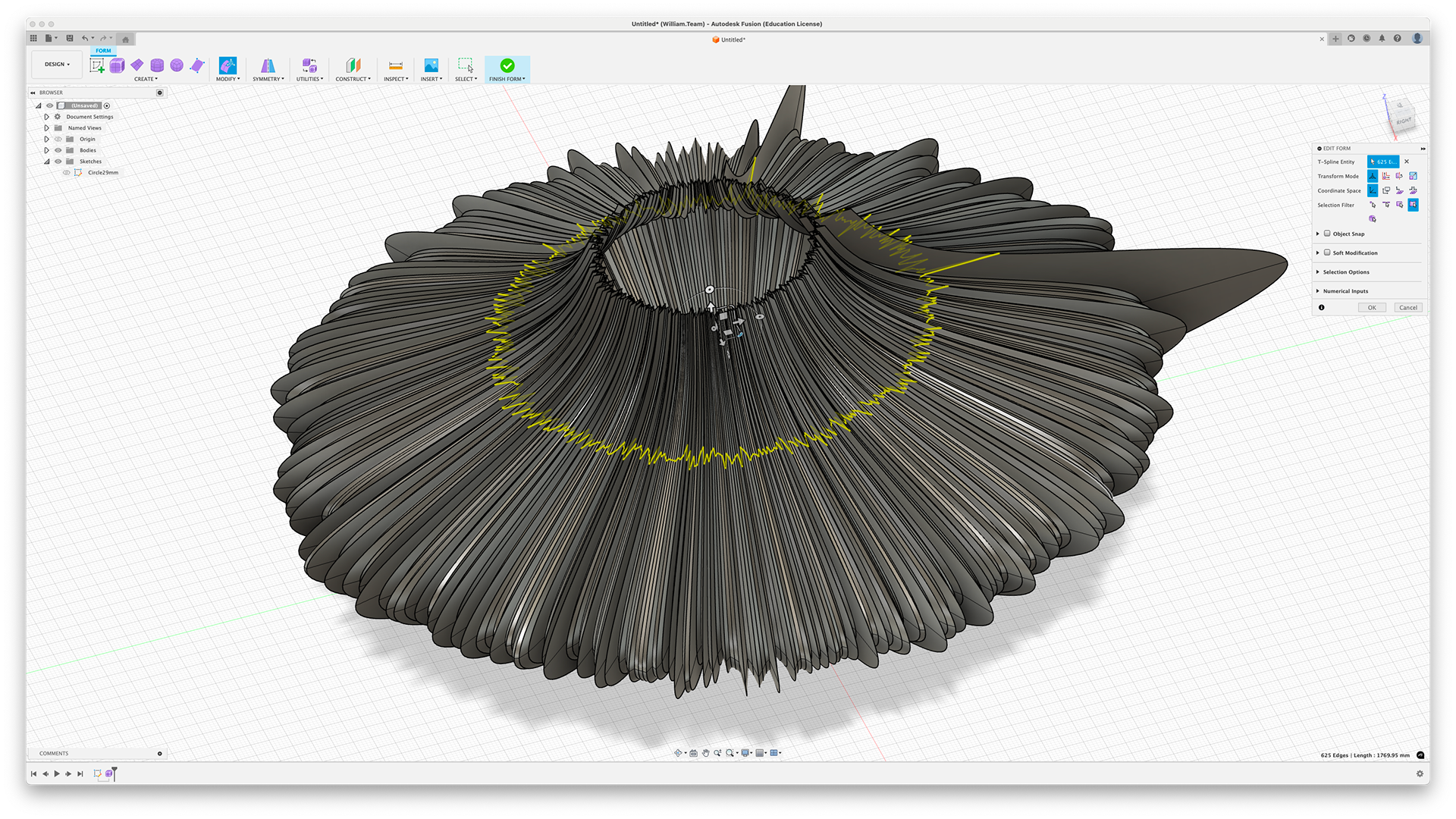

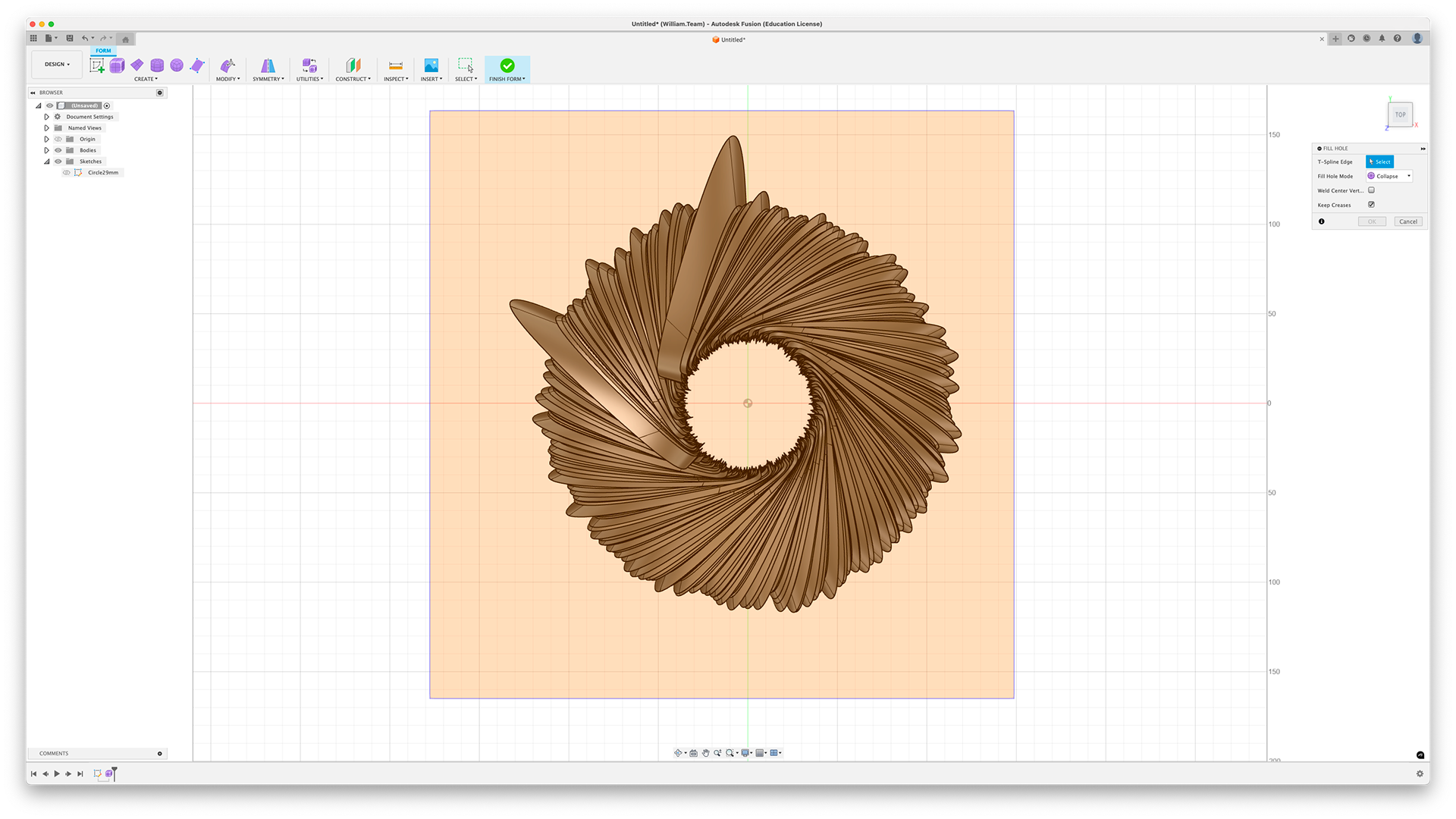

Radar Chart Extrude

Screenshot of a portion of the sleep data.

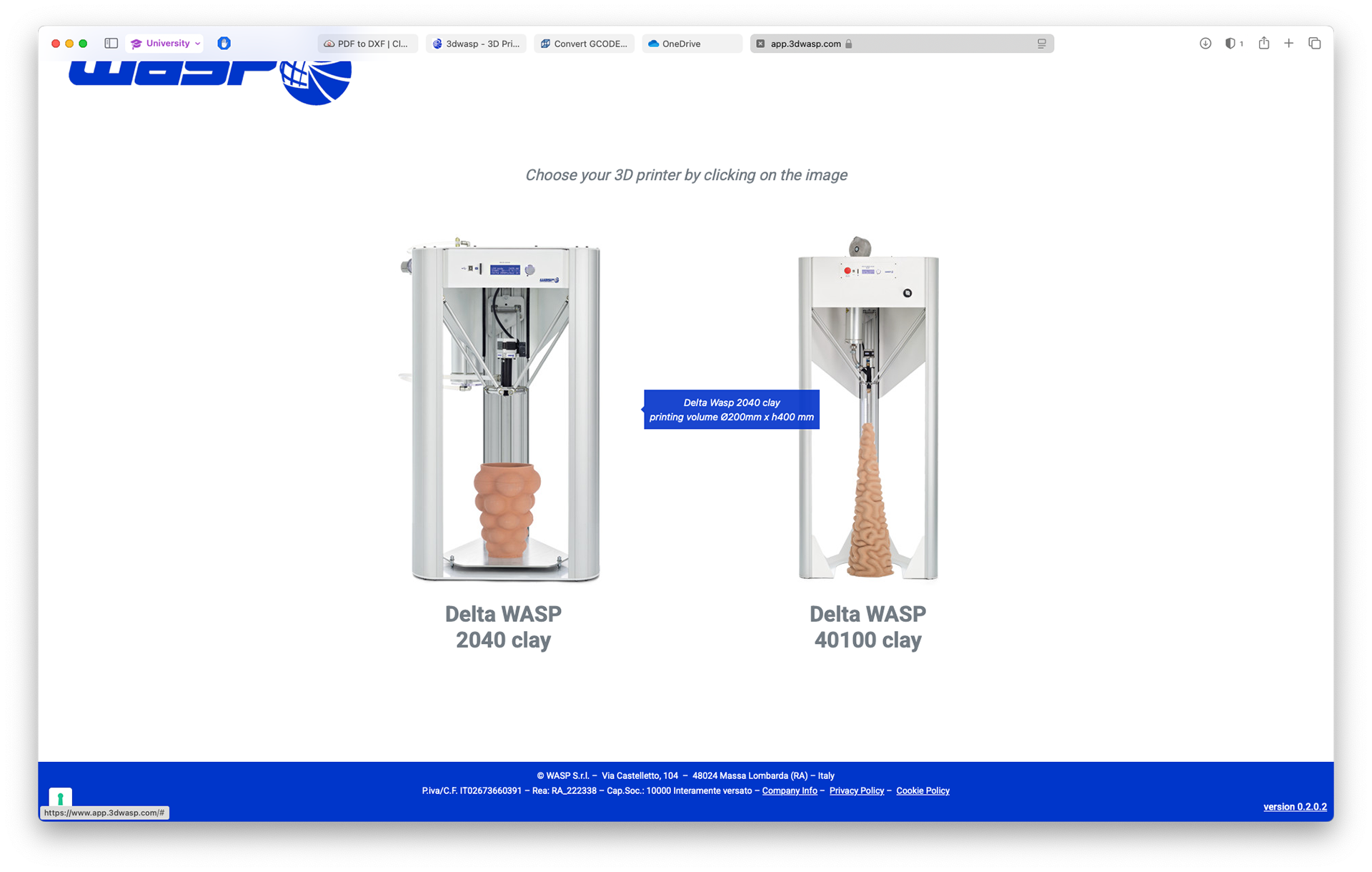

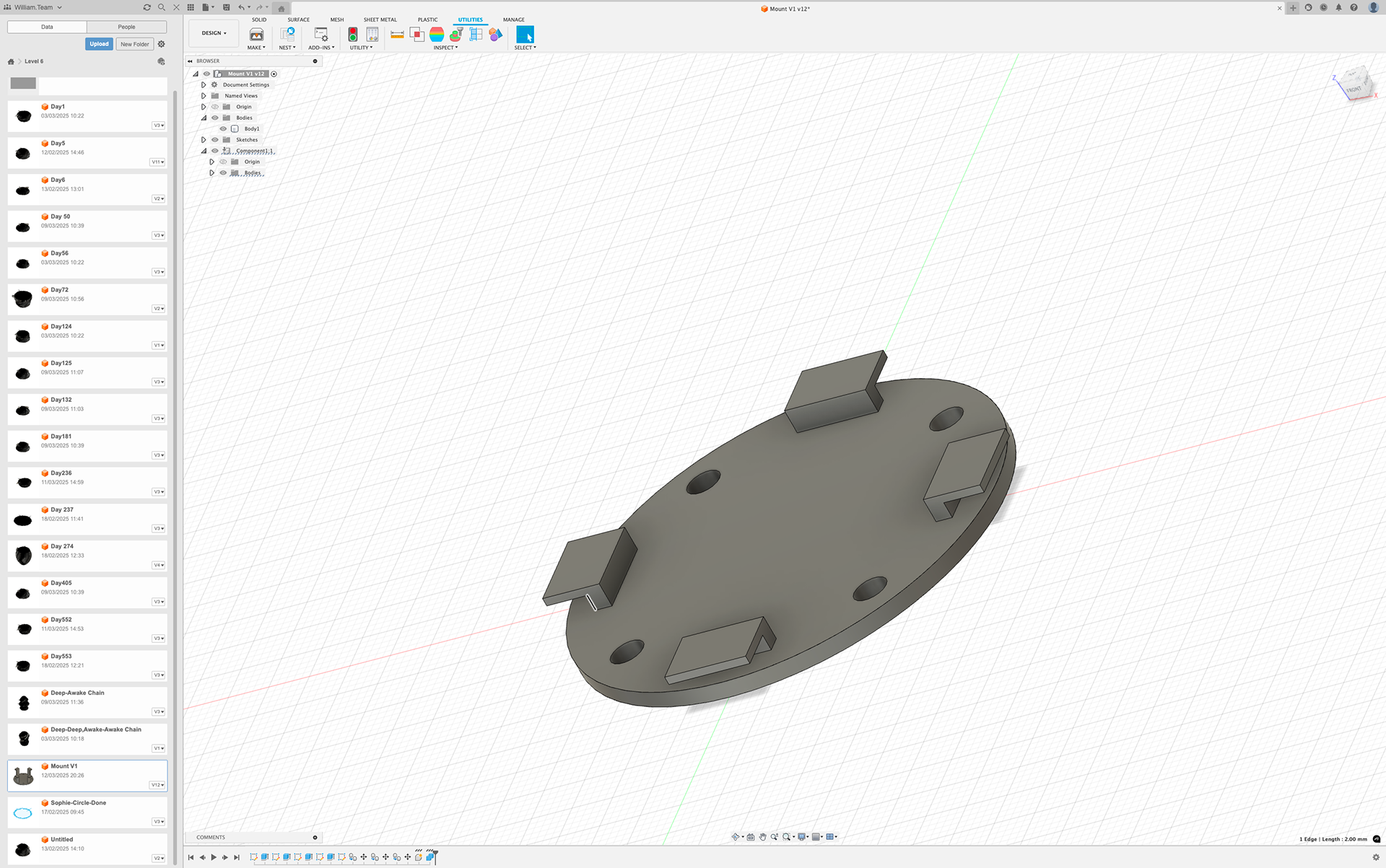

The two machines the software is designed for

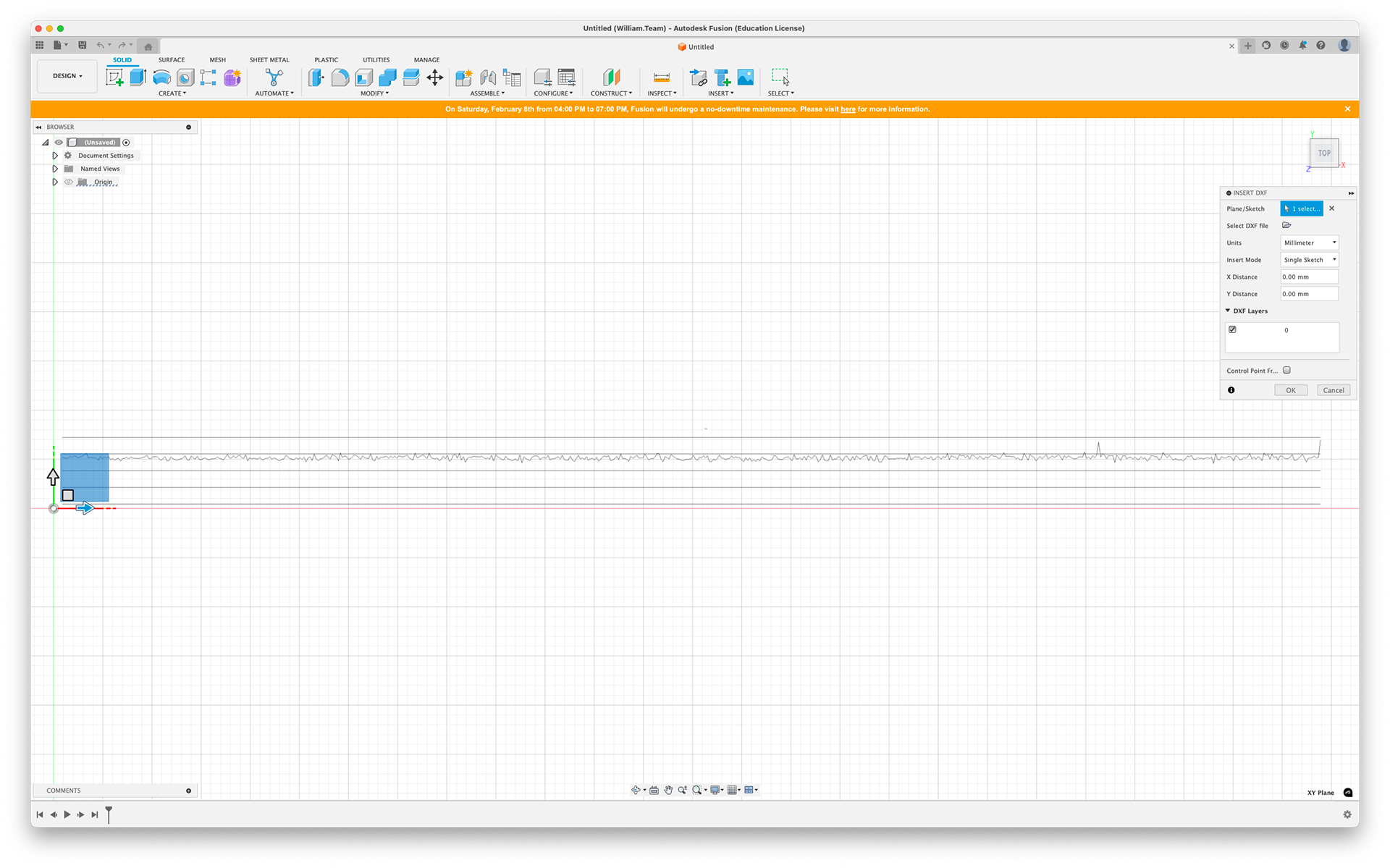

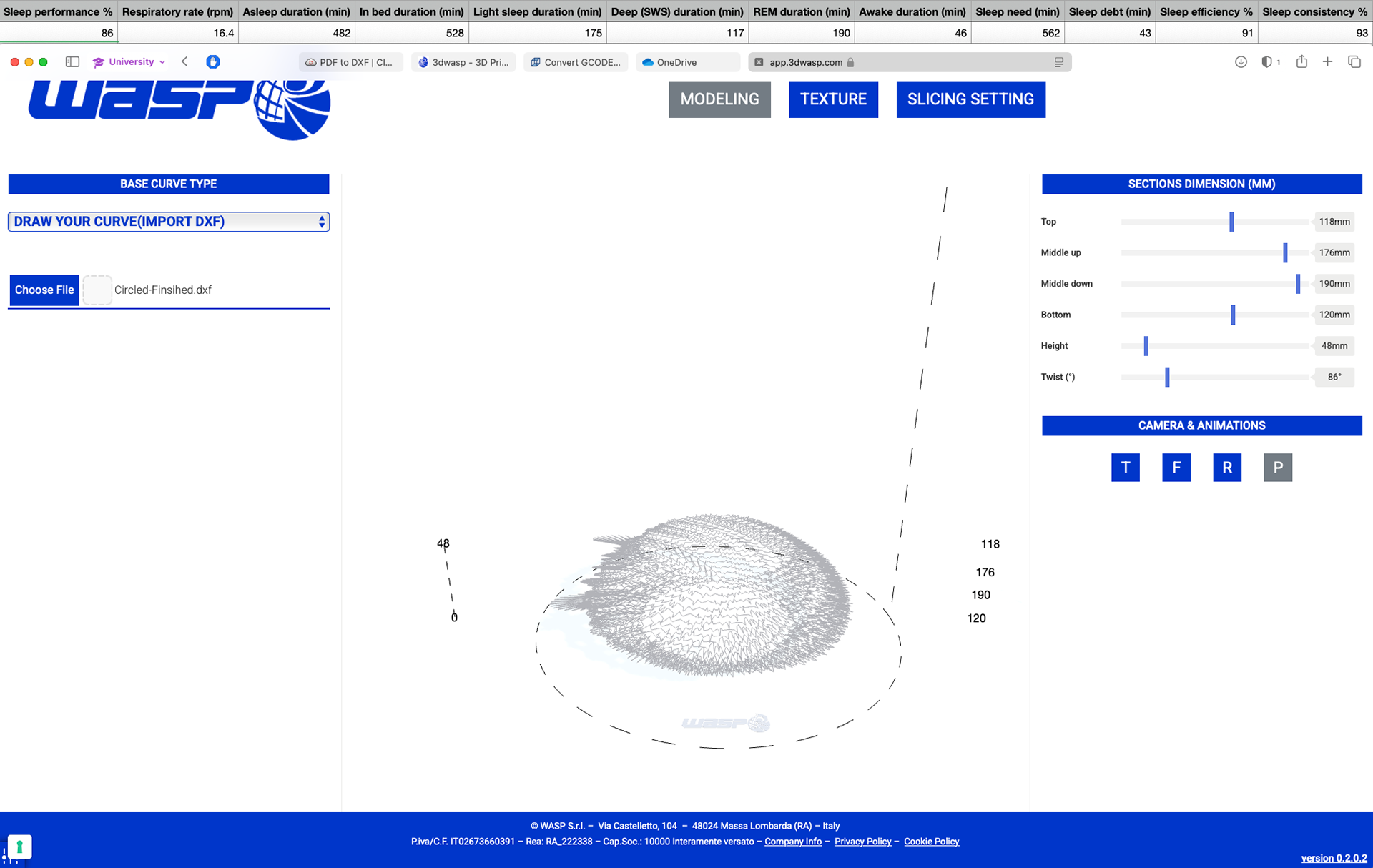

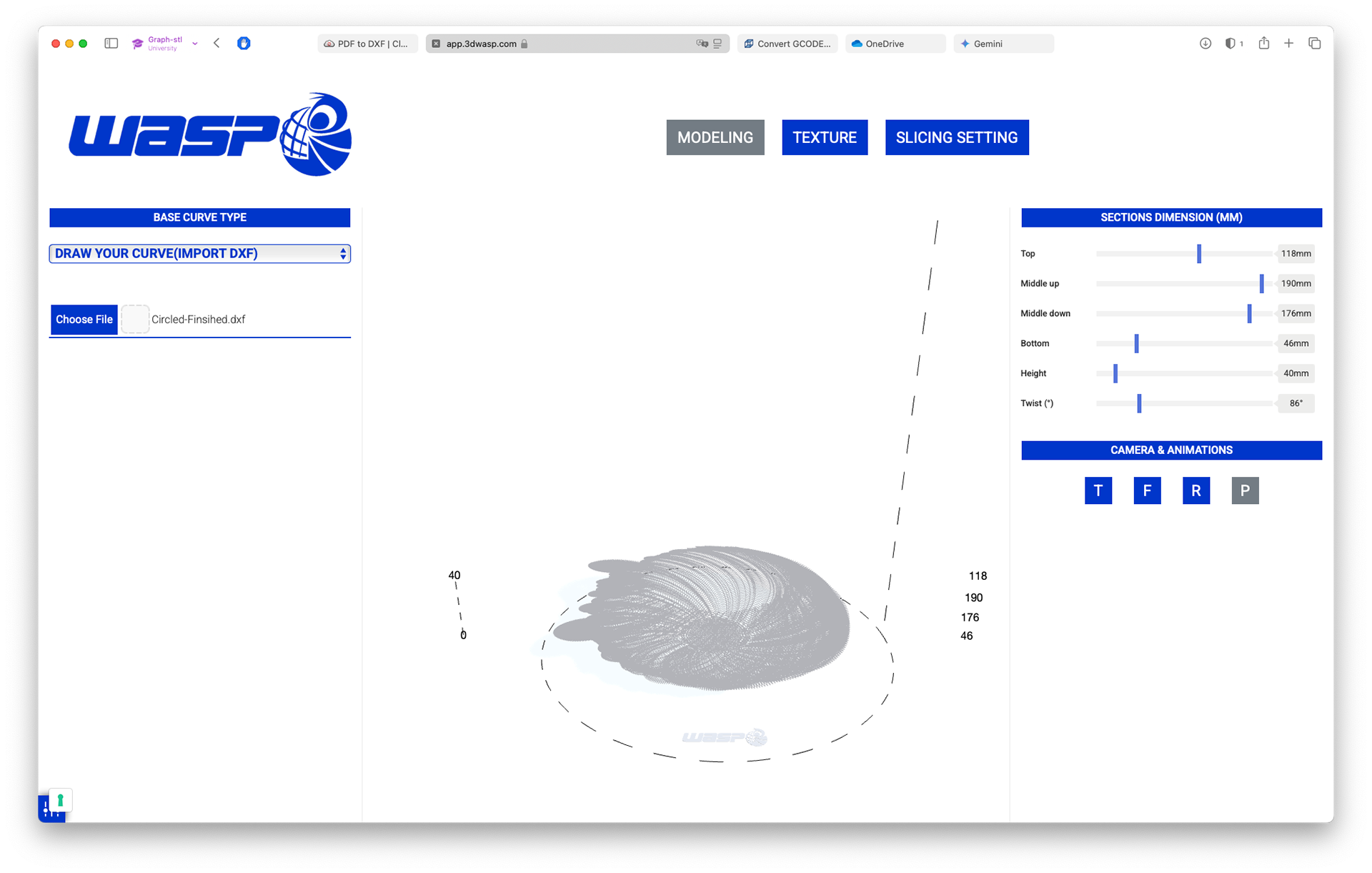

The dxf import and model settings

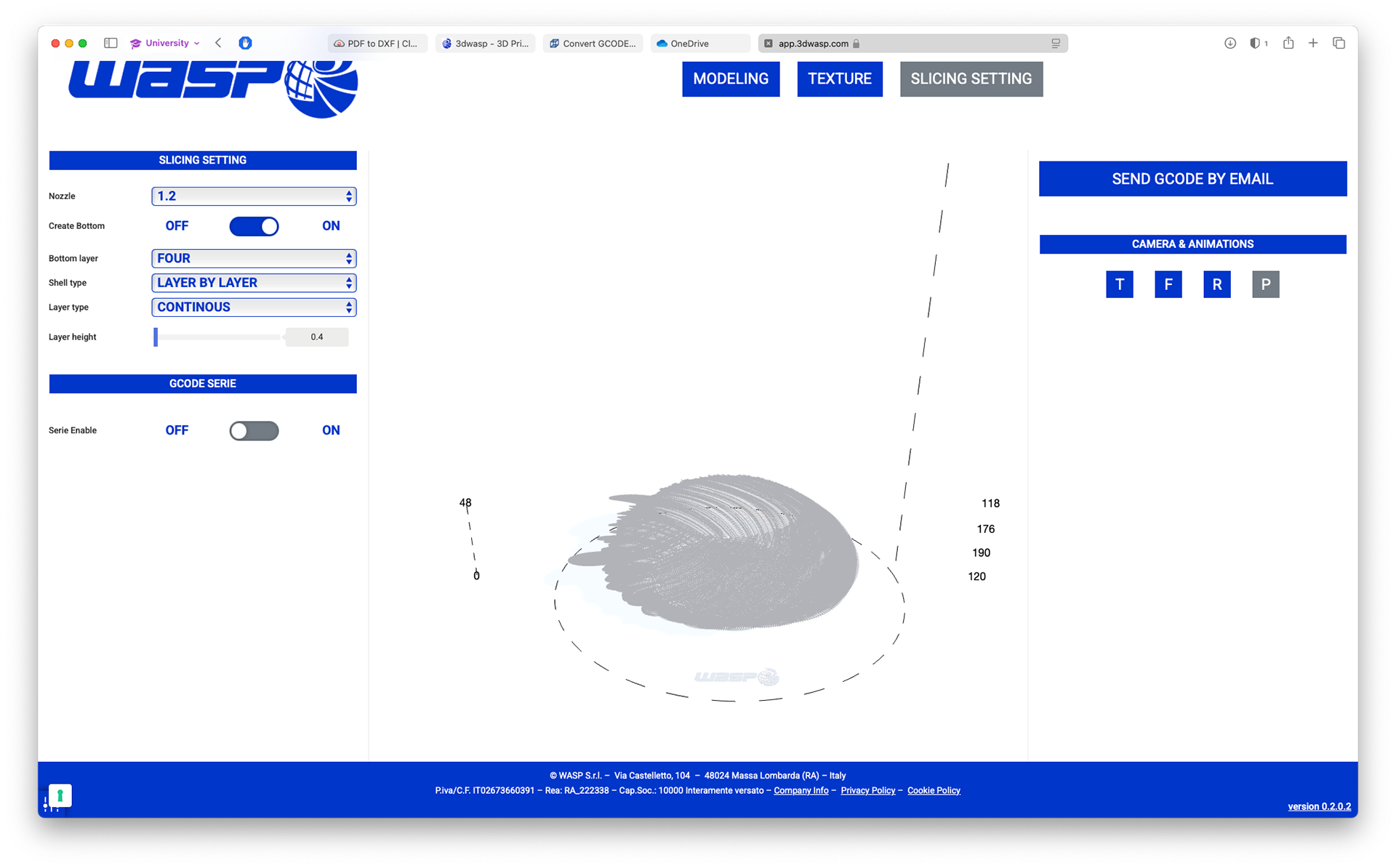

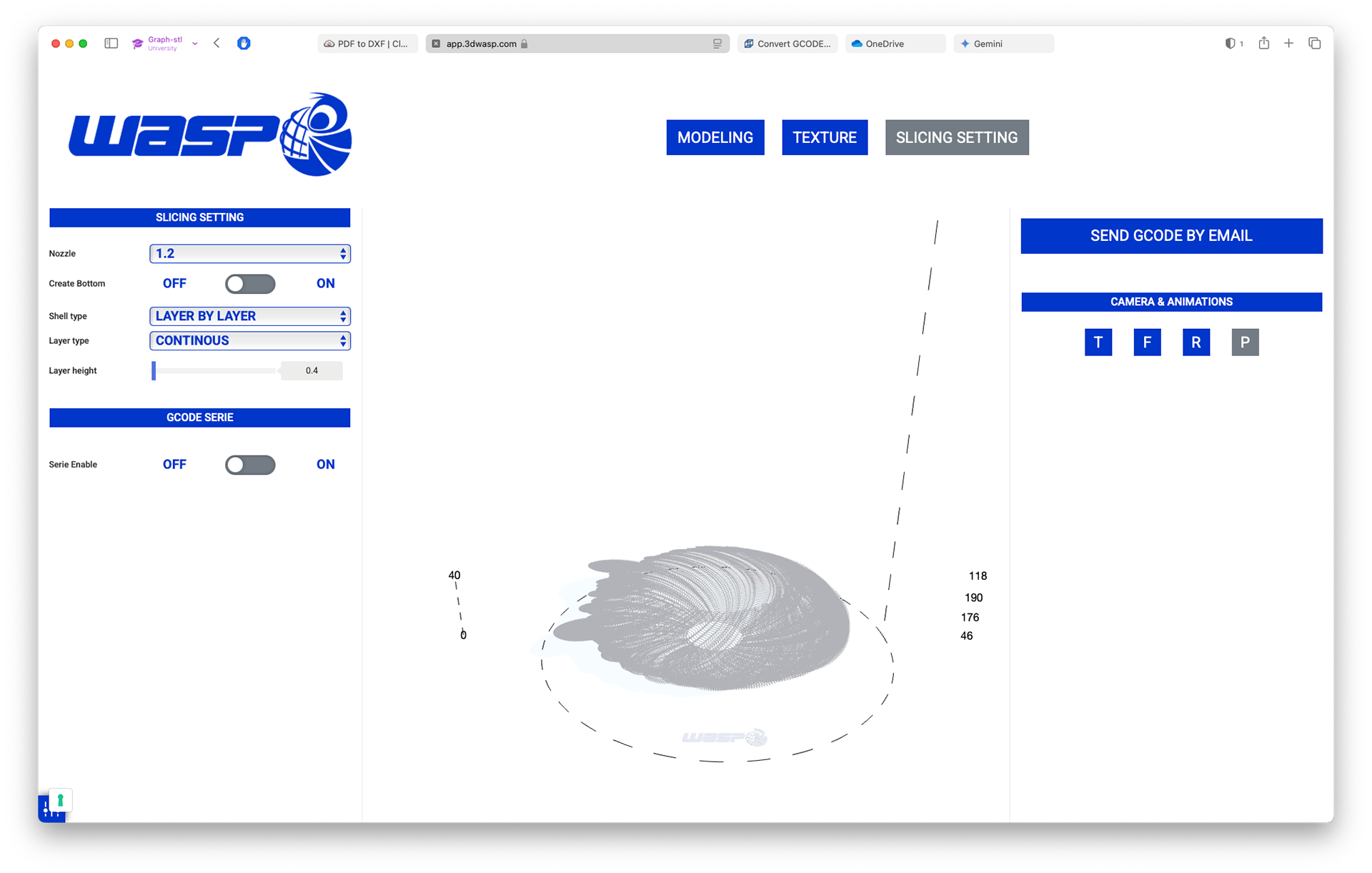

The slicing settings

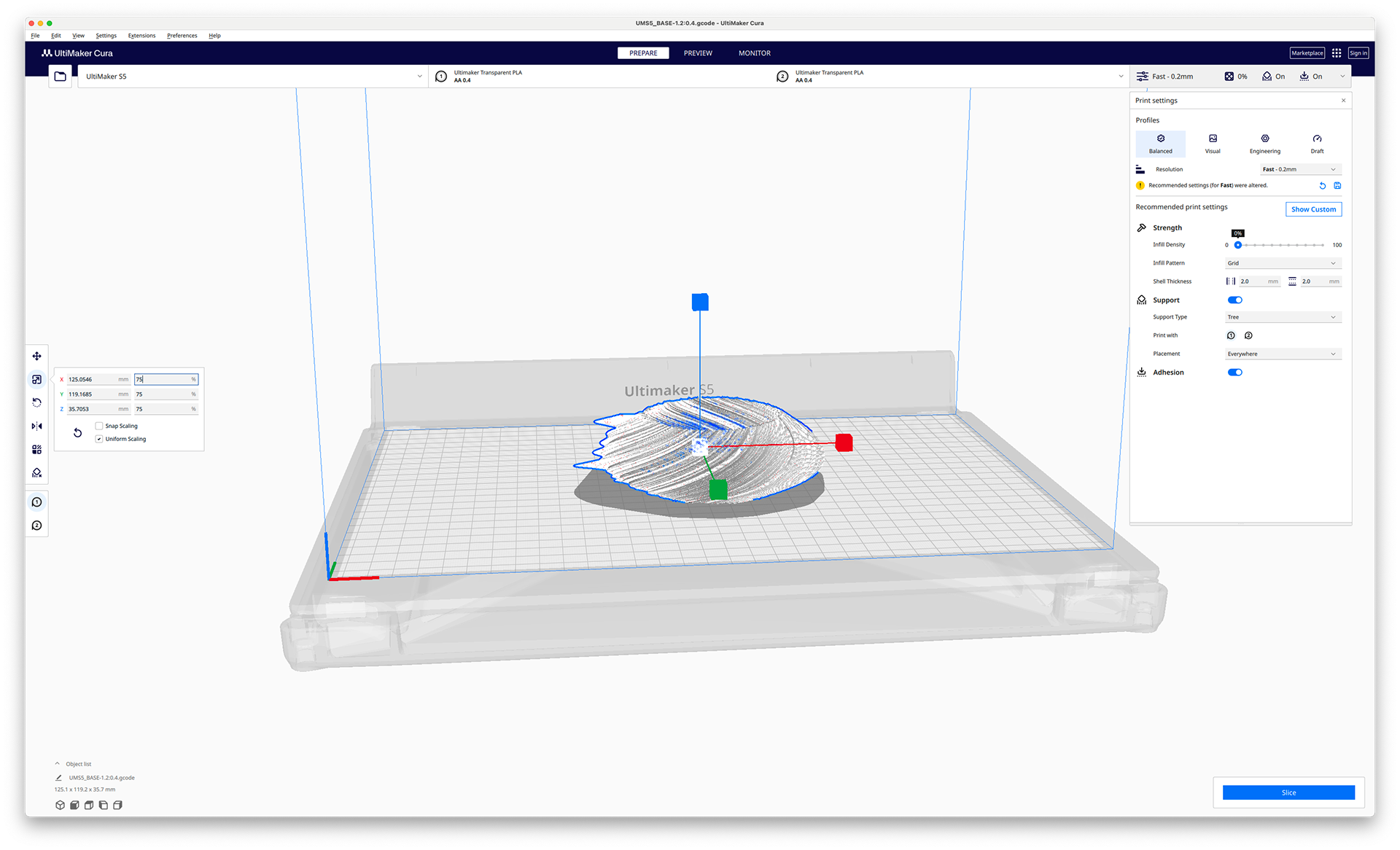

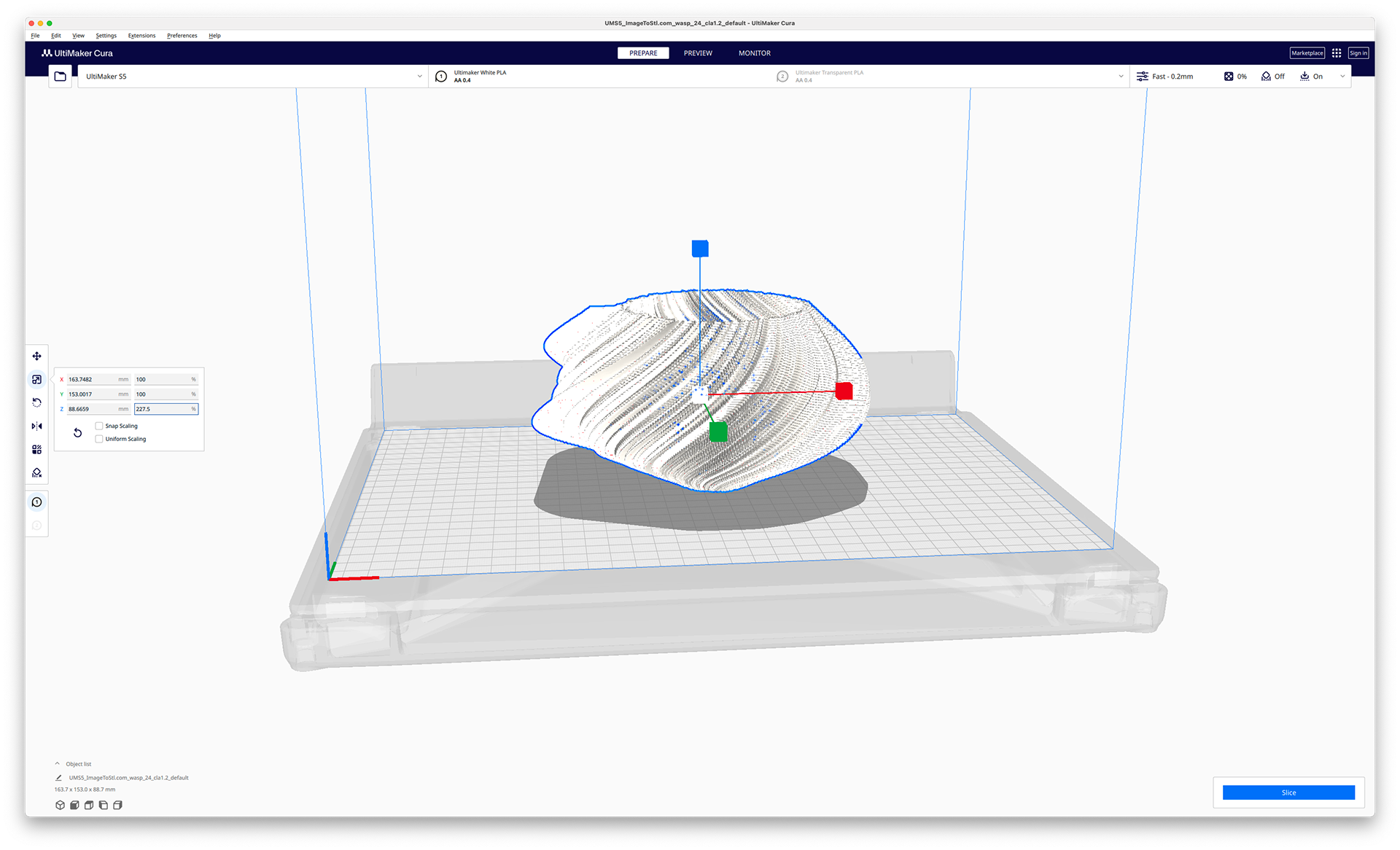

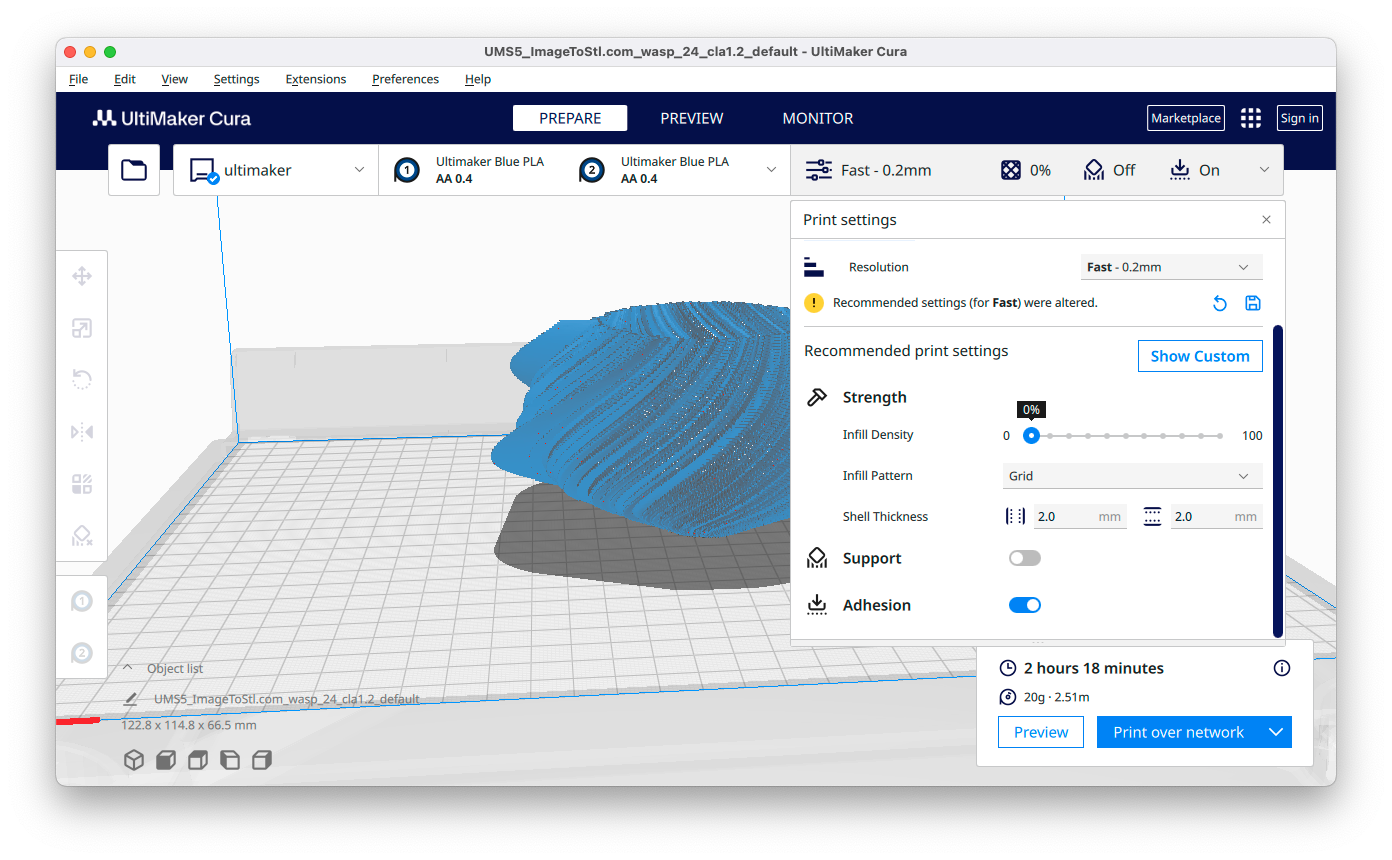

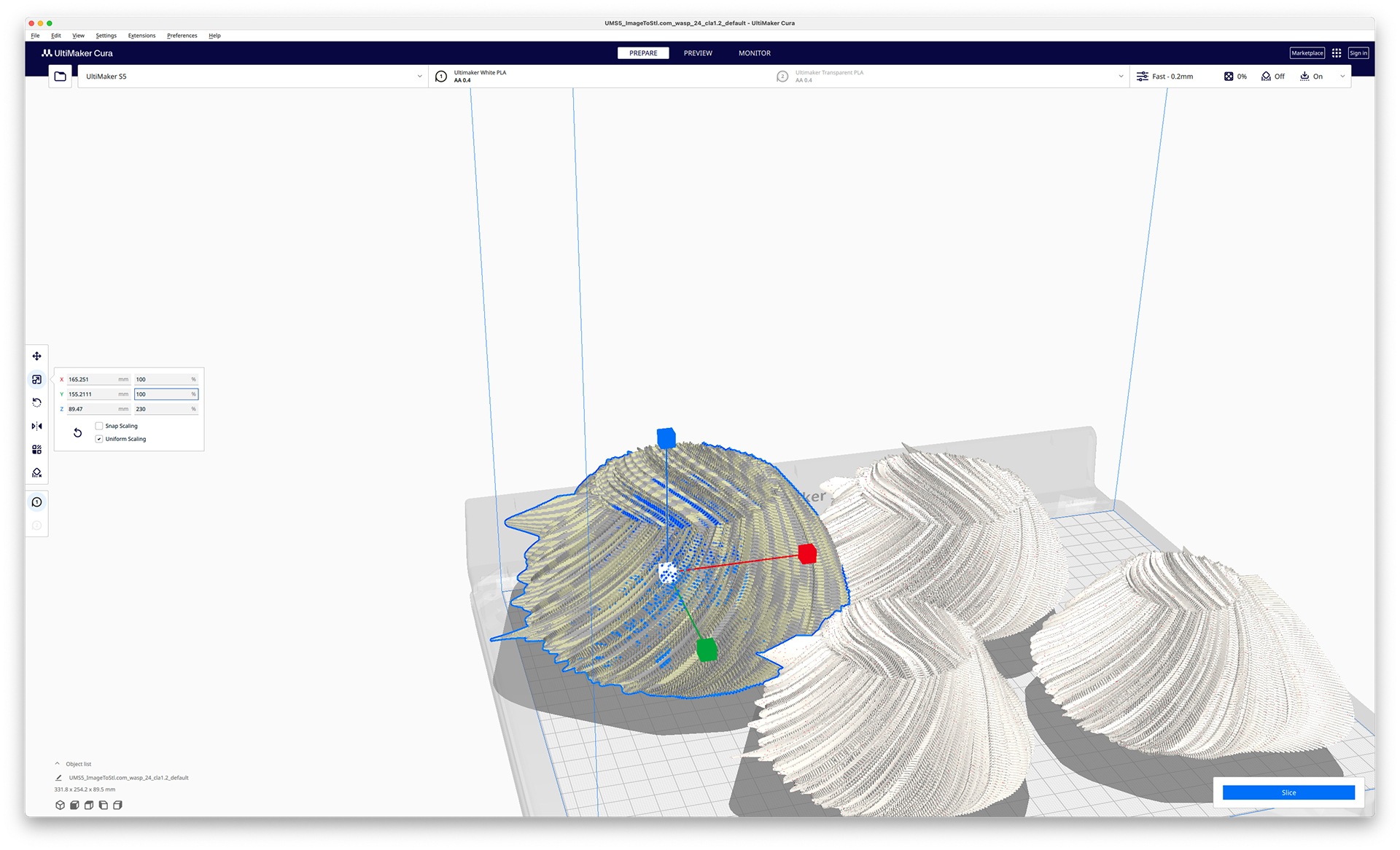

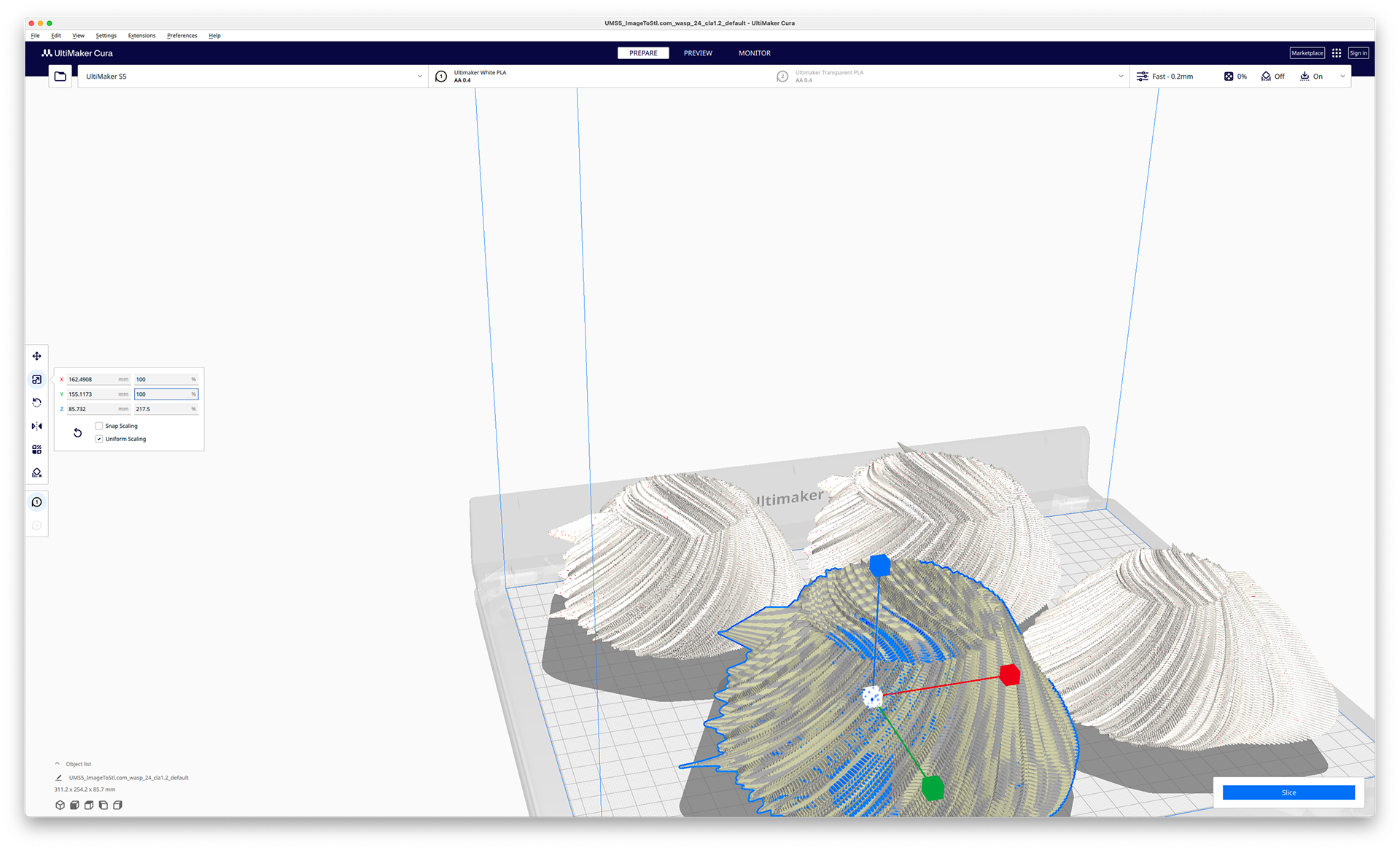

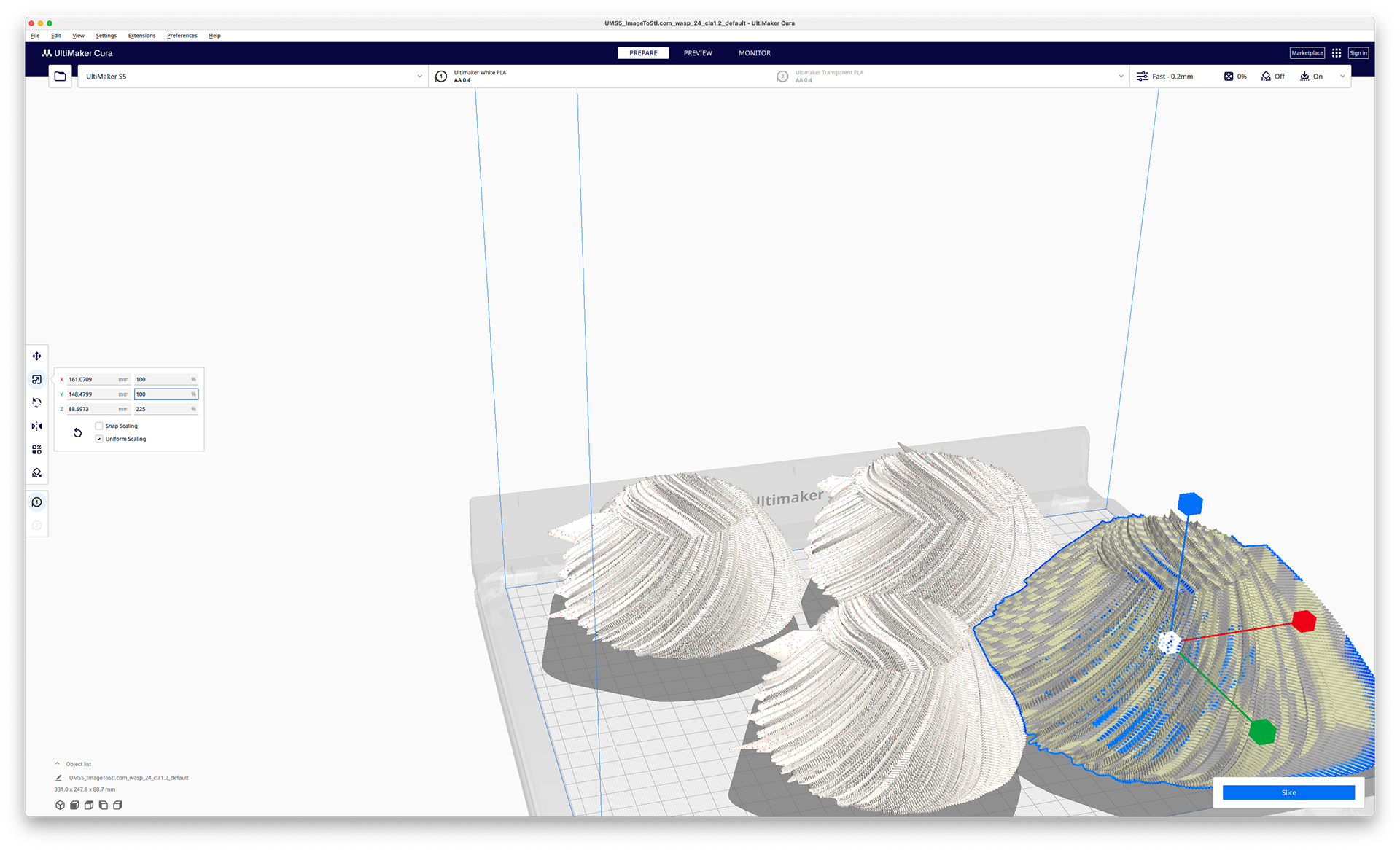

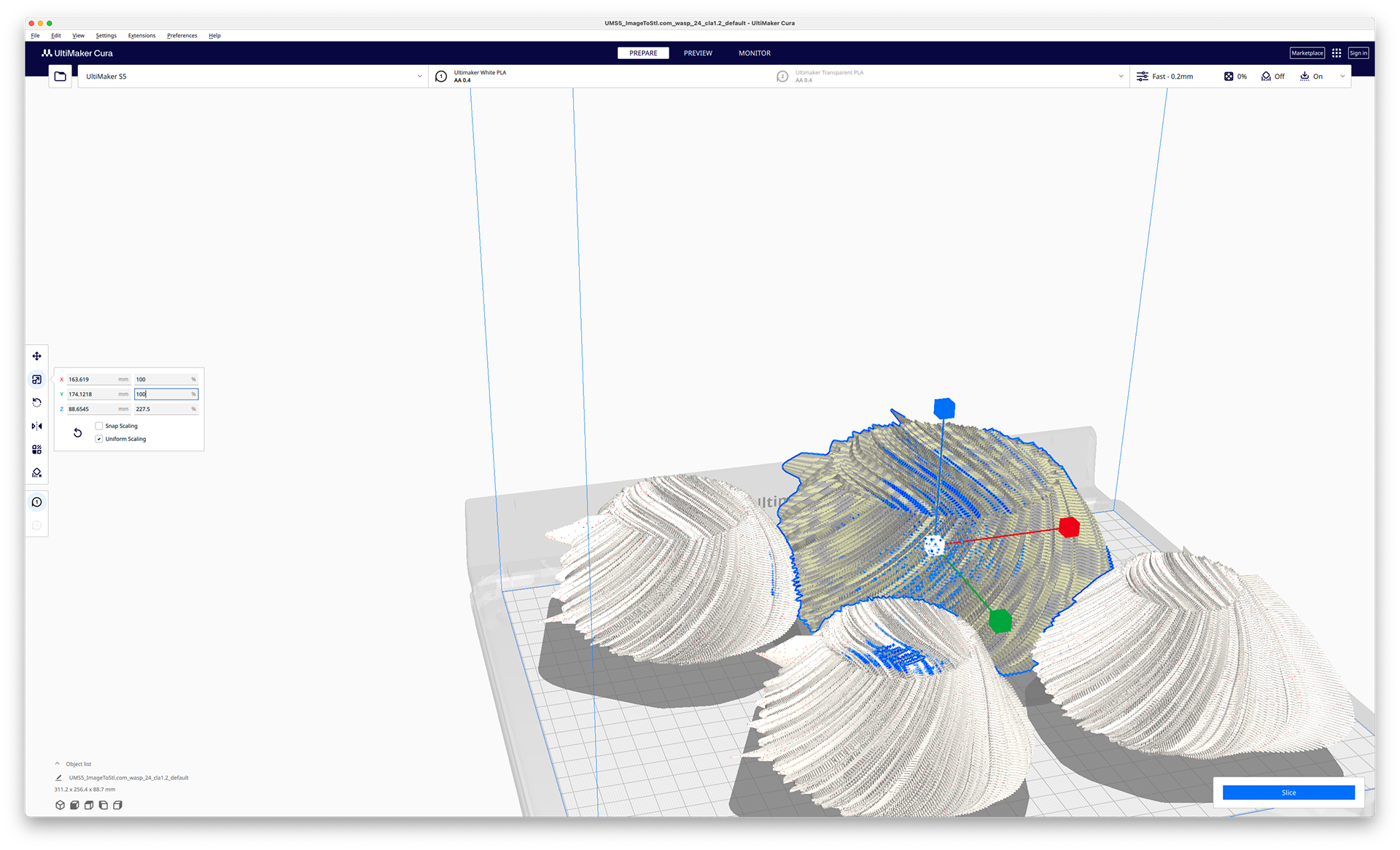

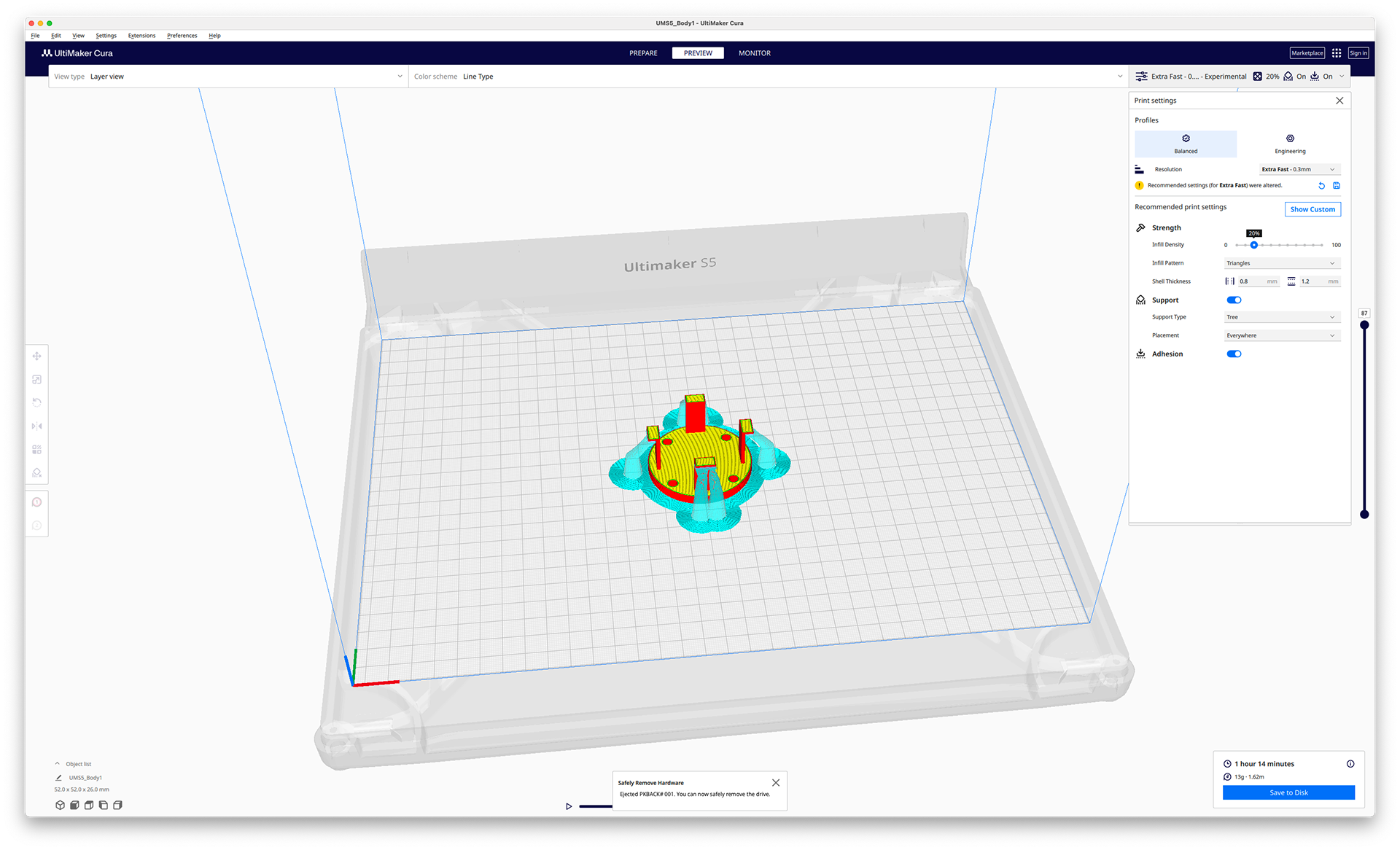

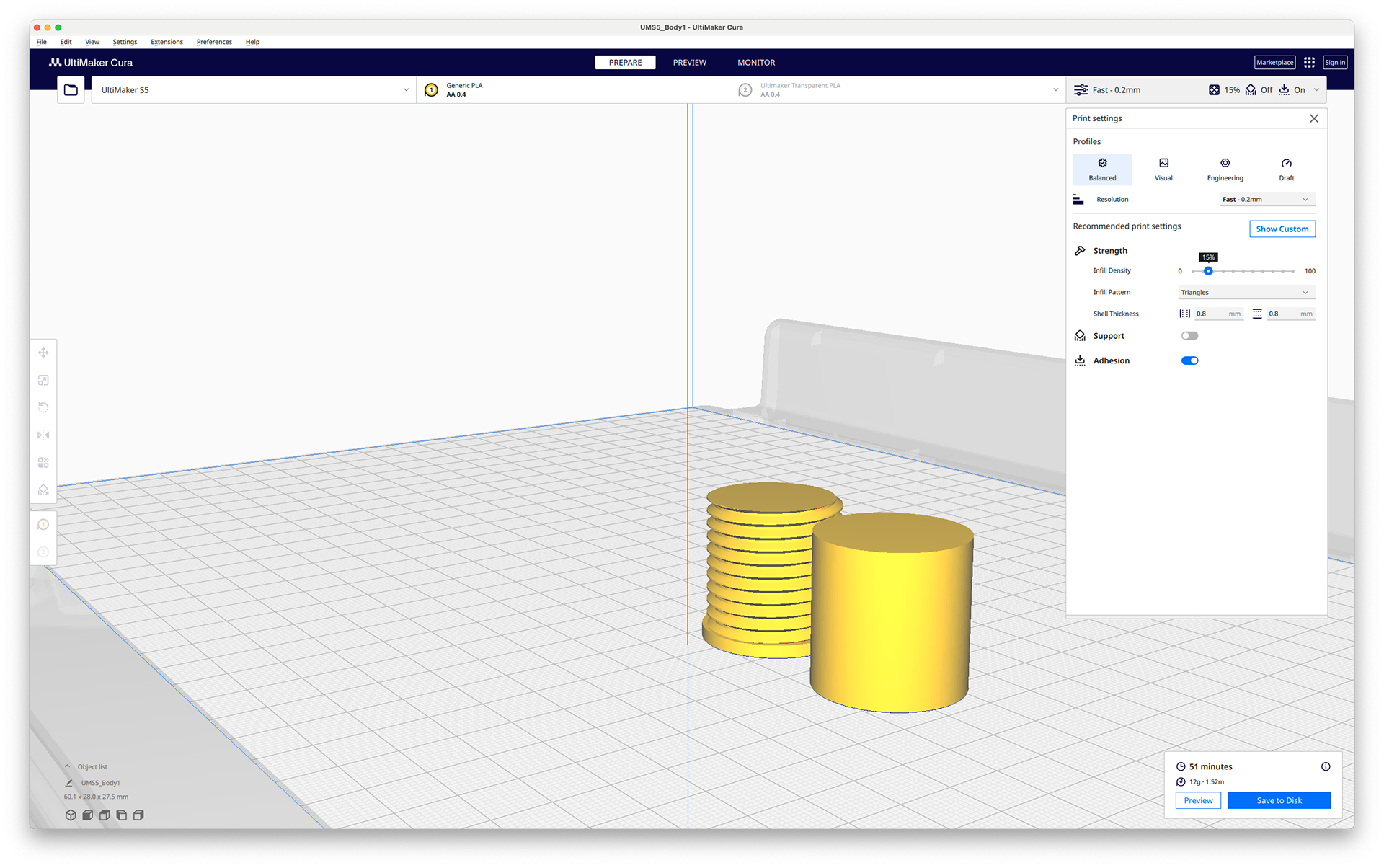

Cura settings

Model Settings

Slicer Settings

Scale Z axis

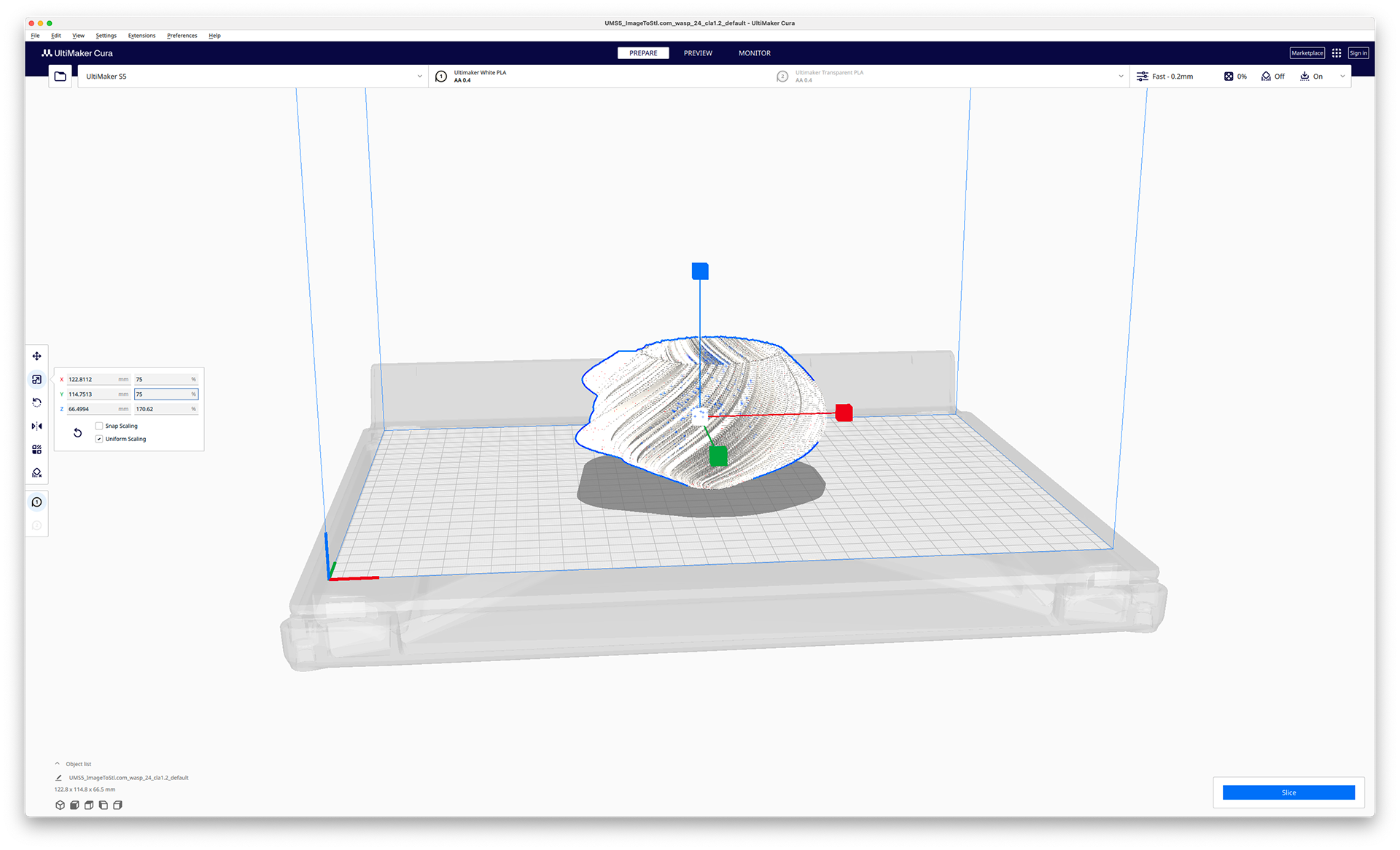

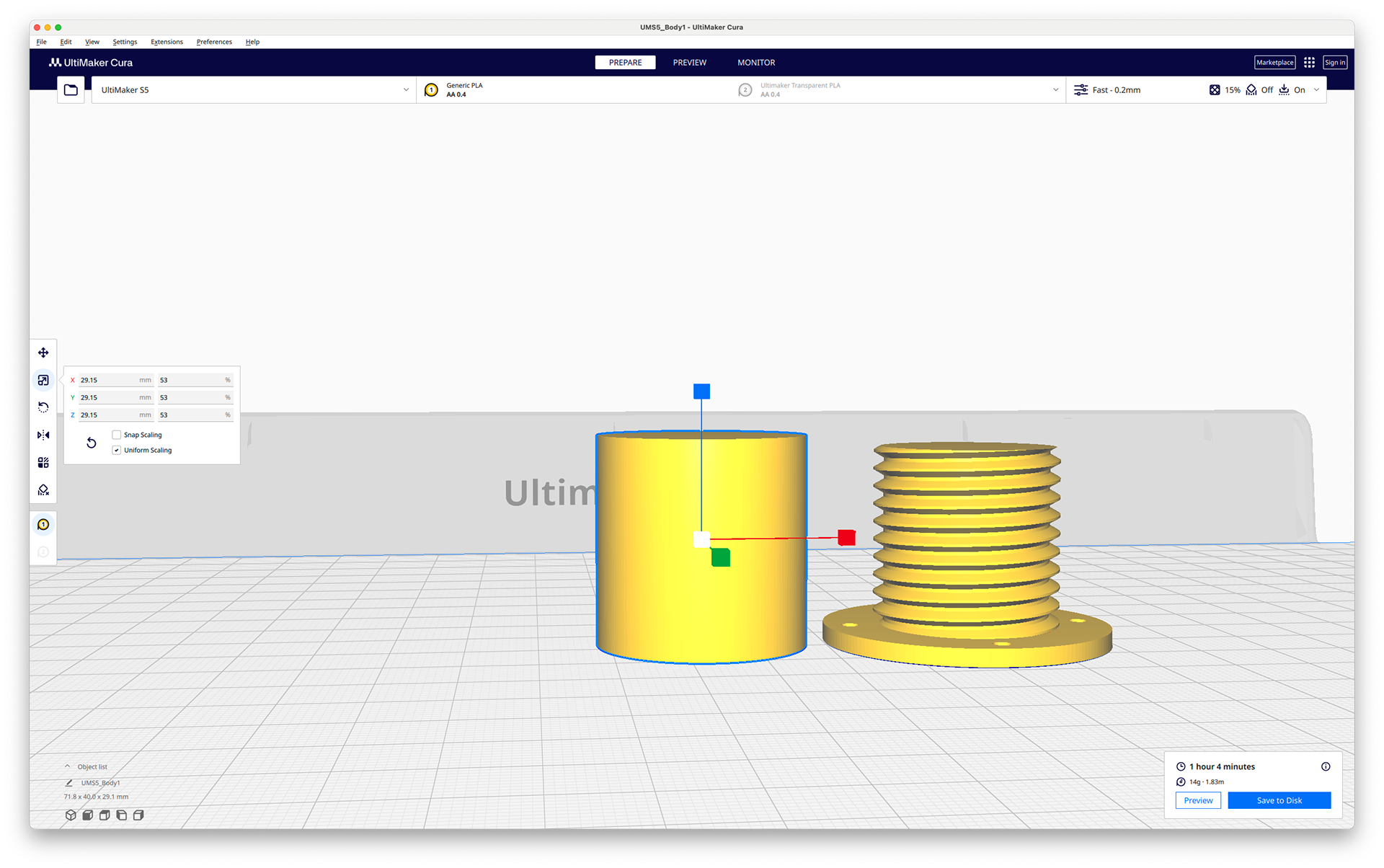

Uniformly scale down to 75%

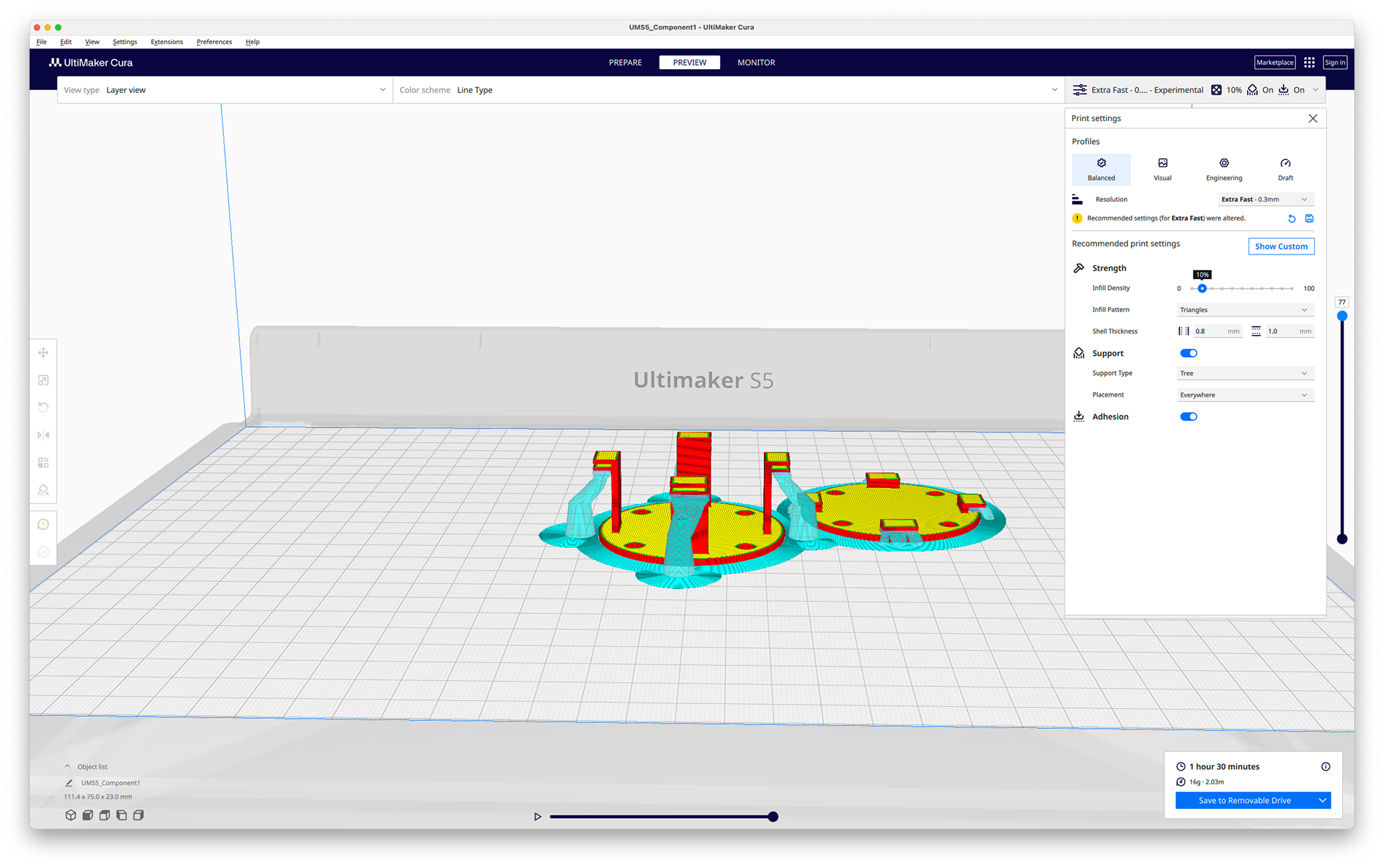

Cura Print Settings and Print Time

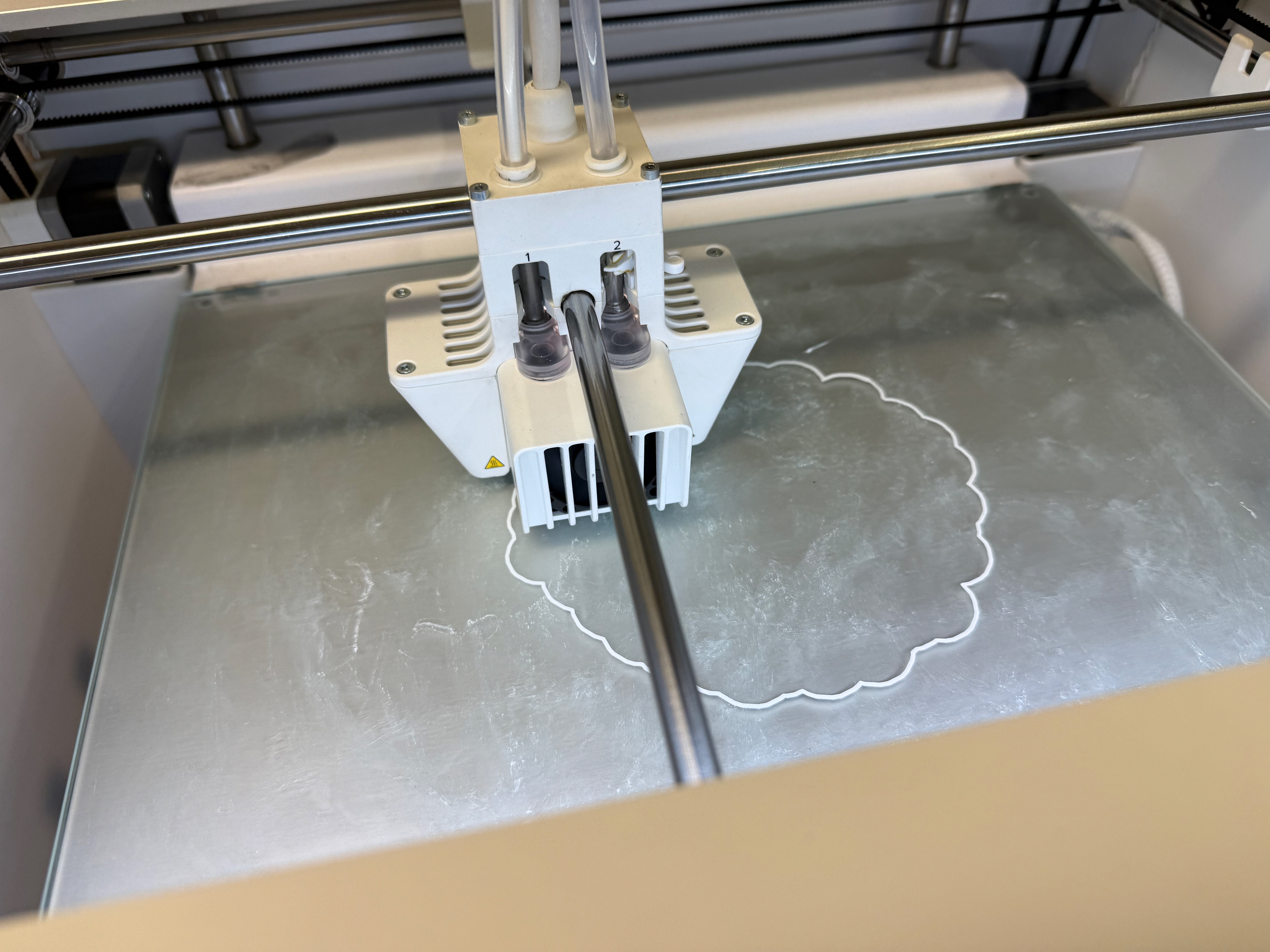

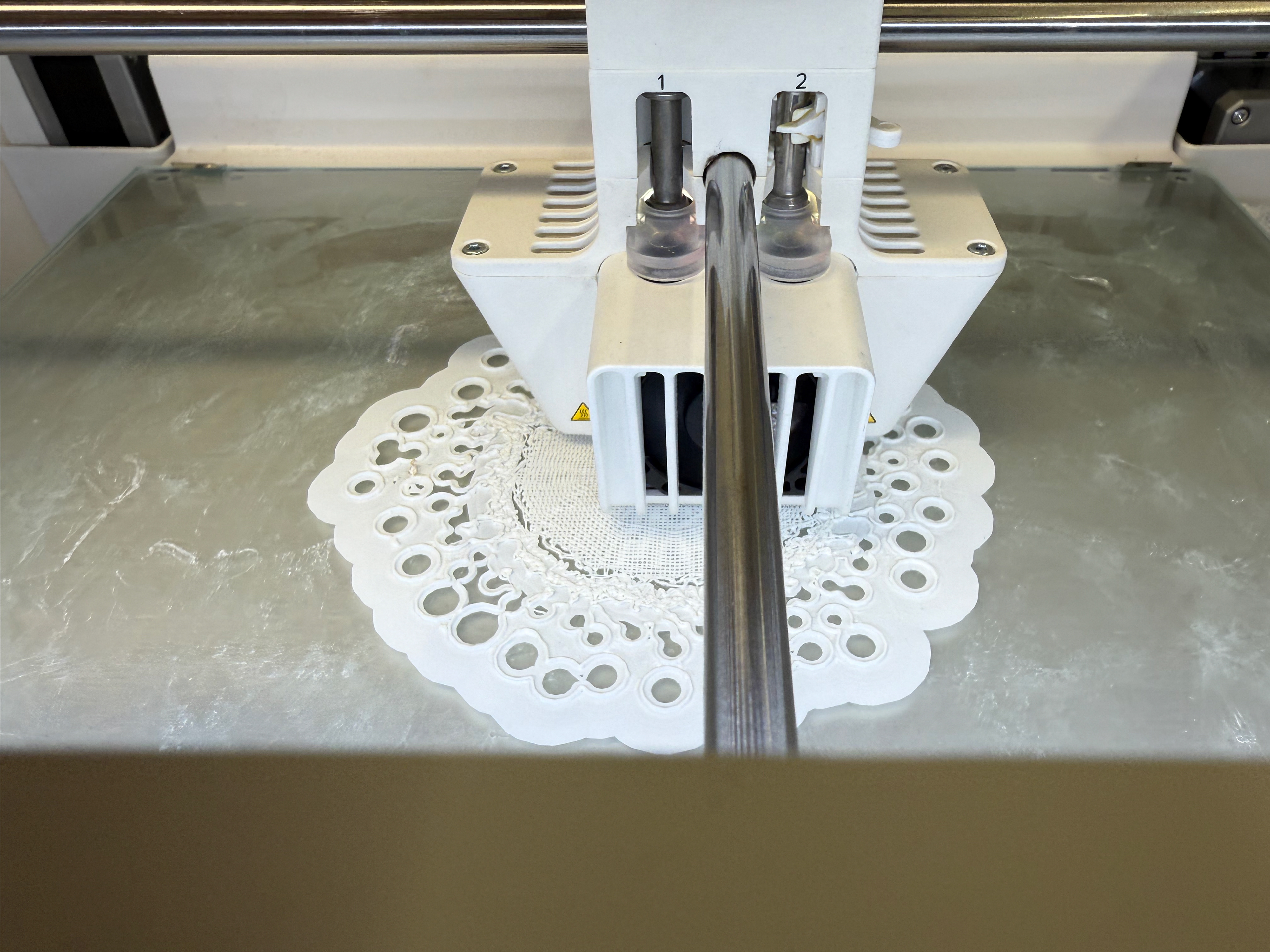

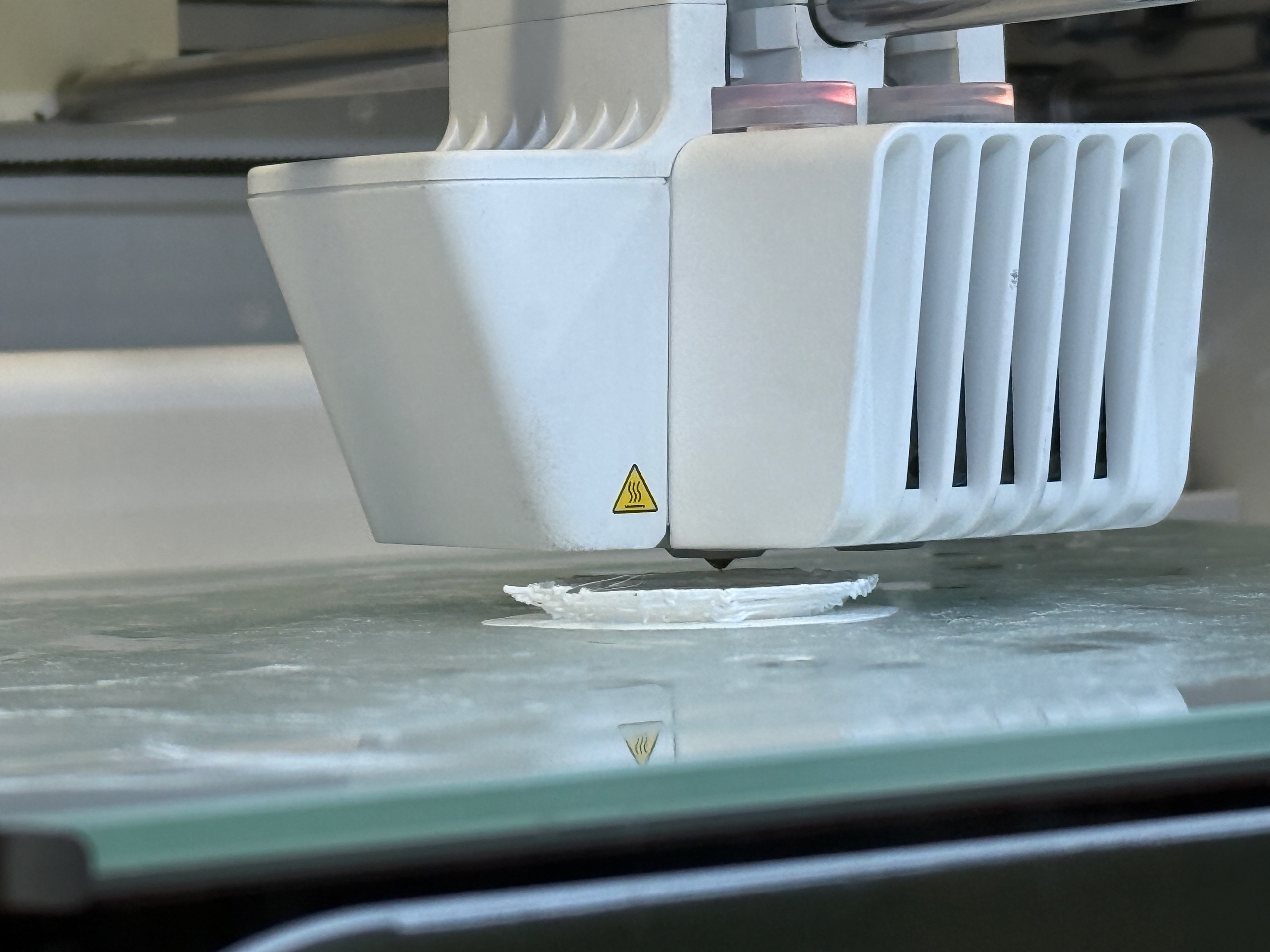

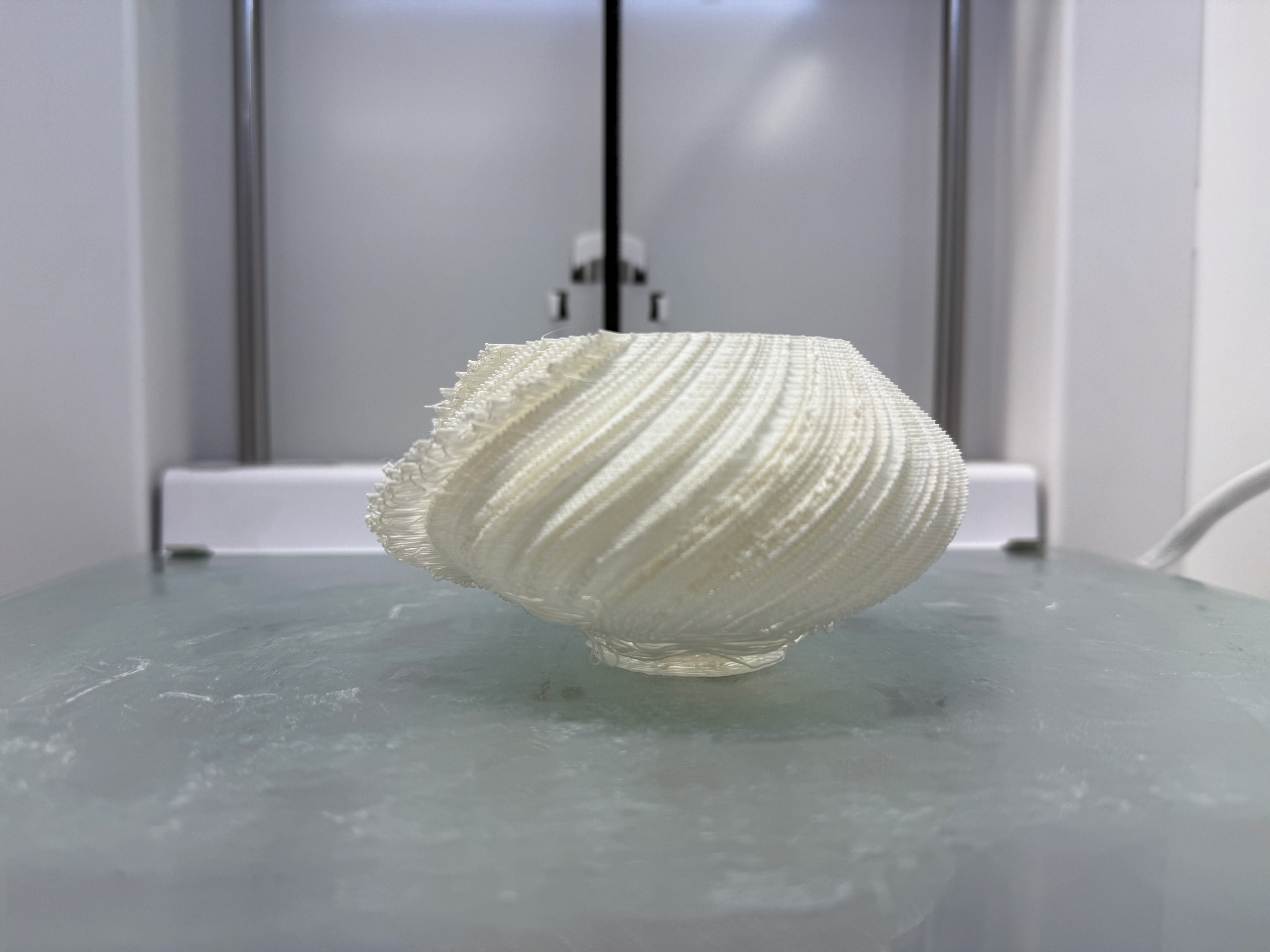

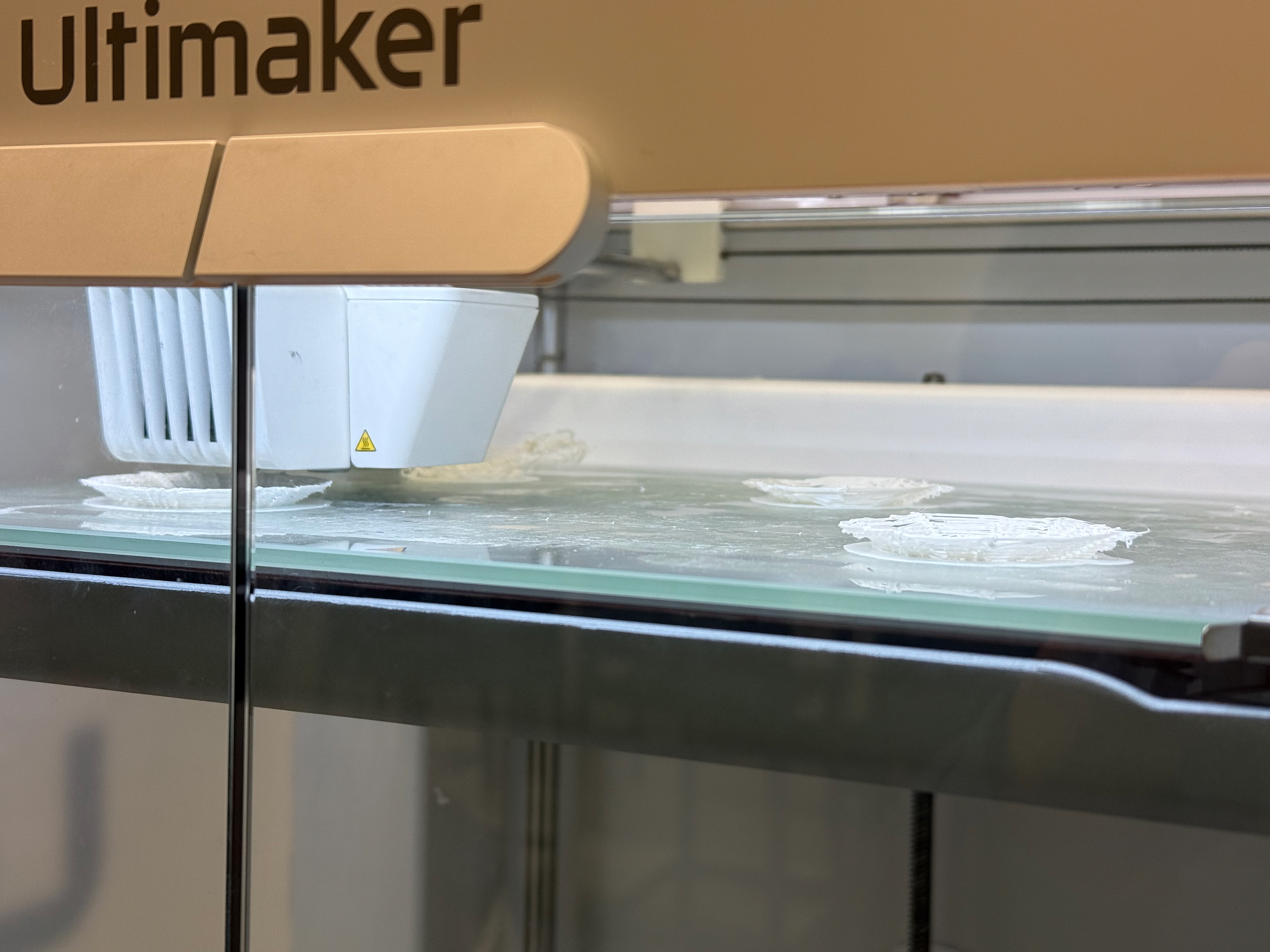

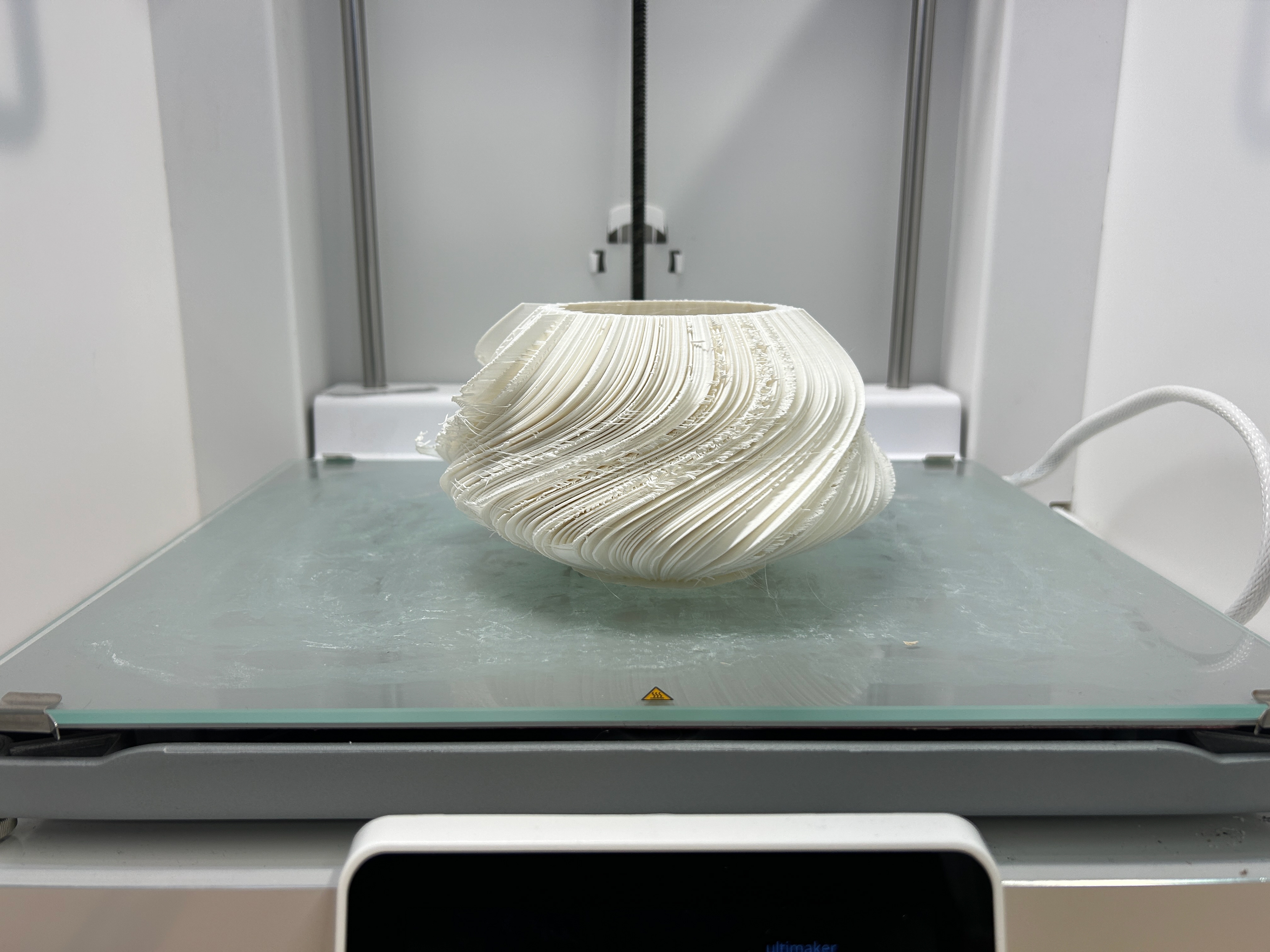

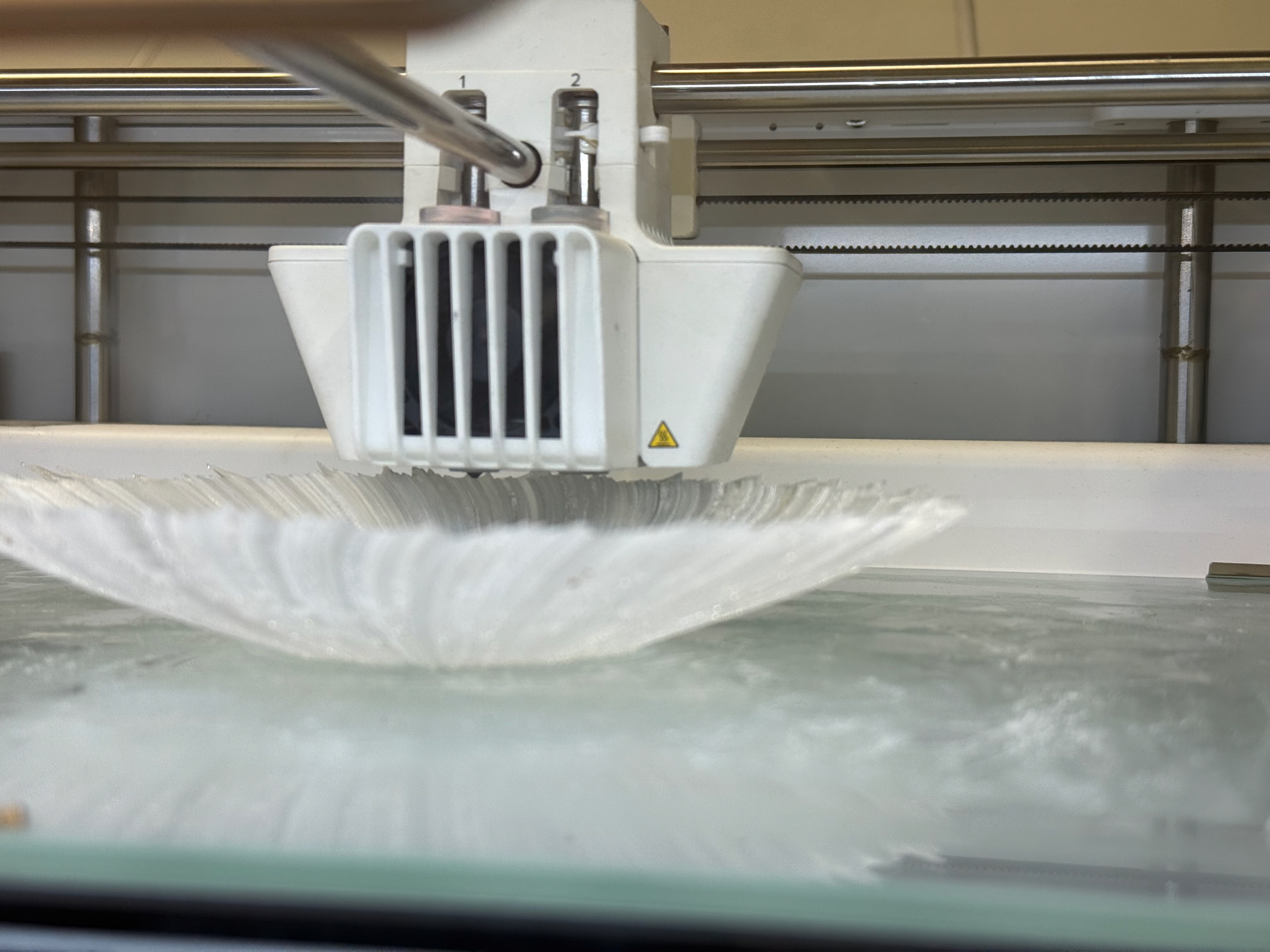

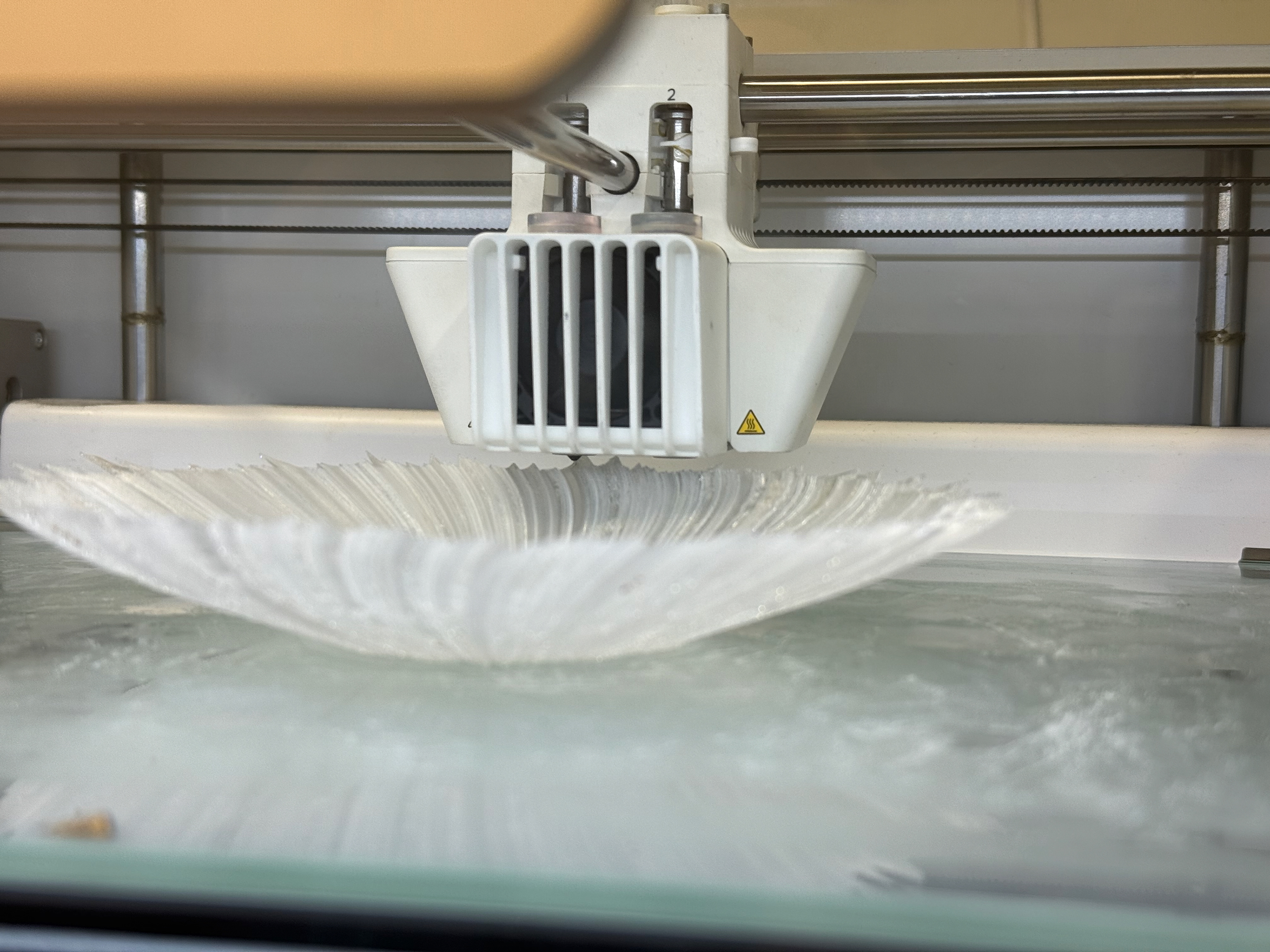

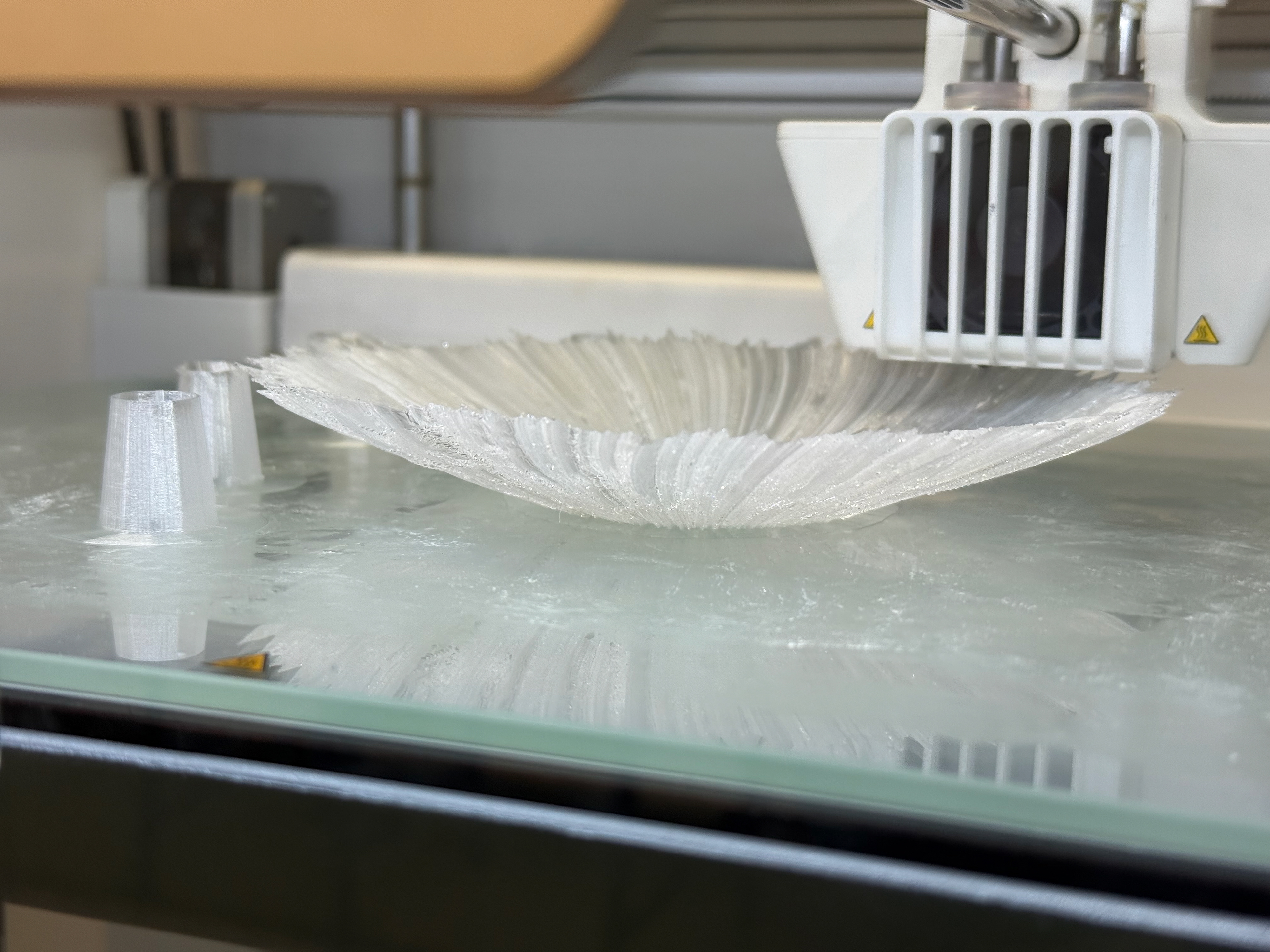

Start of print

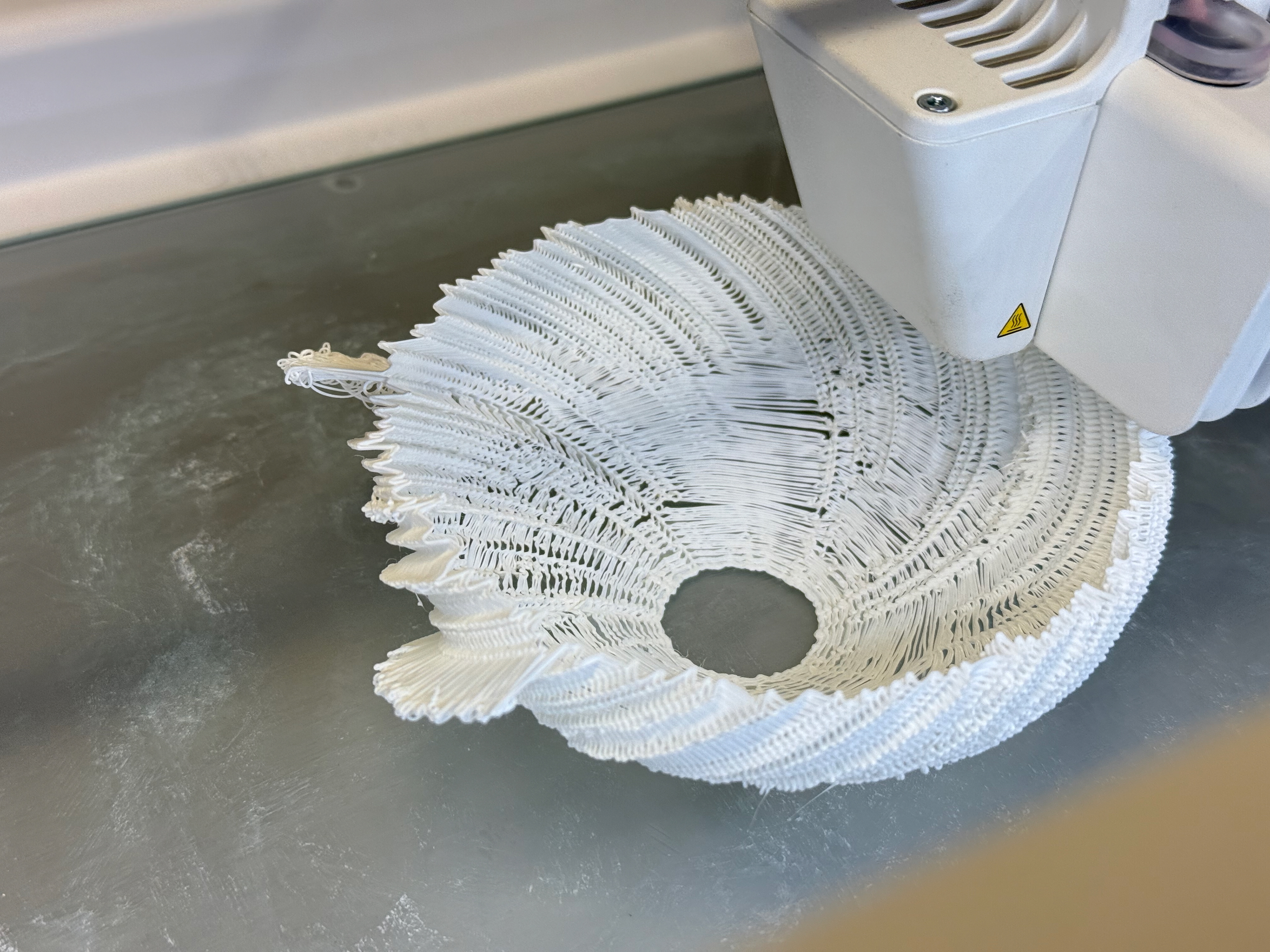

The opening up seems to be holding well

Continues to be successful

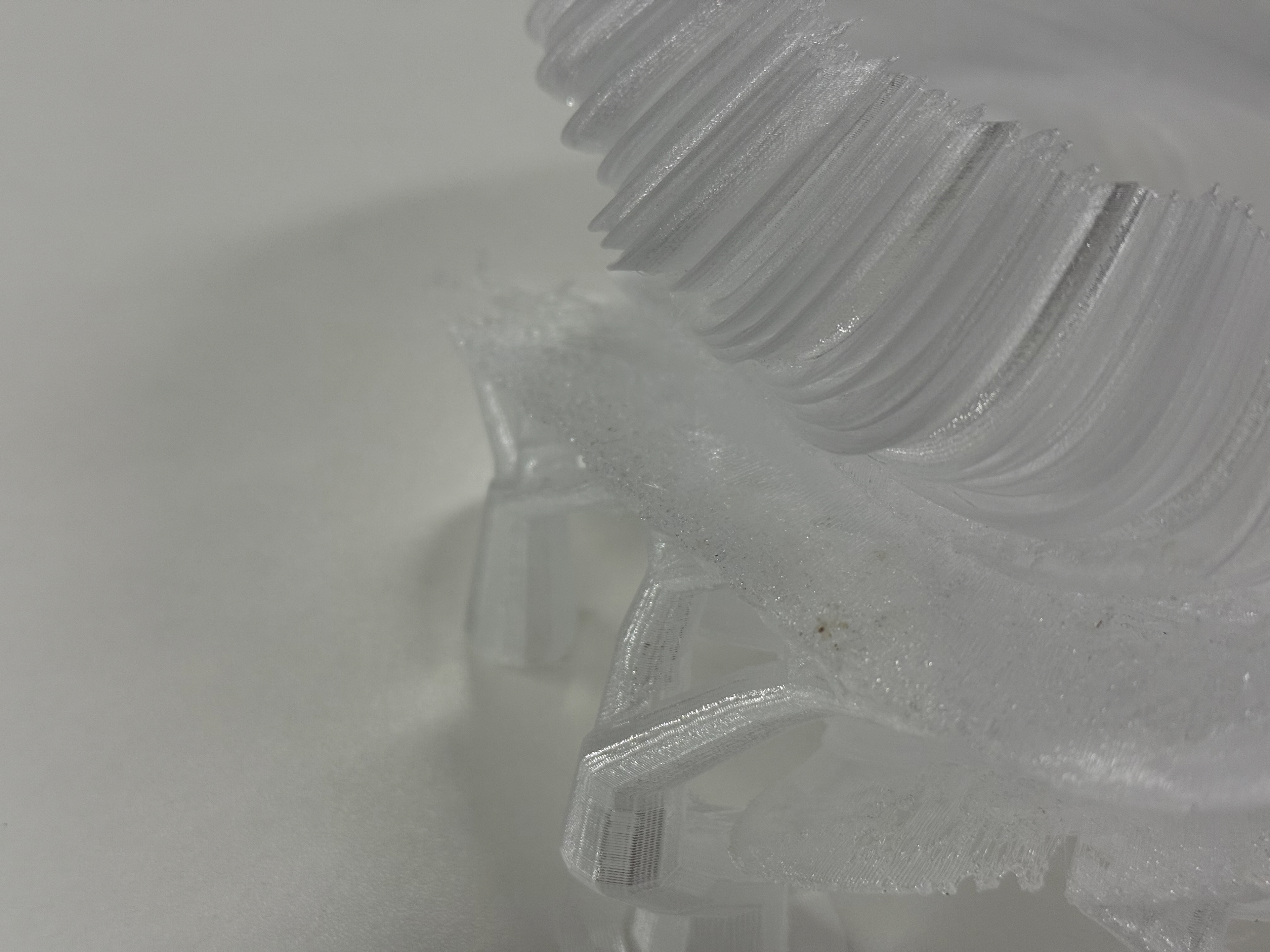

The inside could do with less spacing

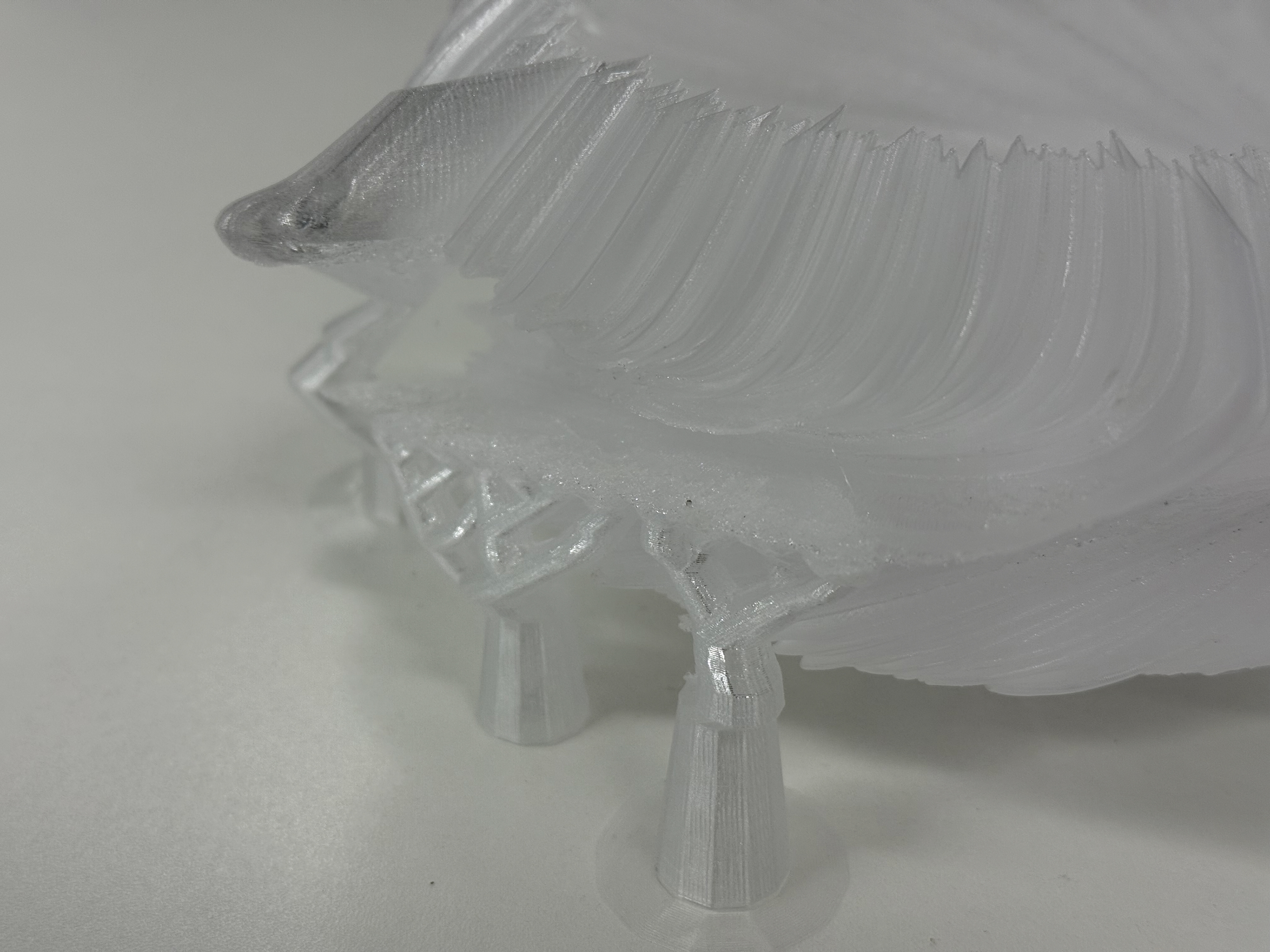

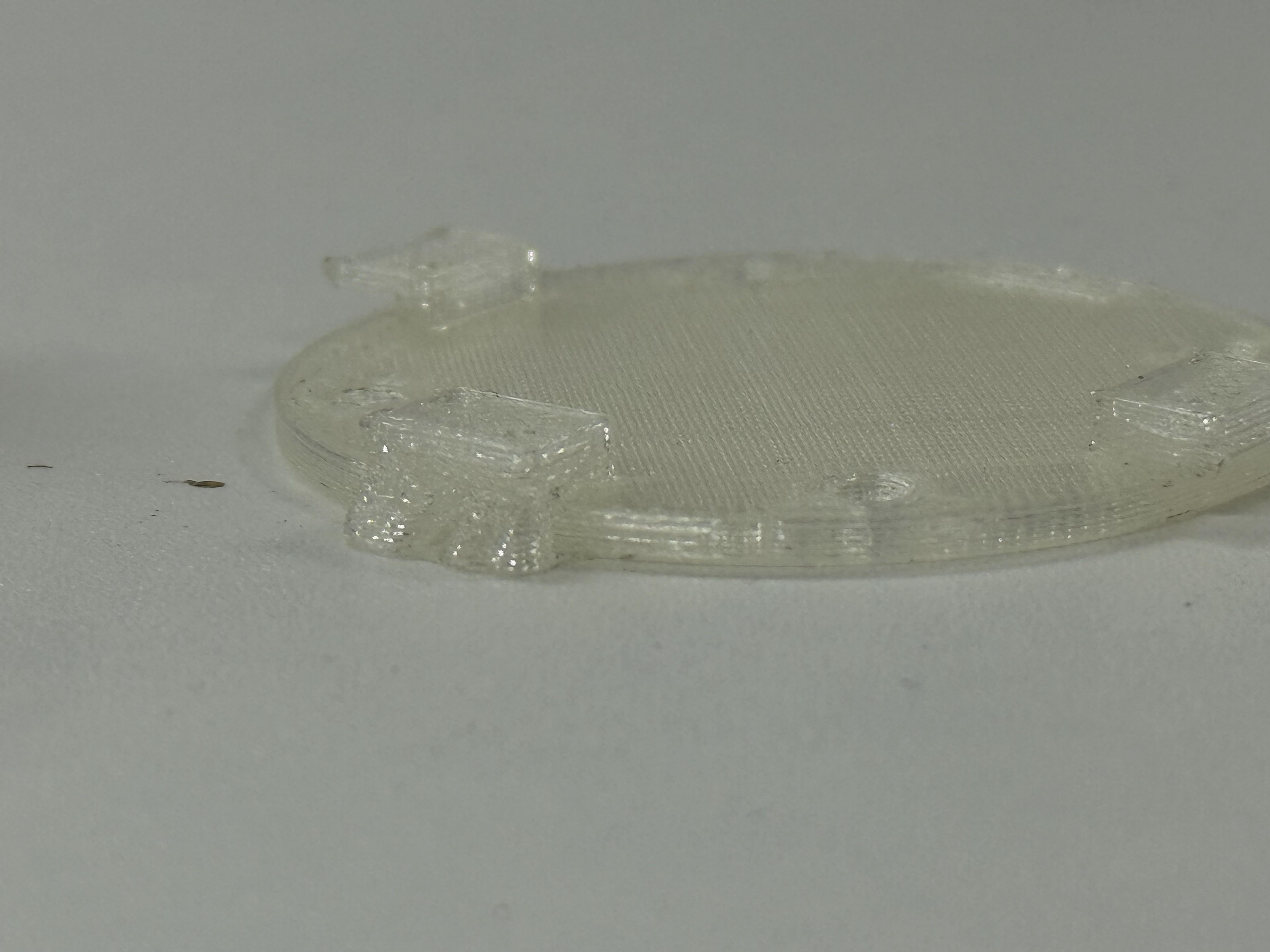

Few stray pieces of plastic

Past the widest point but now it's going to overlay

Print pattern changes a few times

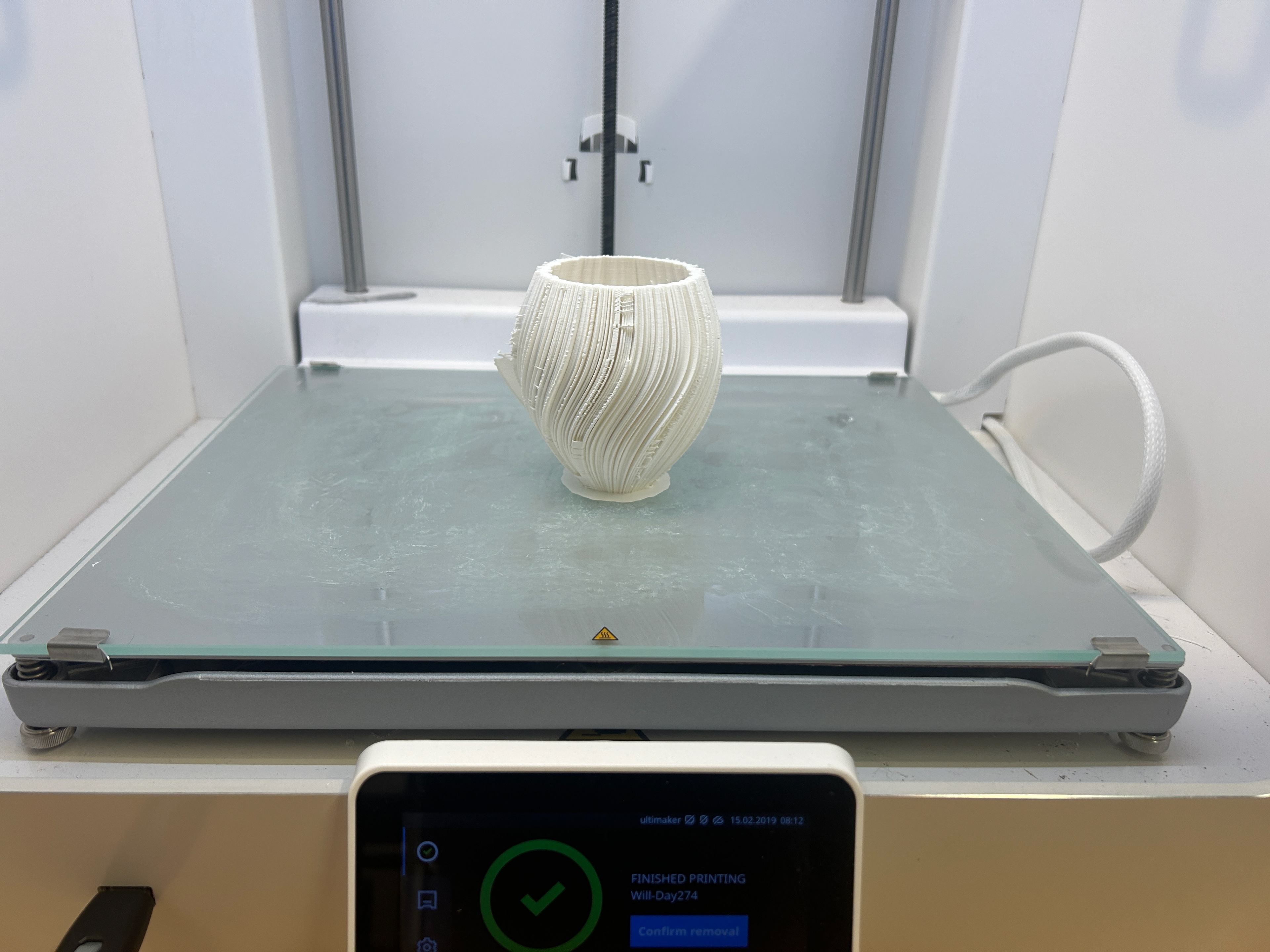

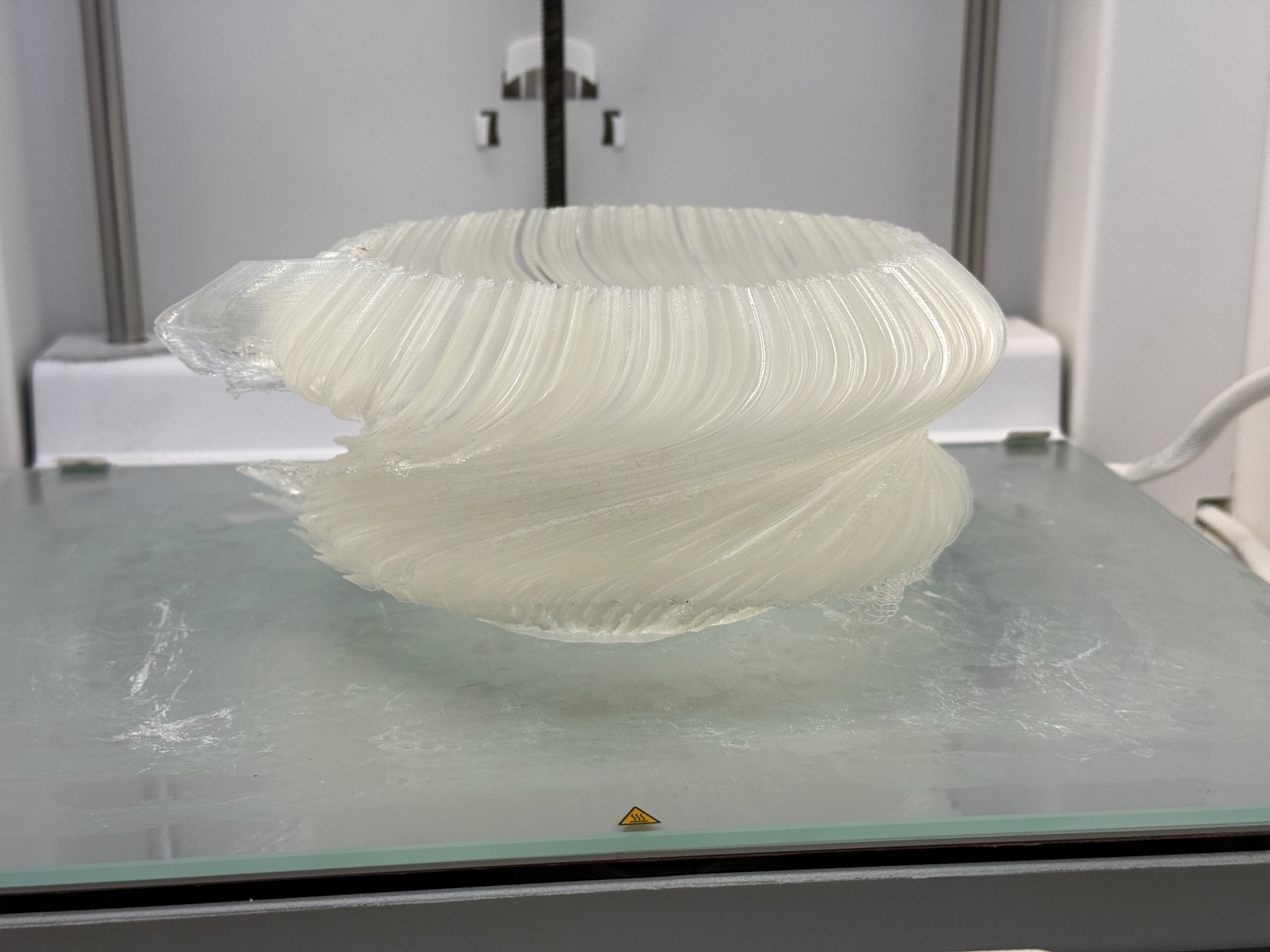

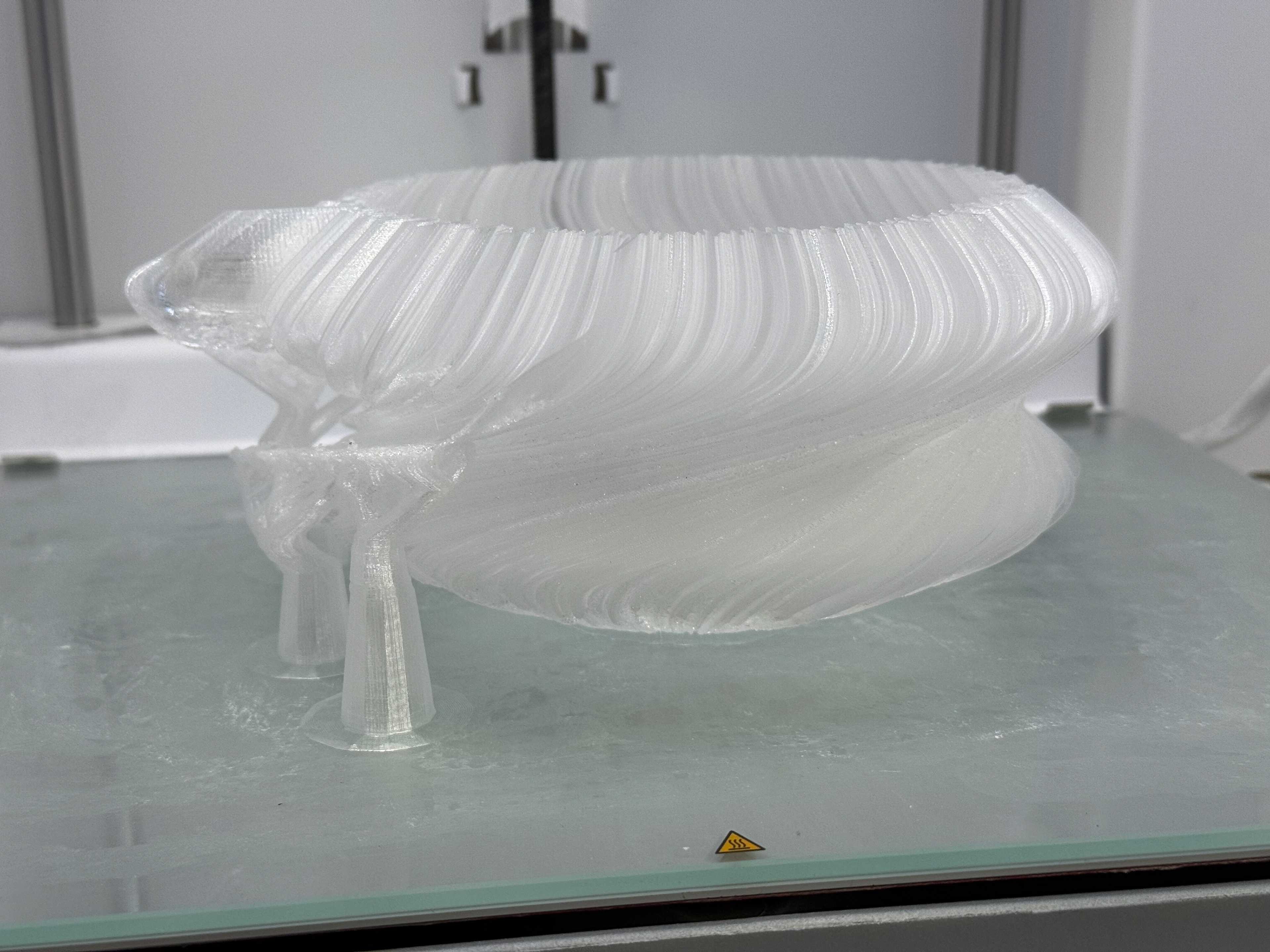

Successful print

Waiting for the bed to cool, lighting looks good.

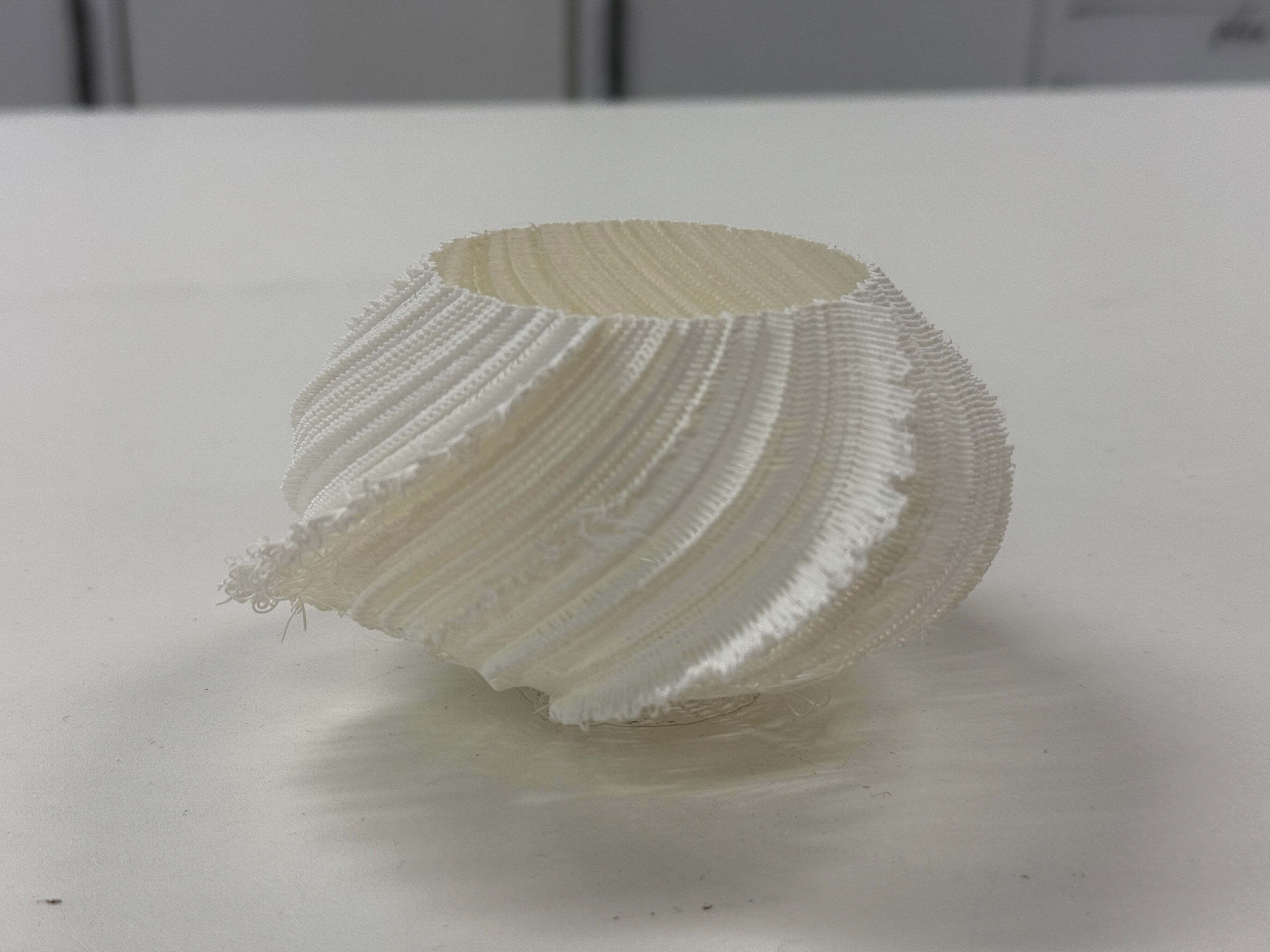

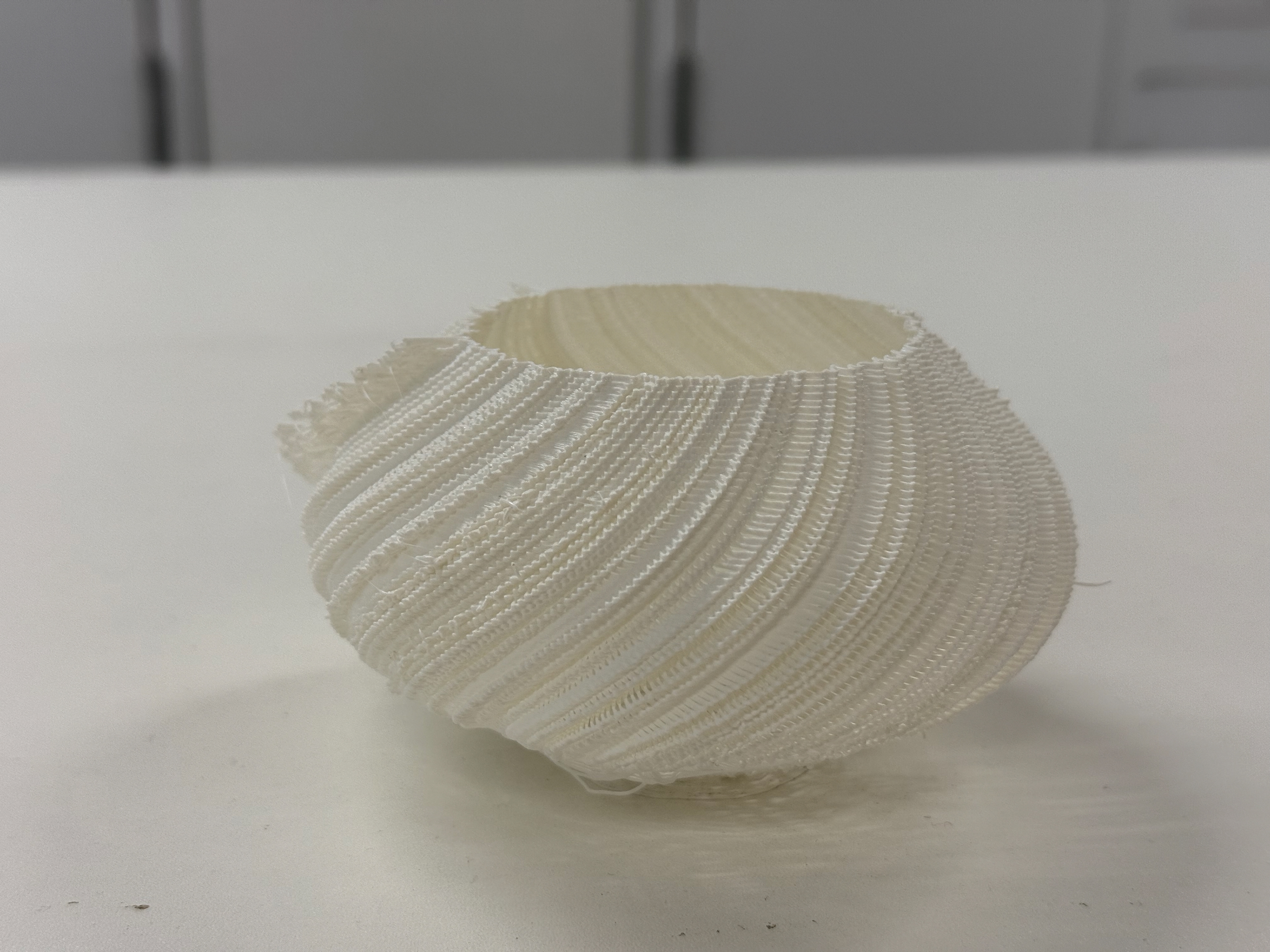

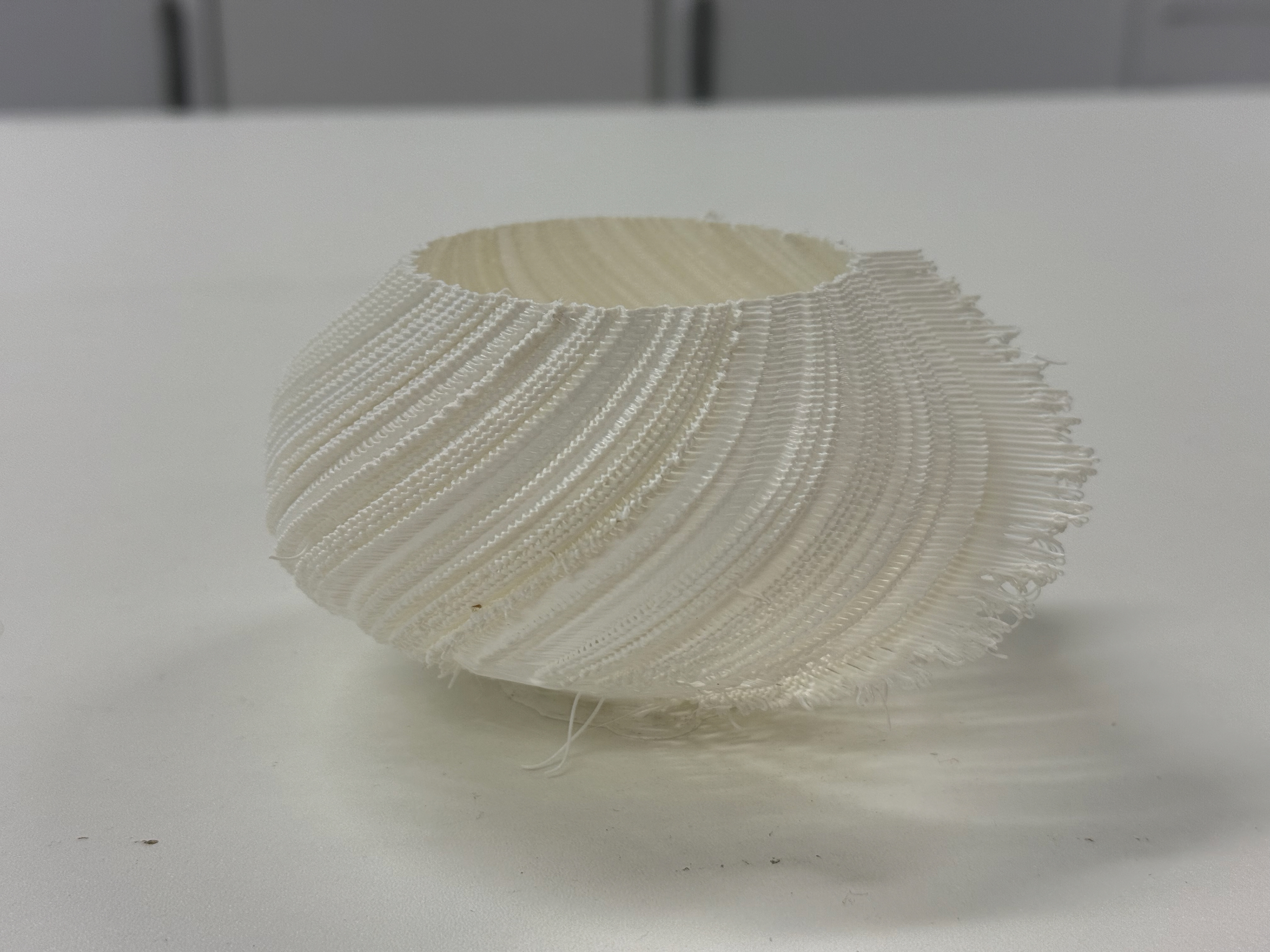

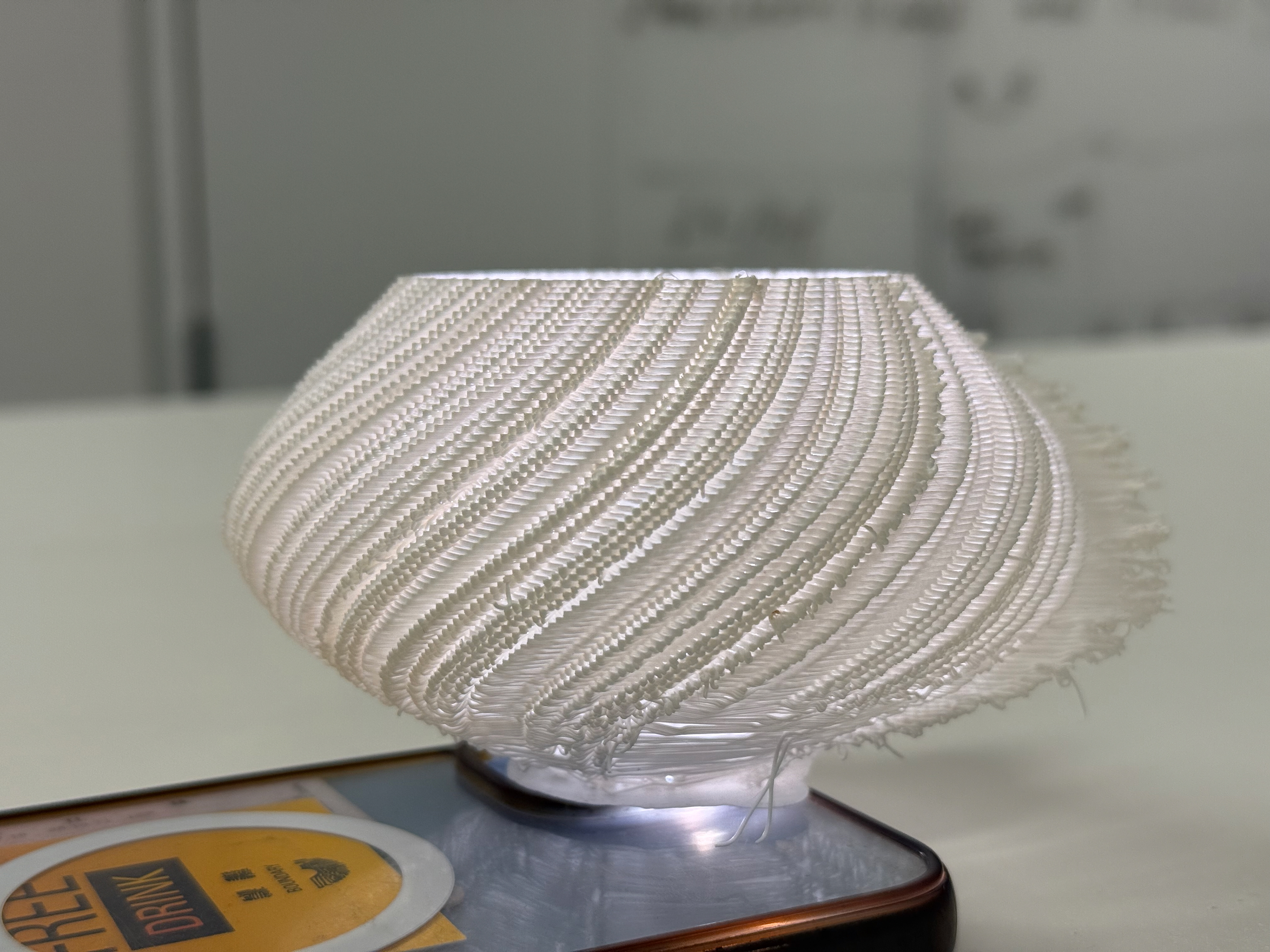

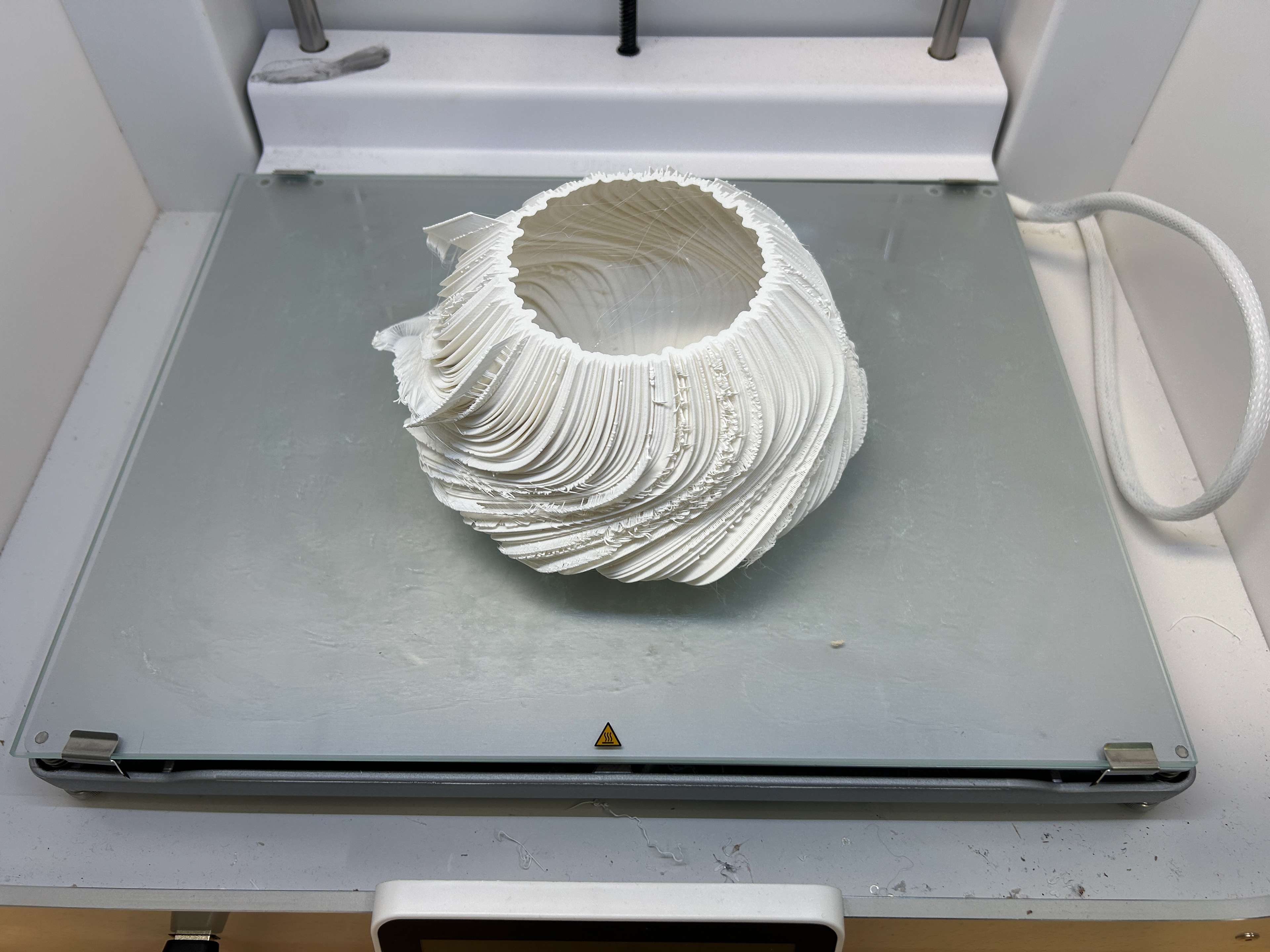

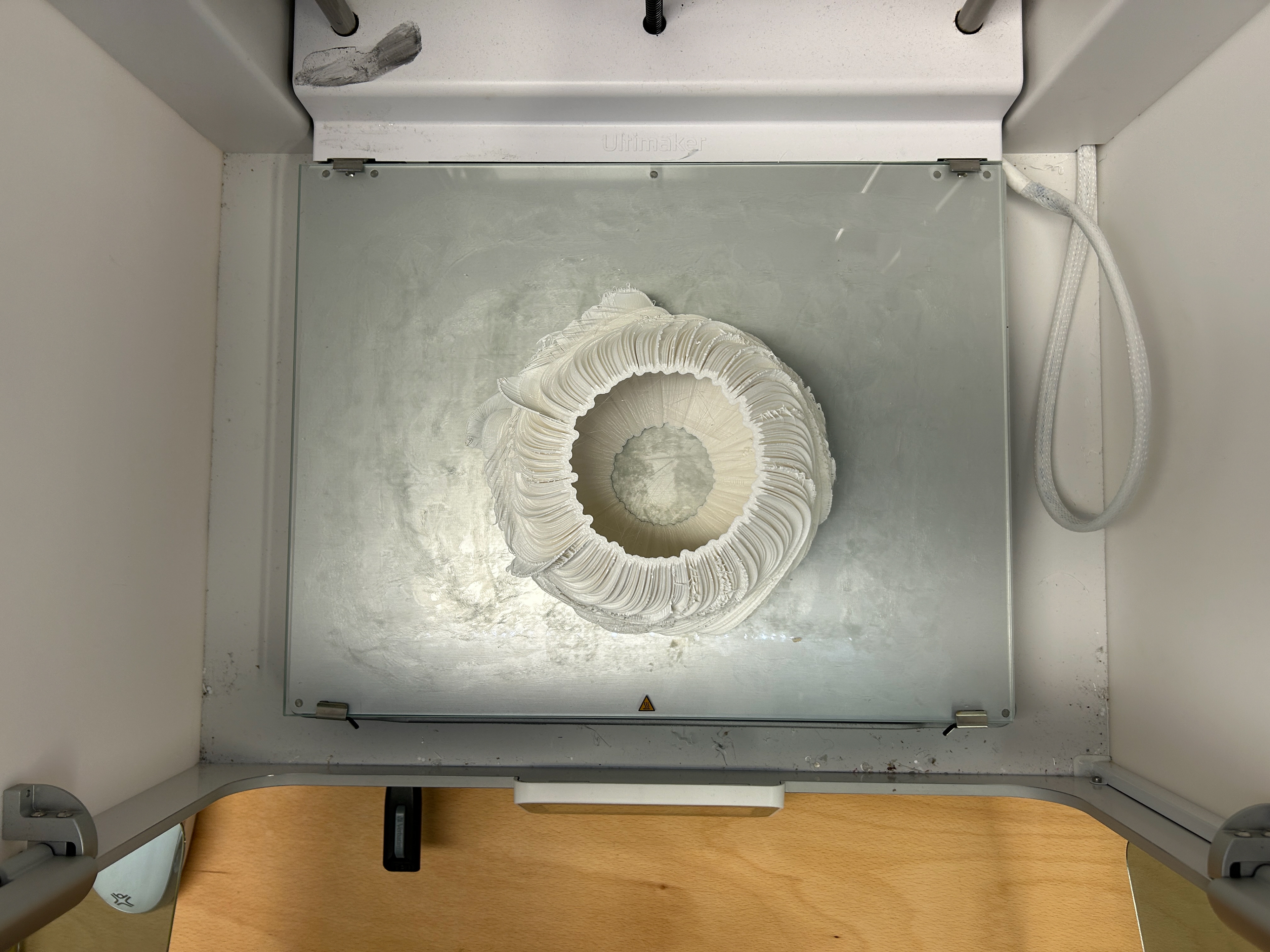

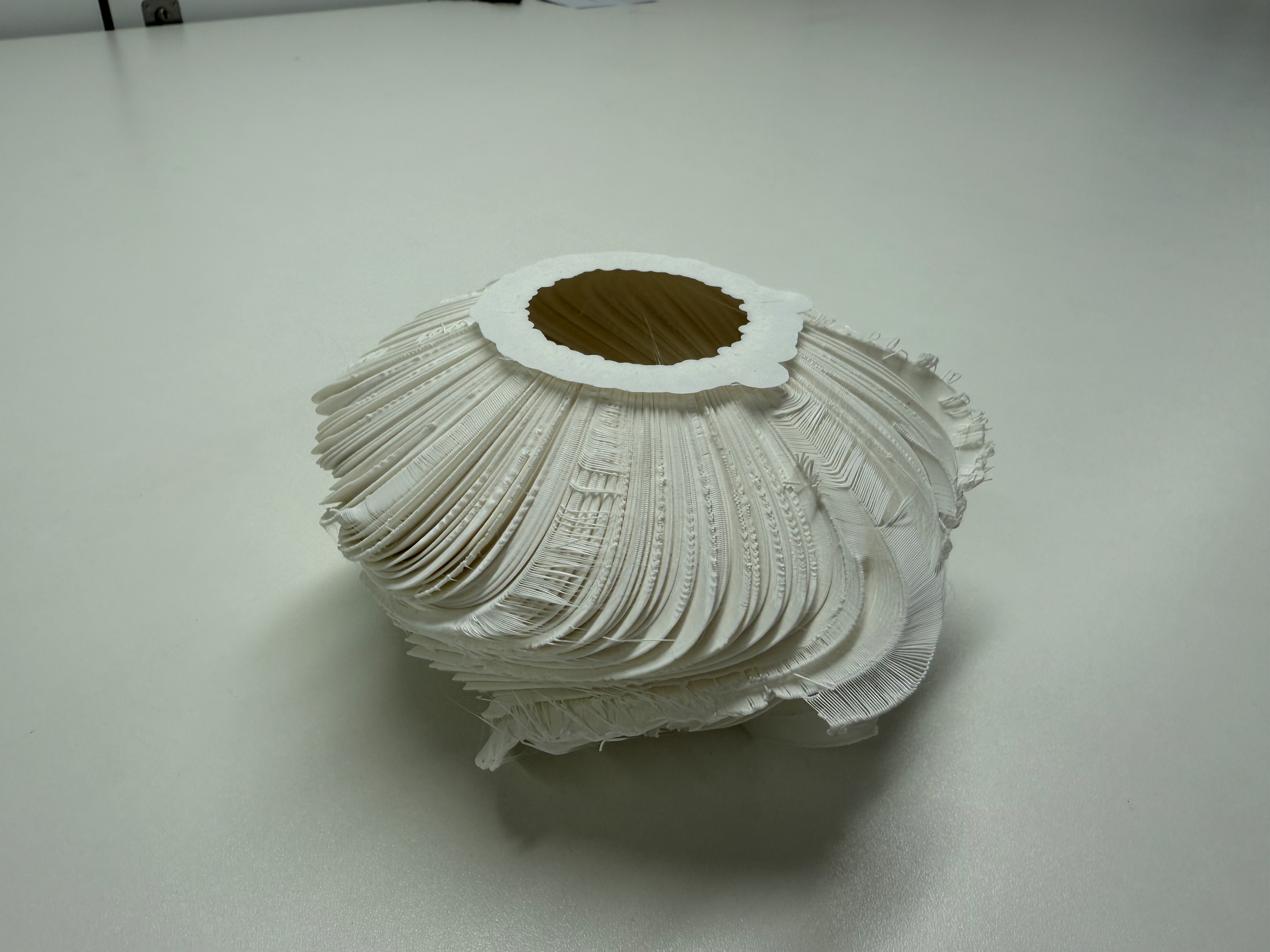

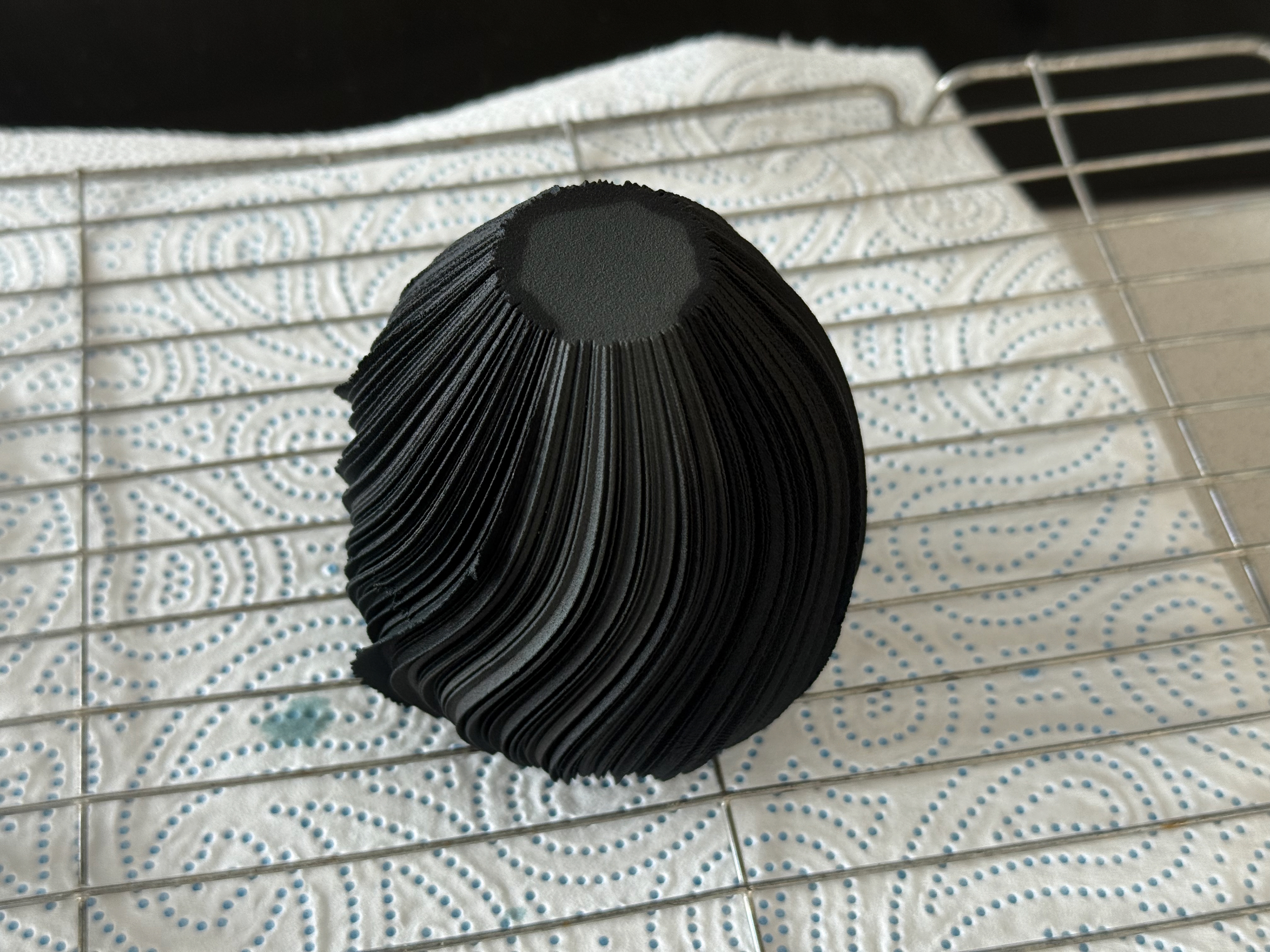

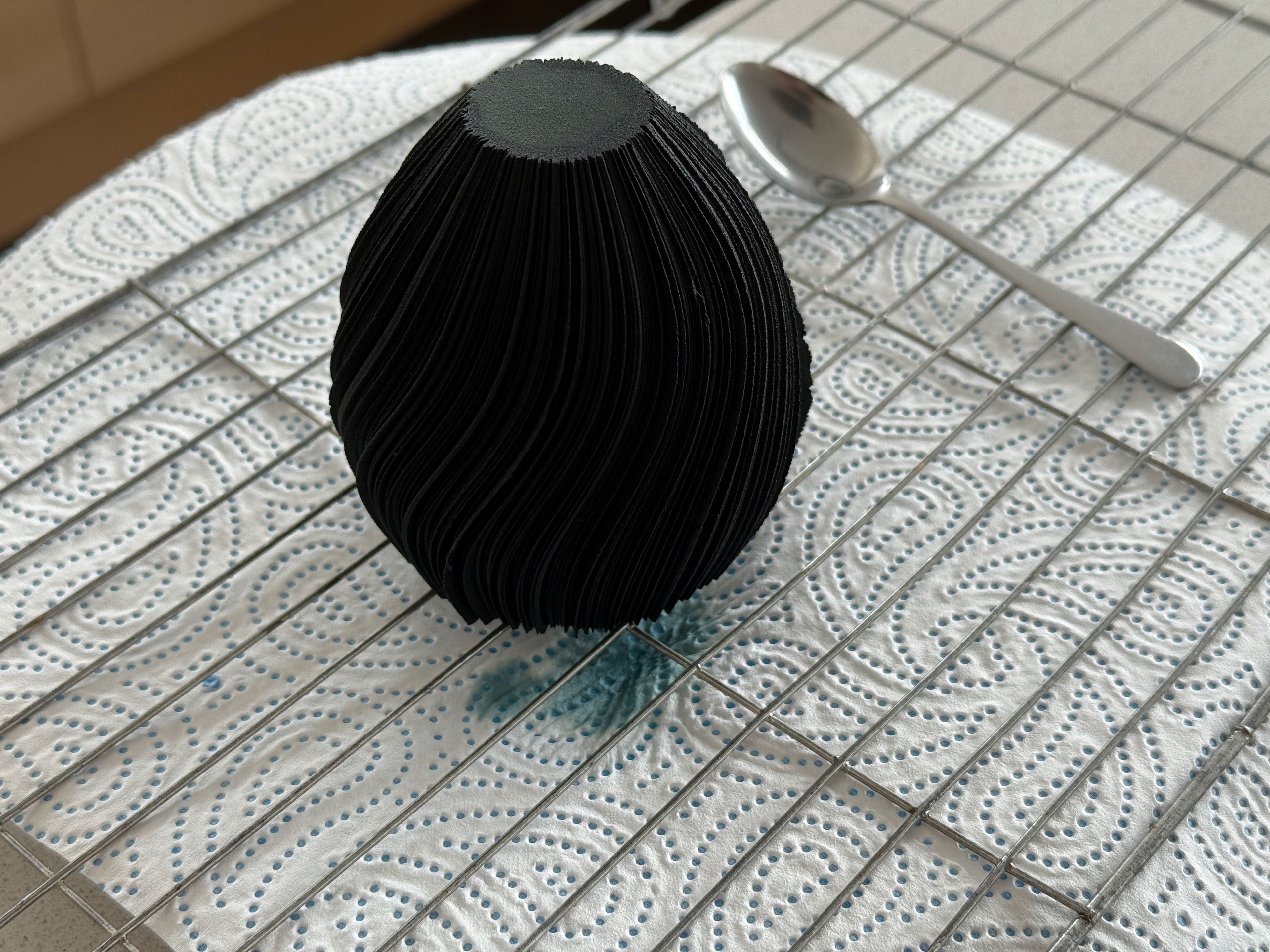

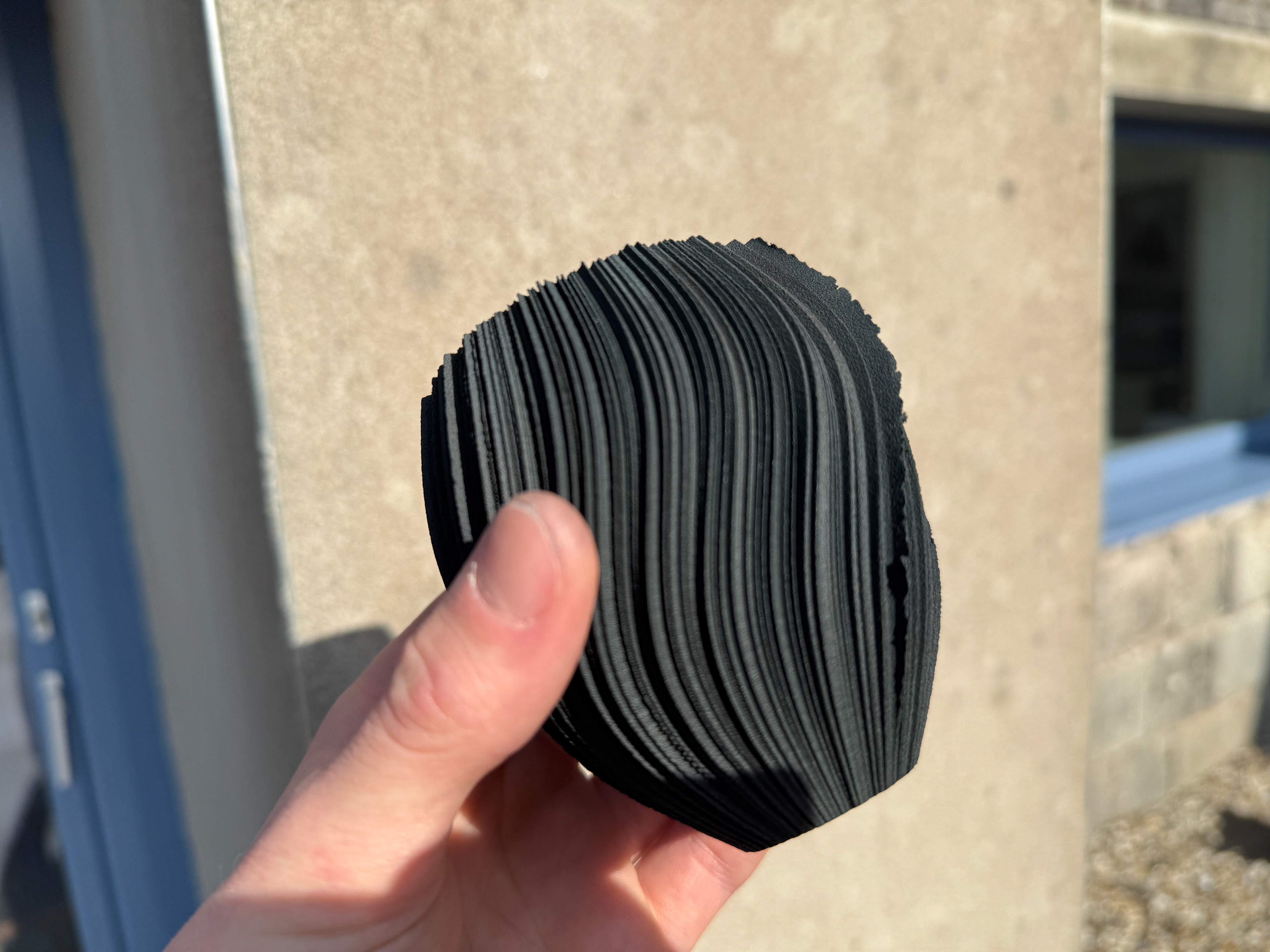

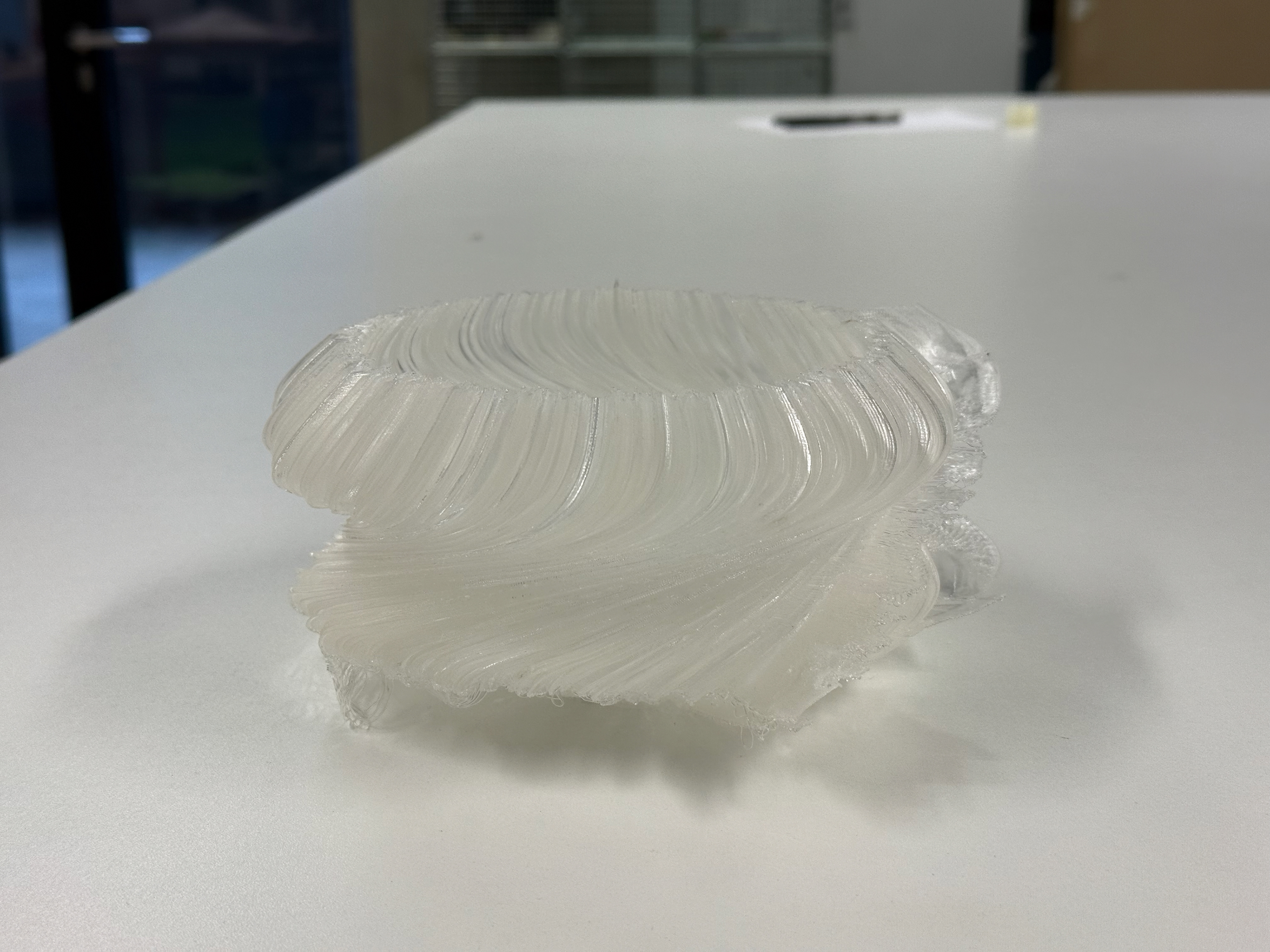

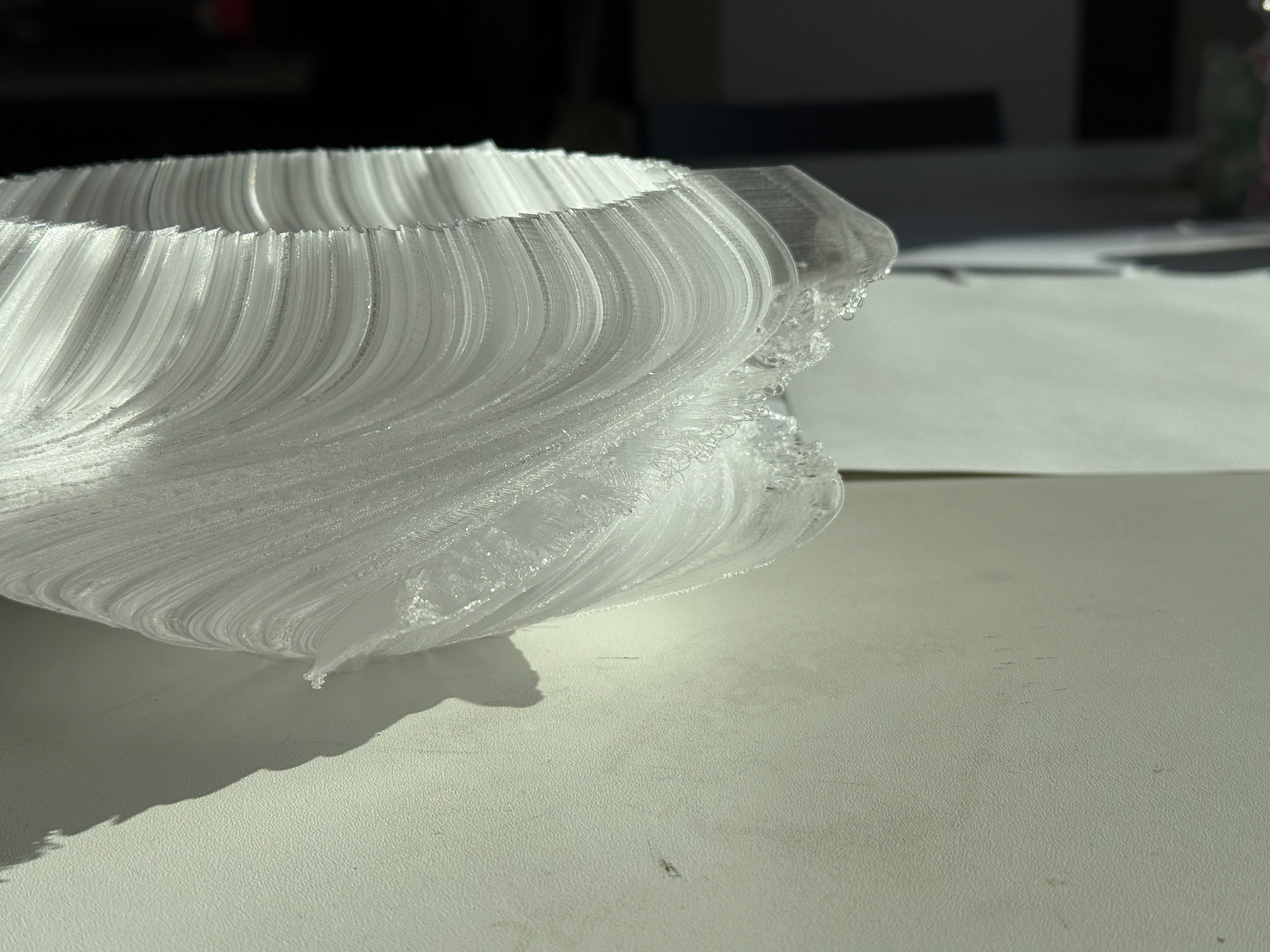

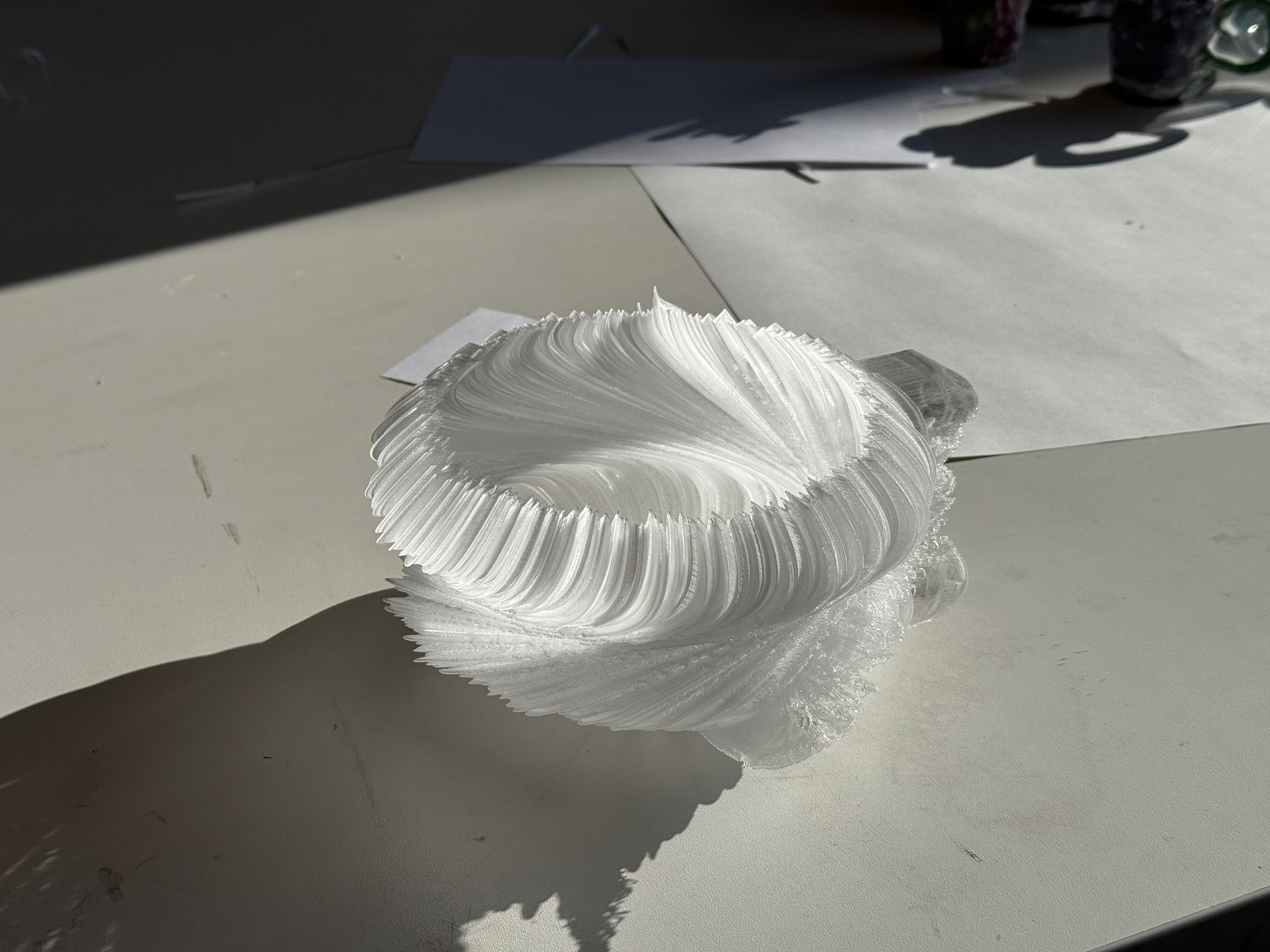

Finished Print

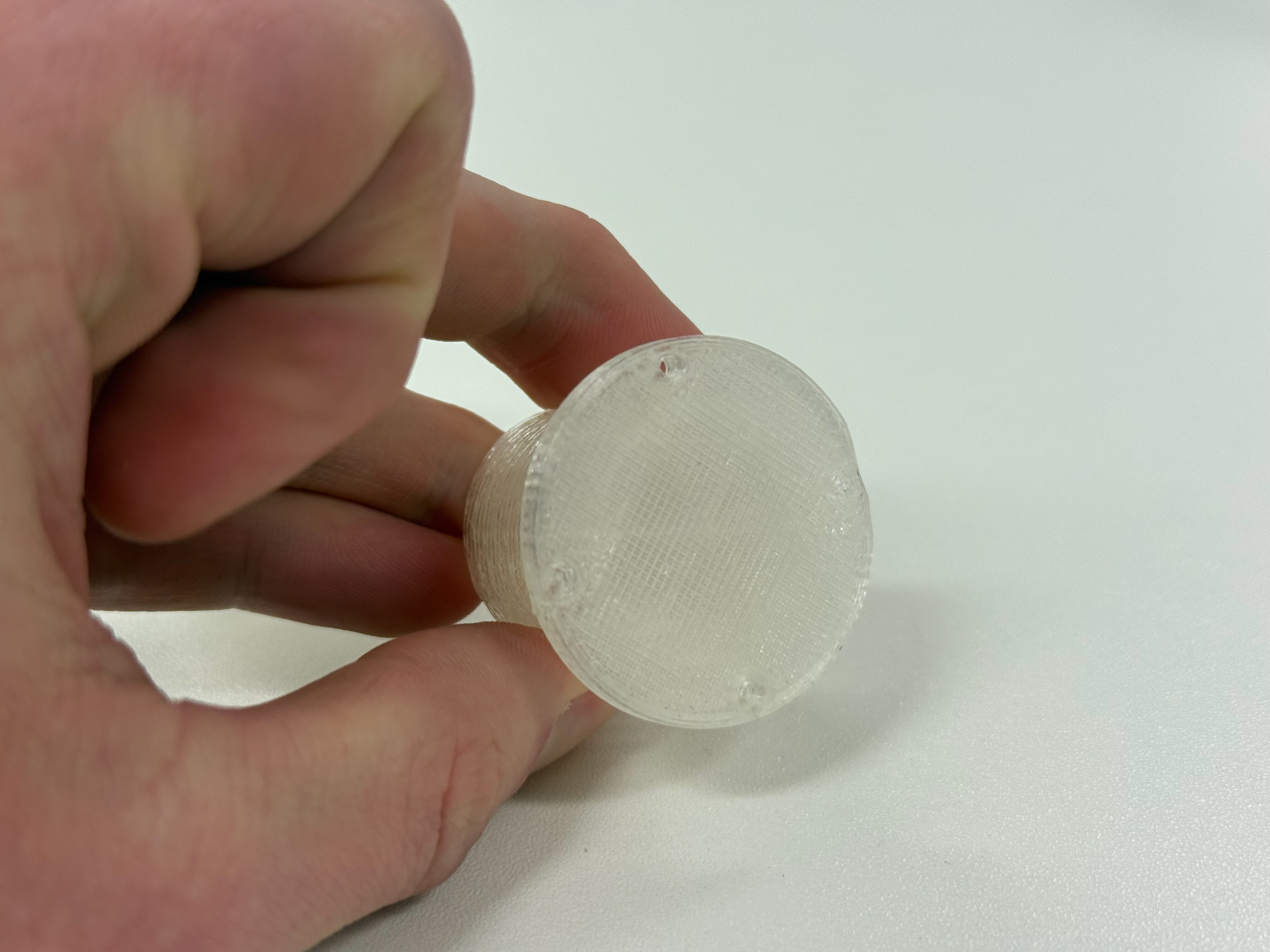

Finished Print

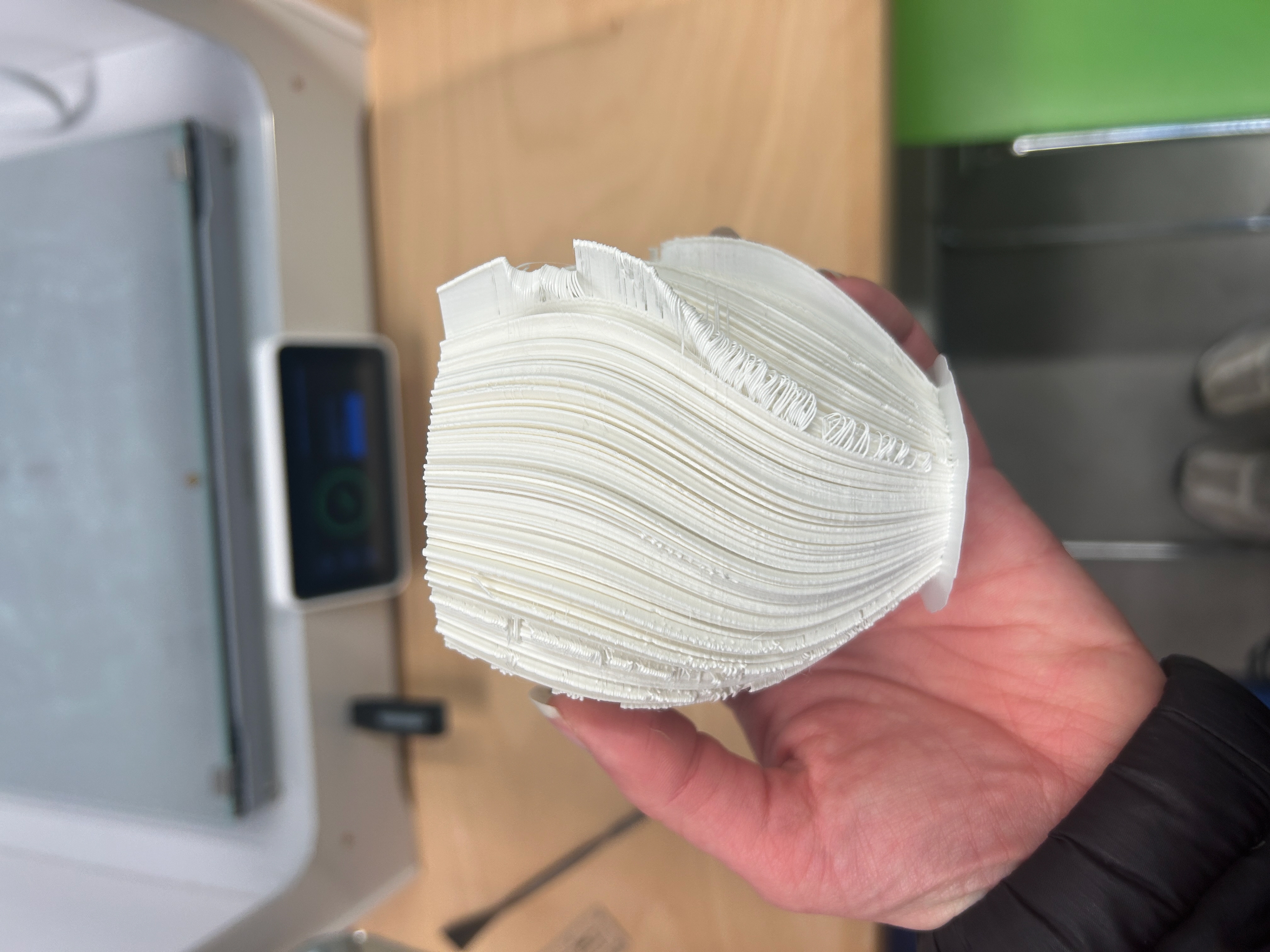

Finished Print

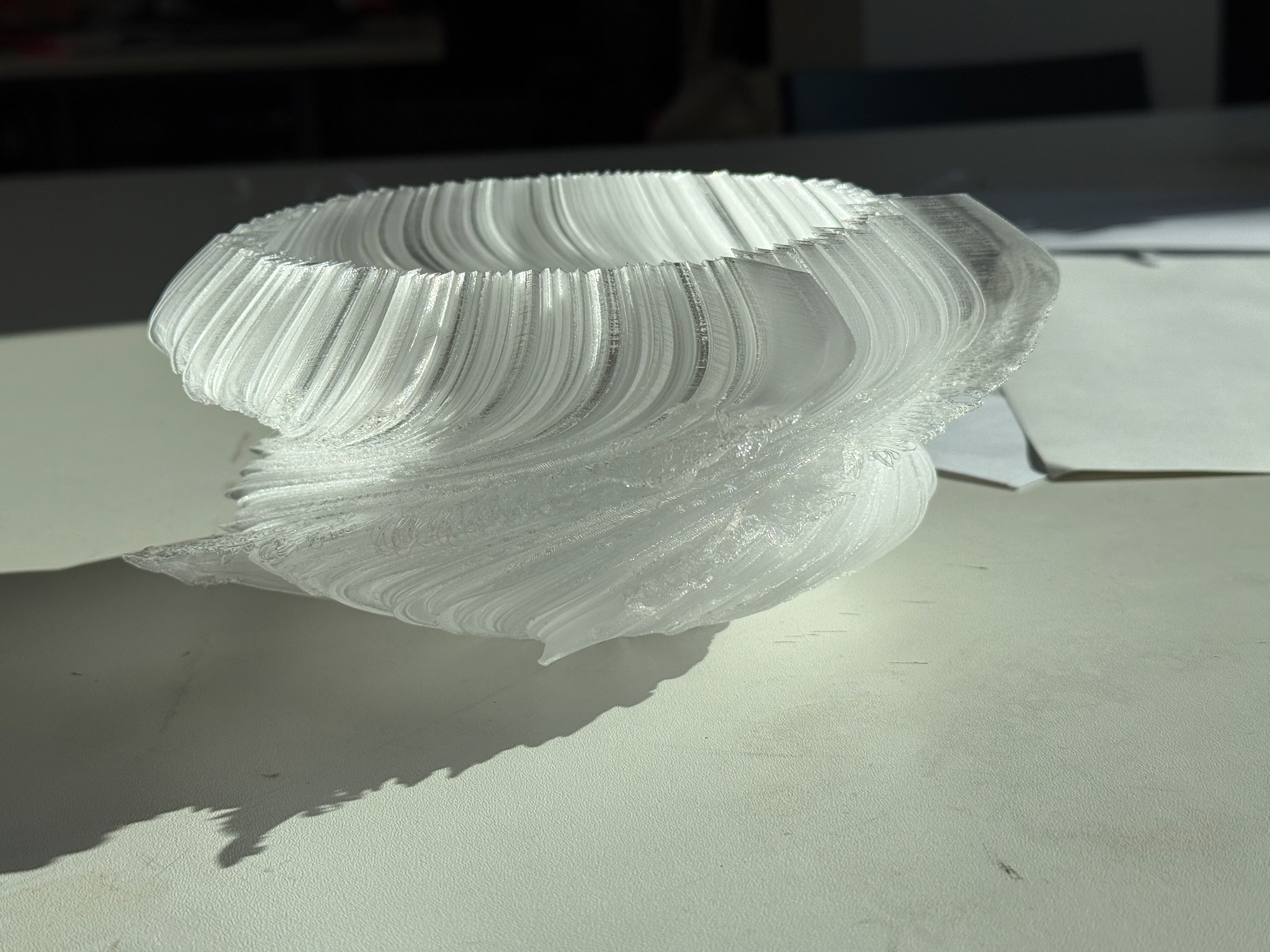

Finished Print

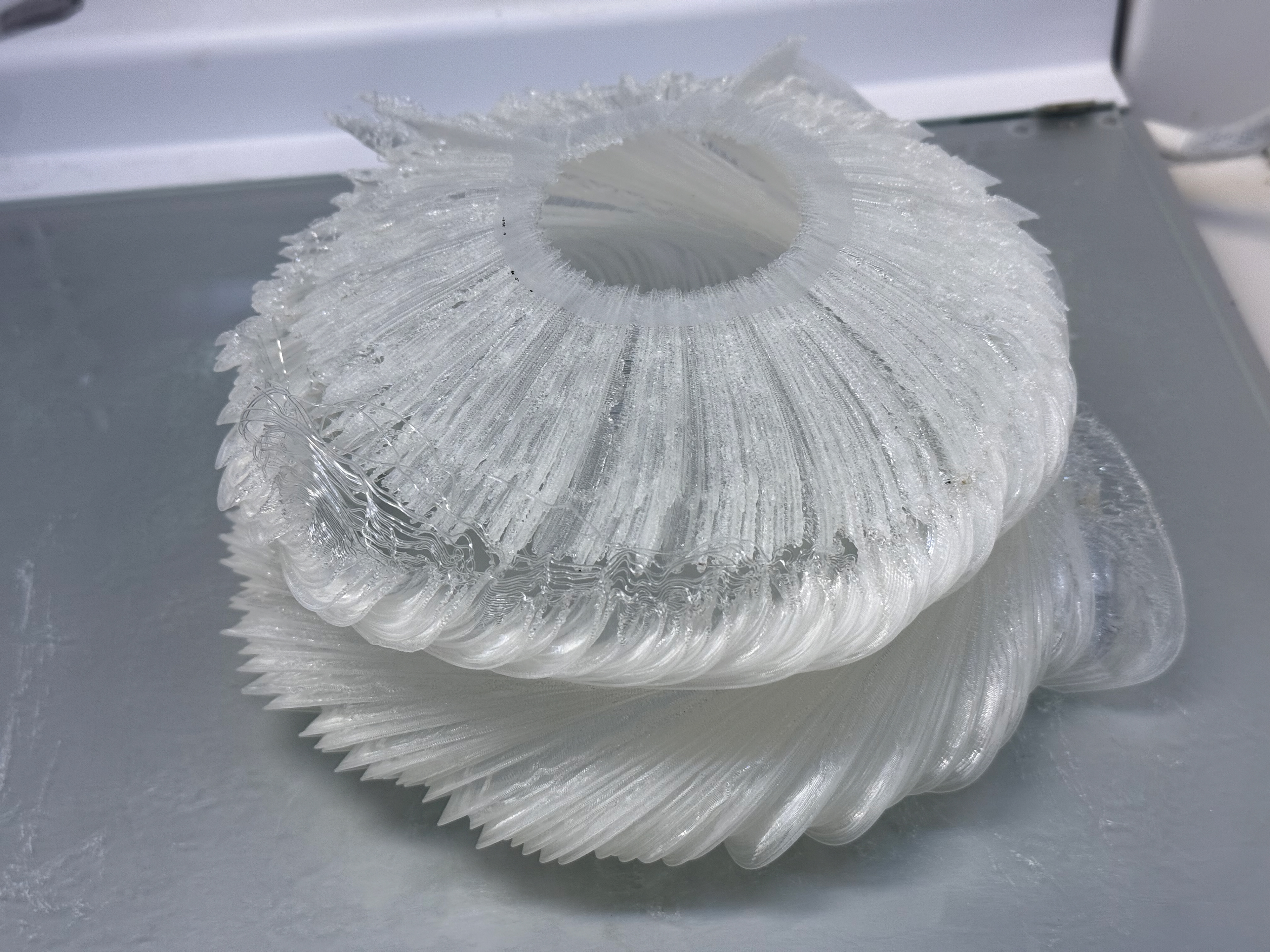

When a light is past through, it looks incredible. the small gaps let light through like a lamp shade

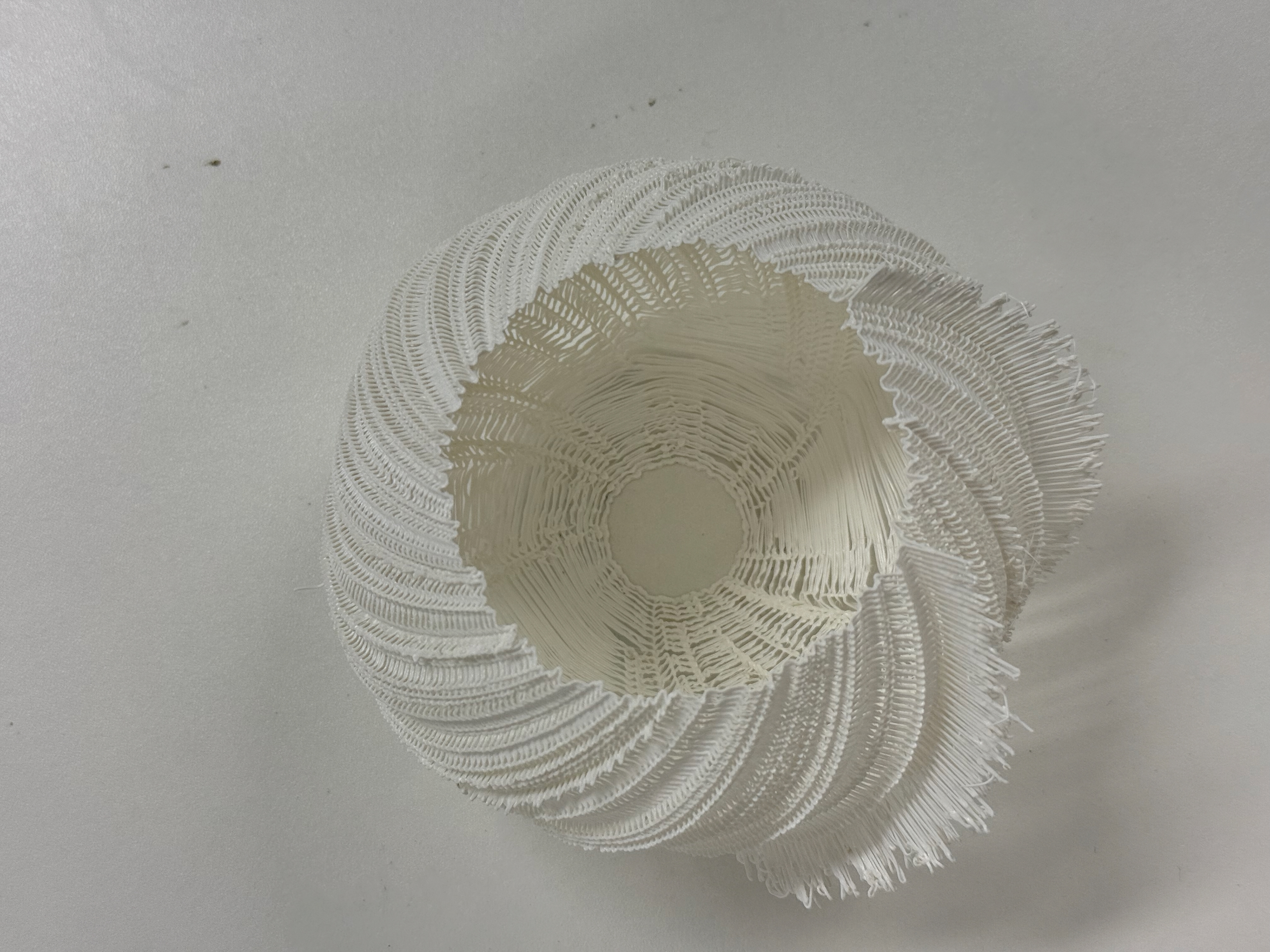

Top view with light

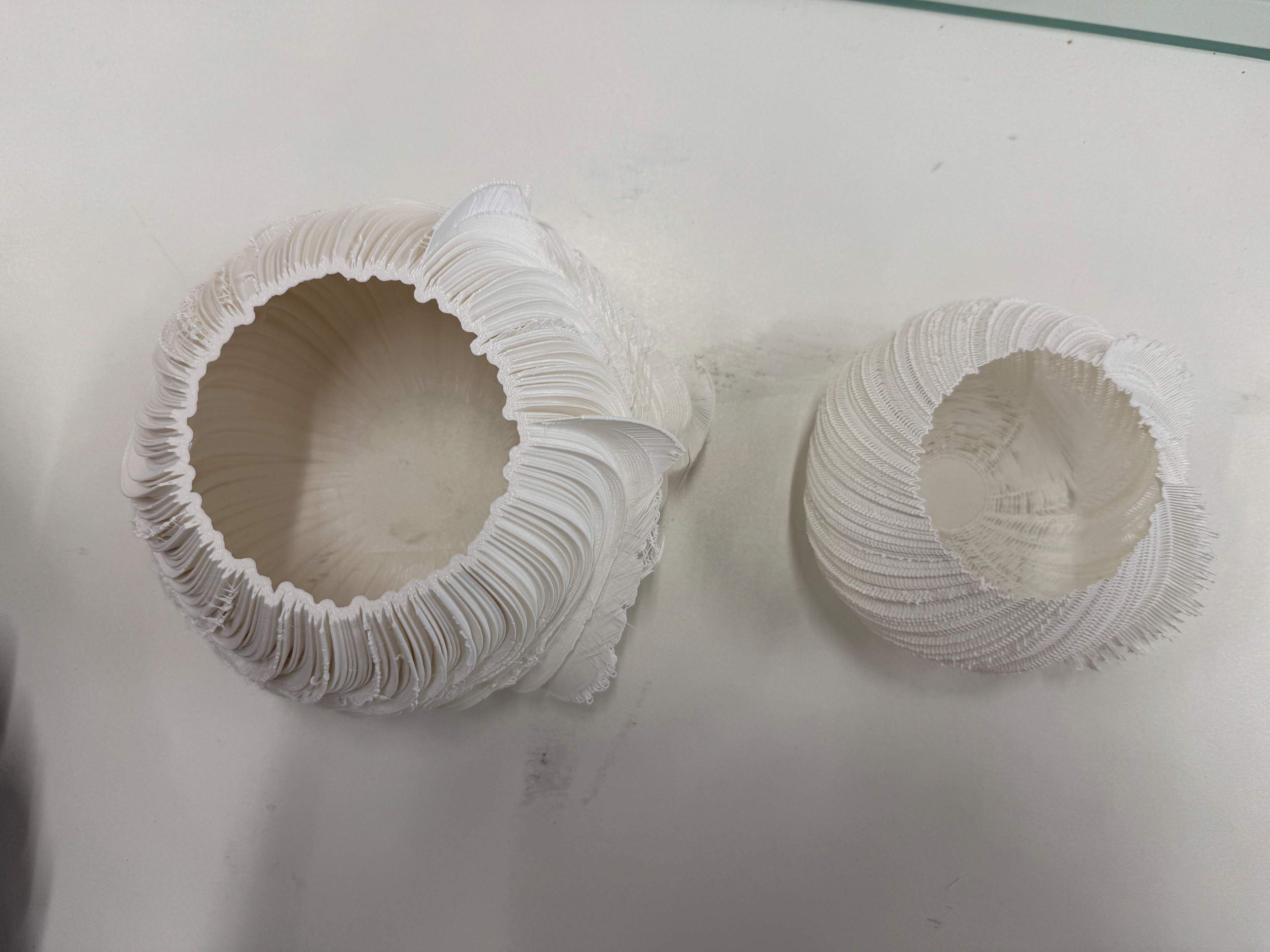

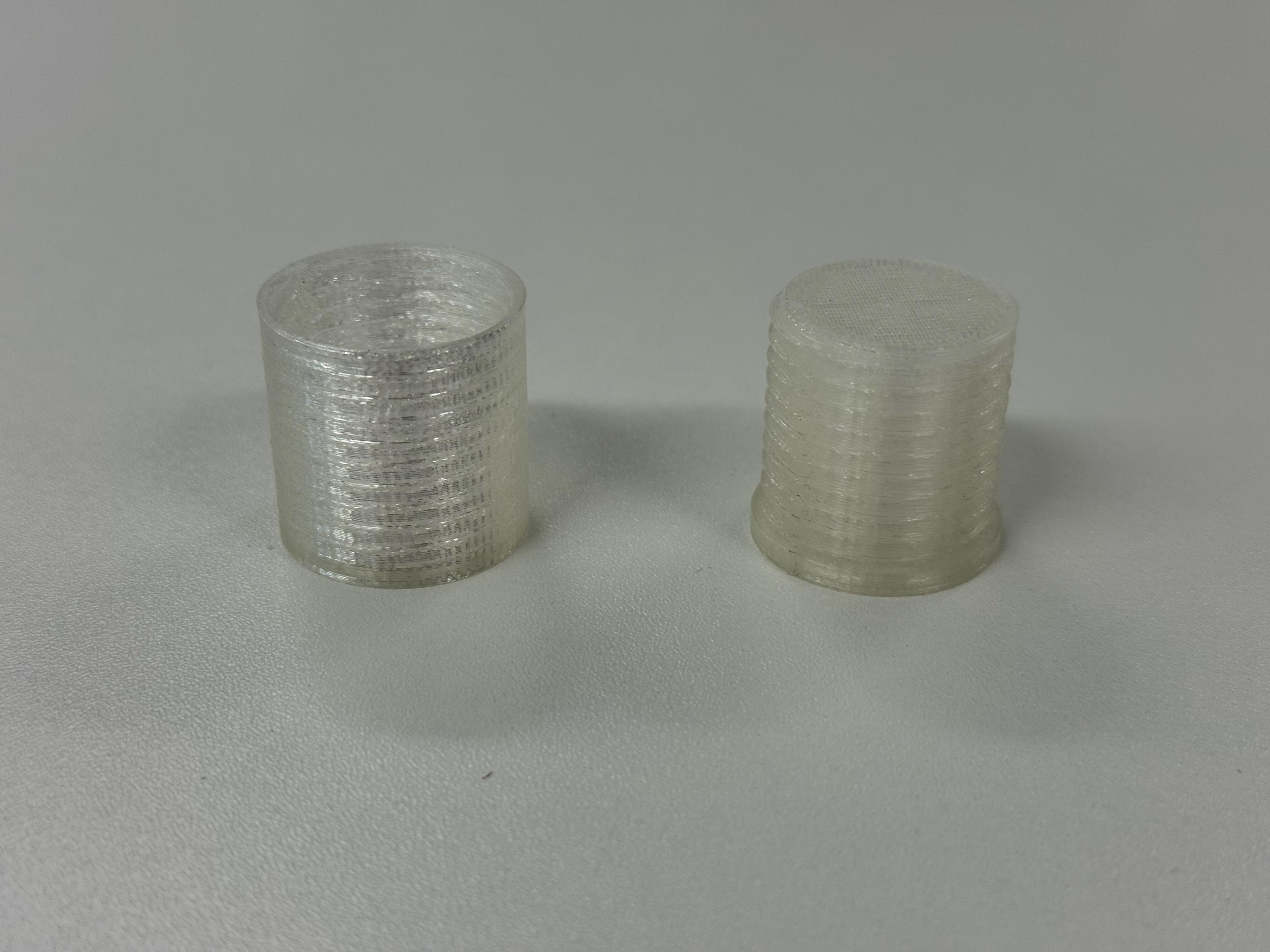

Comparison to Beta

Version 2

Version 3

Version 4

Version 5

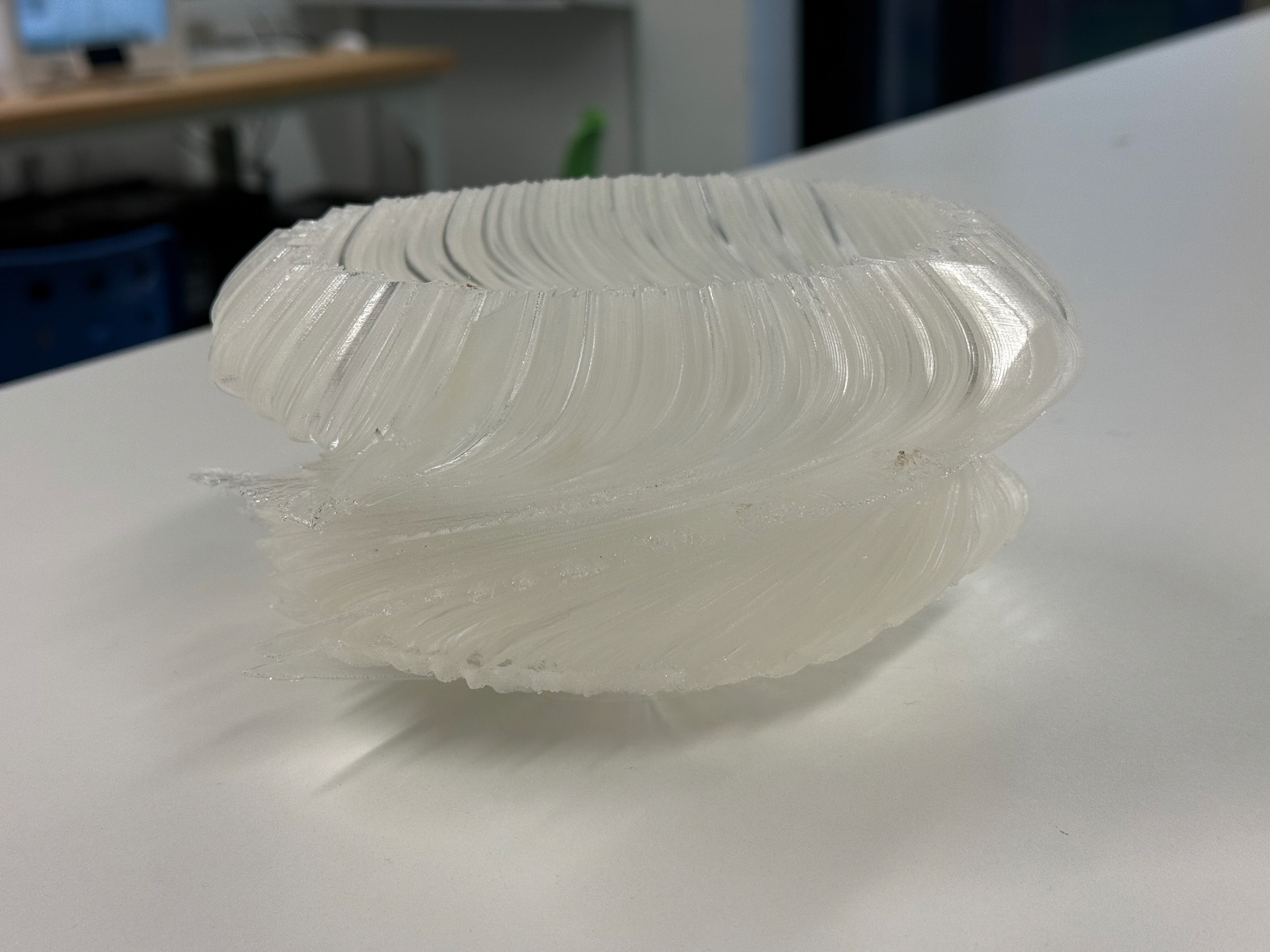

The print started out fine with no issues. Except for Version 1, which I monitored and it looked like I recovered.

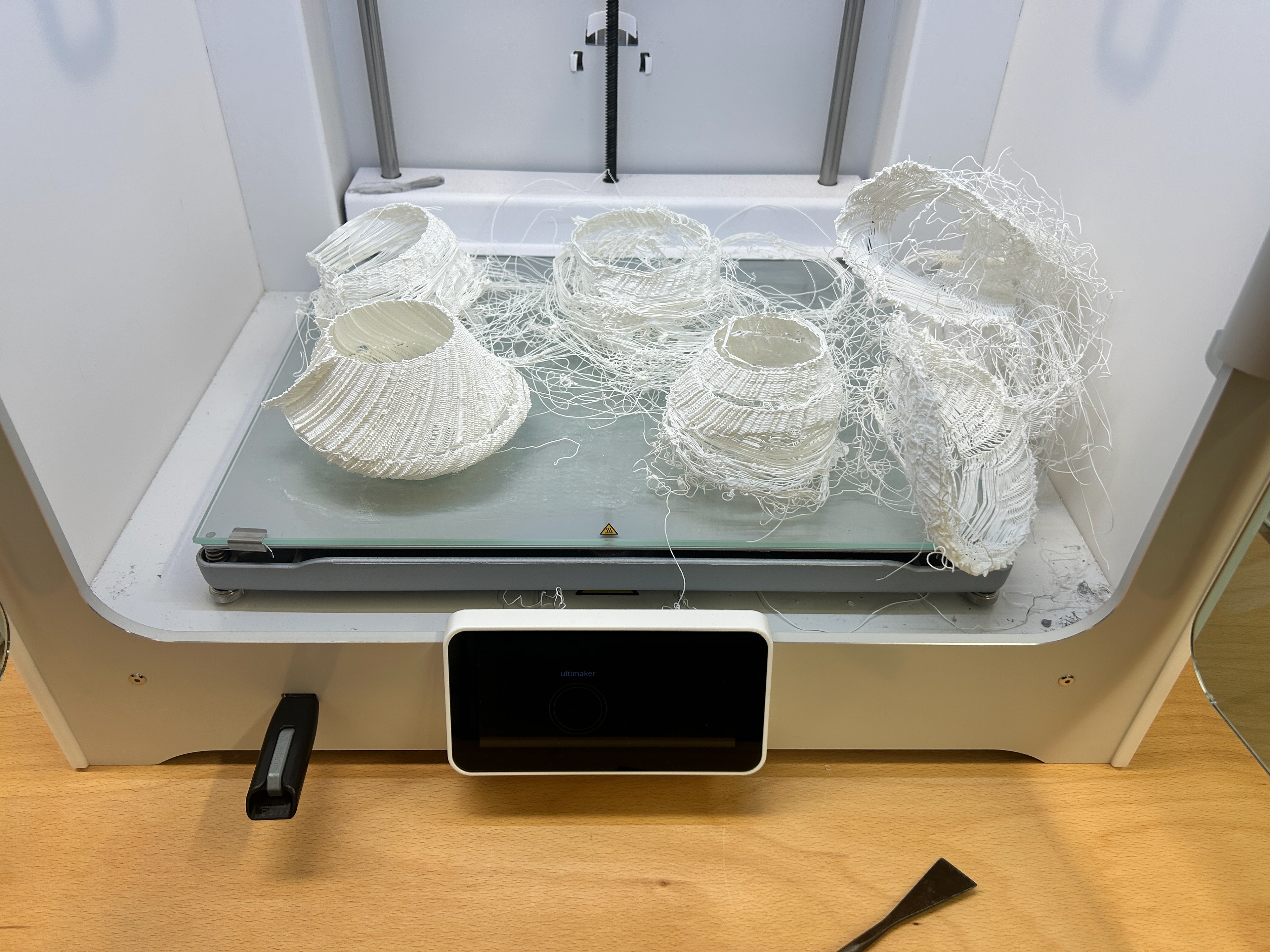

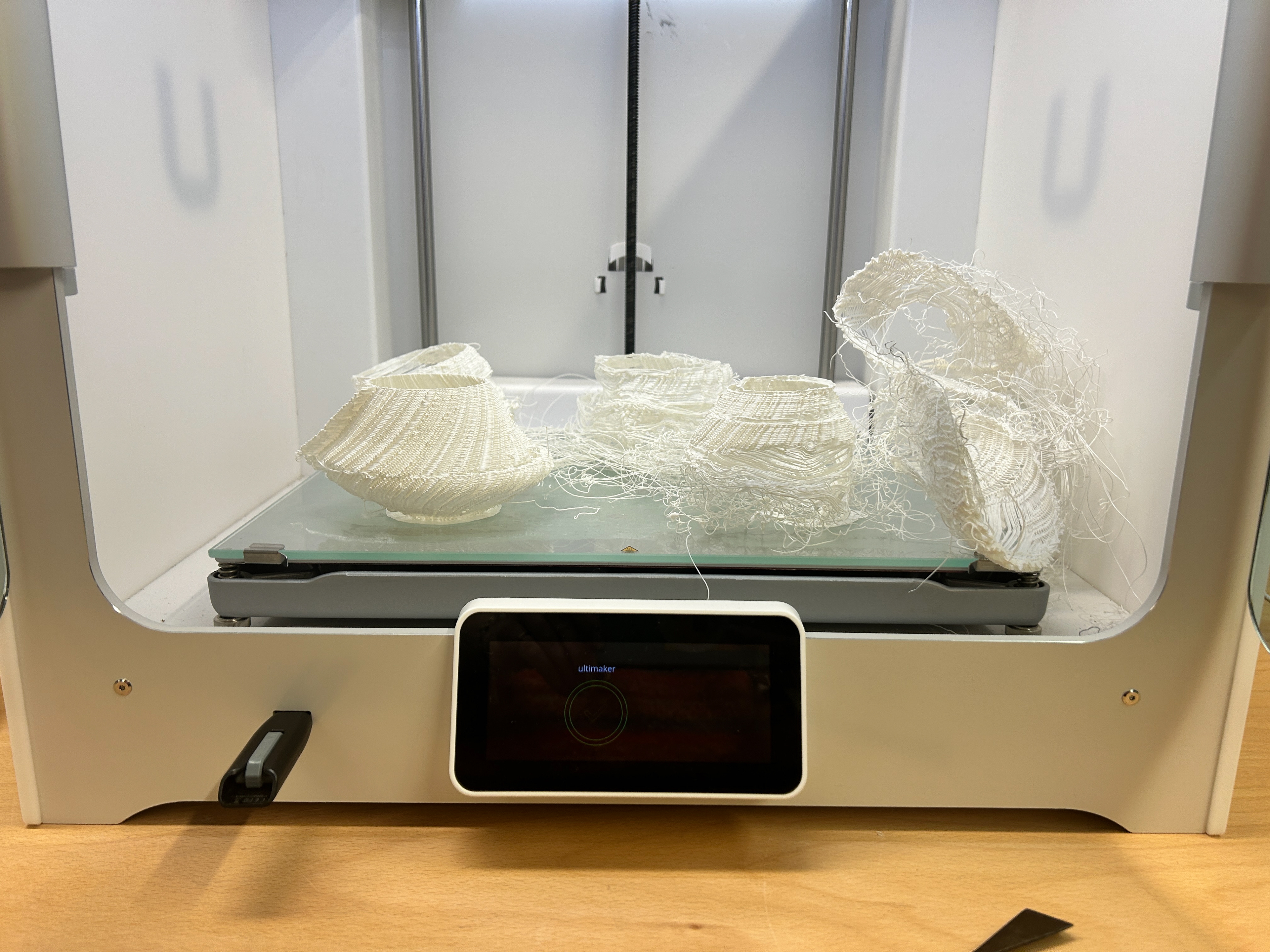

Something catastrophic went wrong through the night

Version 3 was the only salvageable piece.

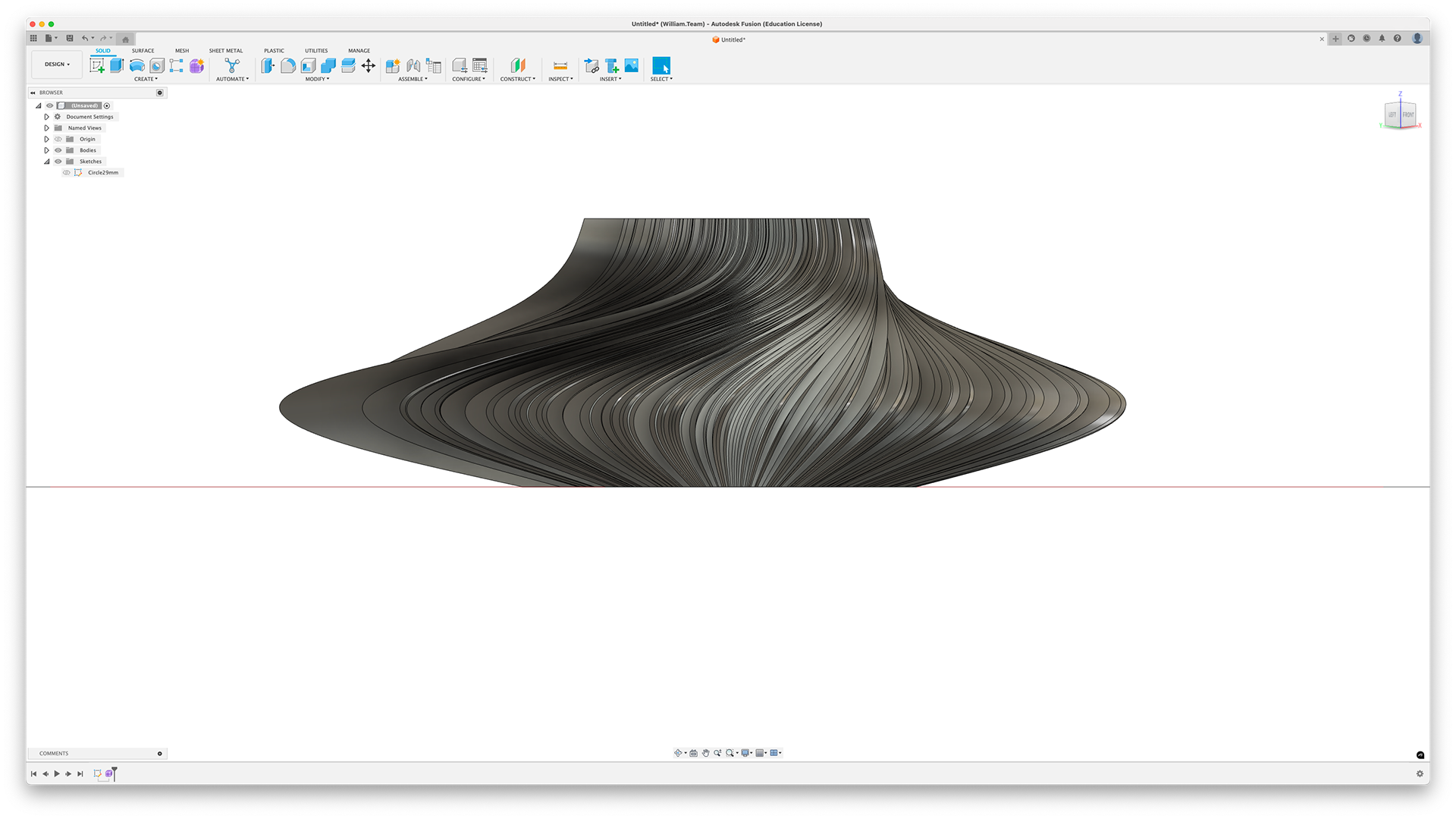

Import .dxf

Select extrude

Extrude to the height (Sleep efficiency %) and then set the number of faces to 3

Select the bottom face and scale up according to the numbers document

Select the lower middle face and scale up according to the numbers document

Select the upper middle face and scale up according to the numbers document

Select the top face and scale up according to the numbers document

Select the top two faces and twist (Sleep performance %)

Select the whole object and fill in, set to "Collapse" and "Keep Creases"

The piece

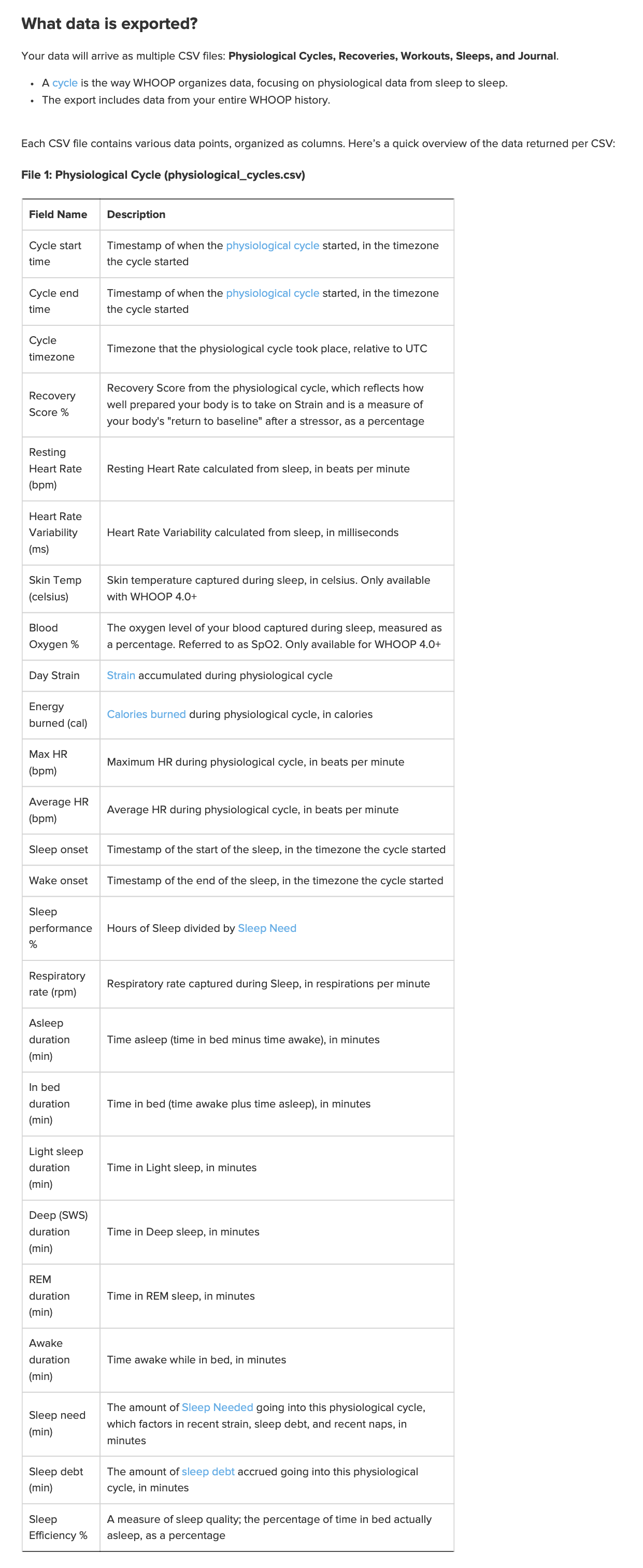

This is not all the data. I have 625 rows in total.

Cura Settings

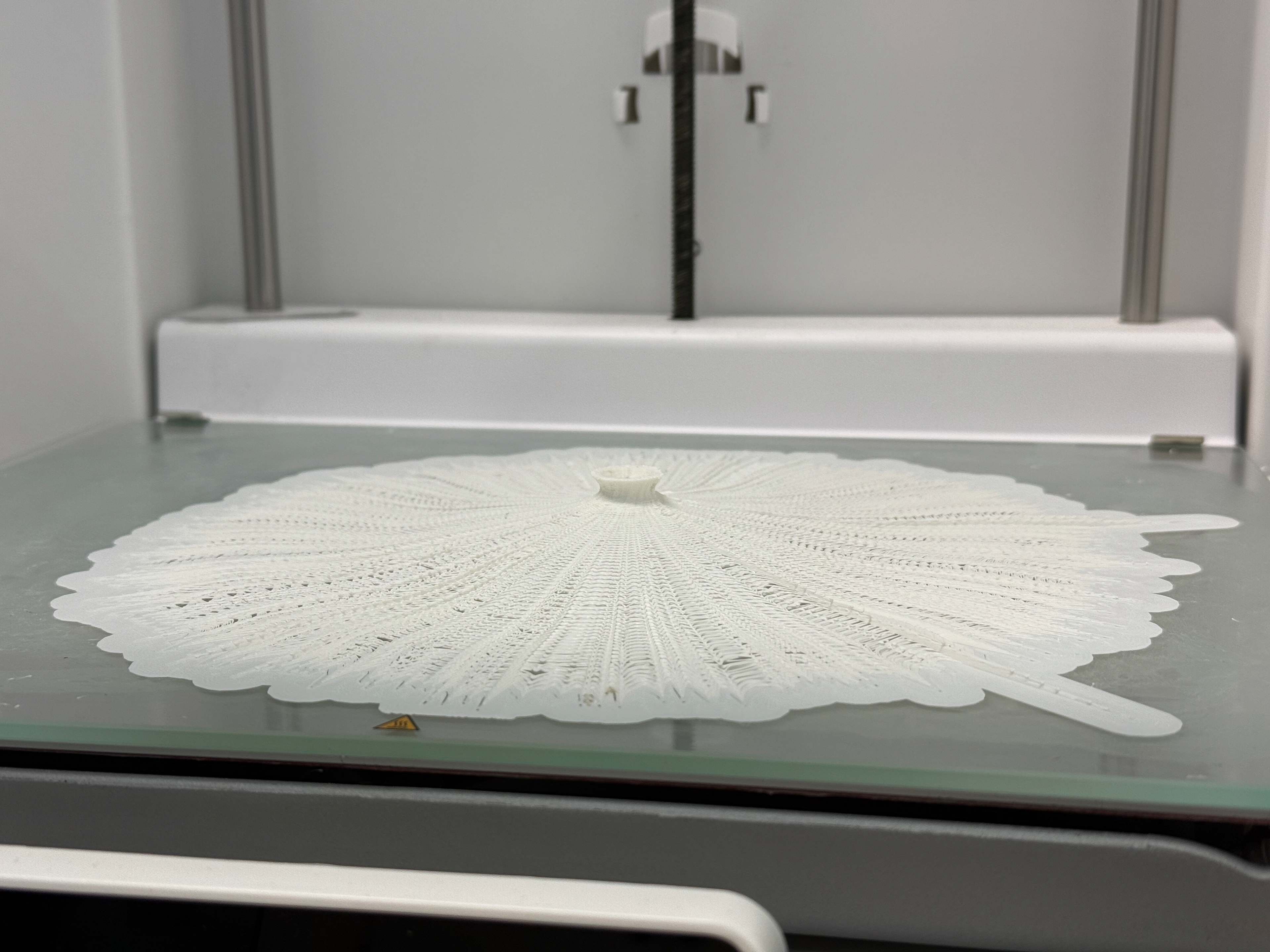

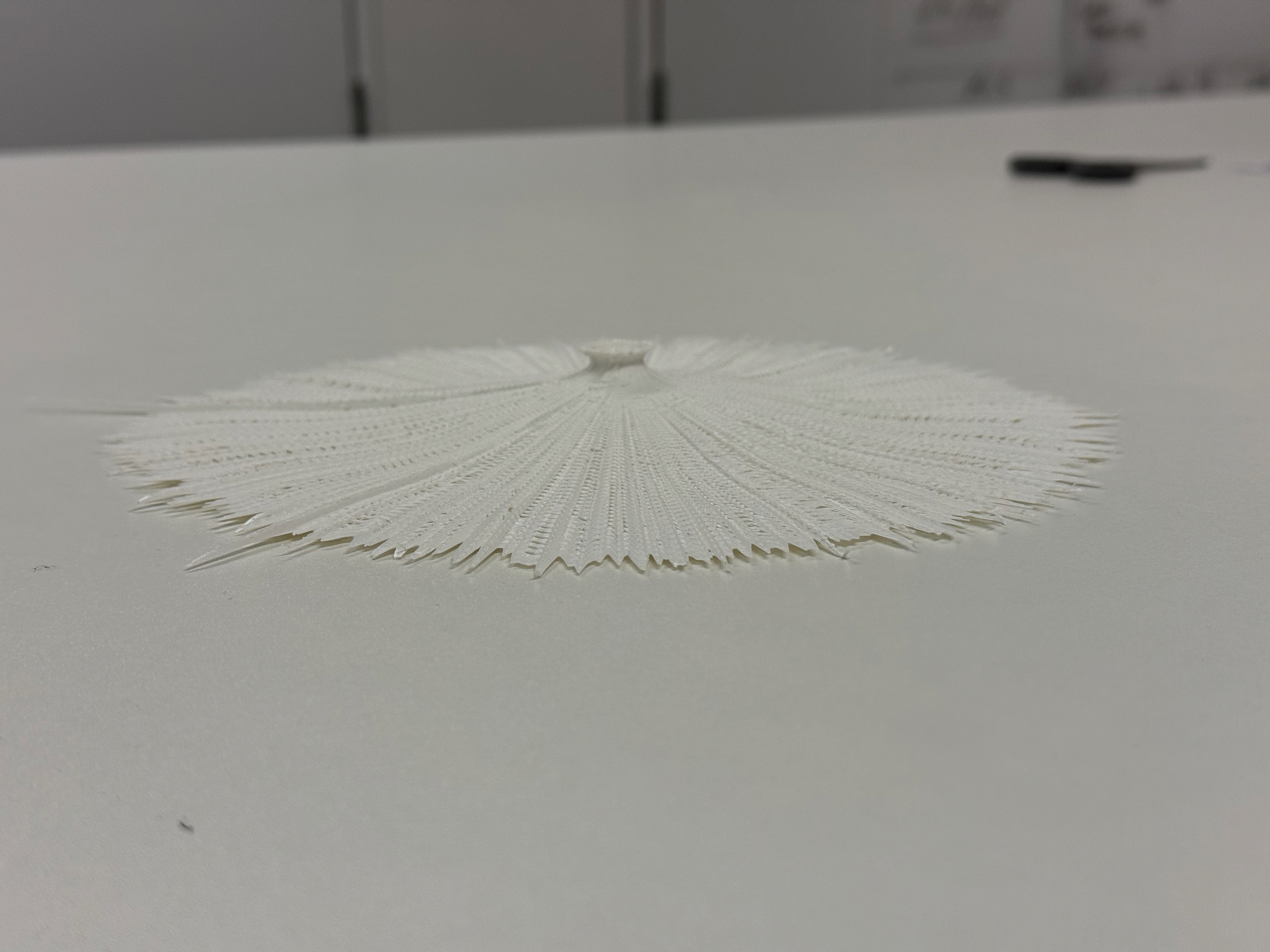

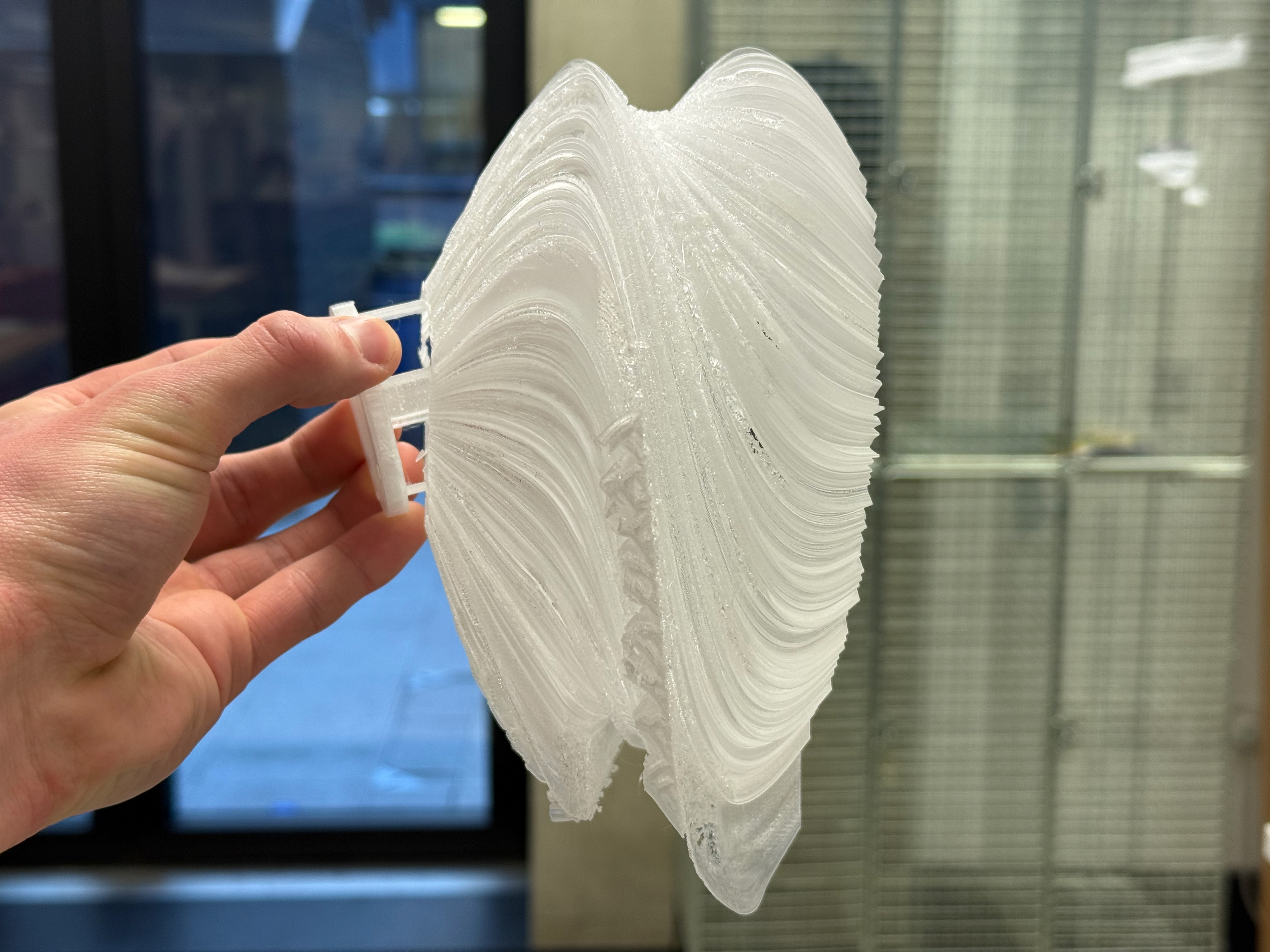

ON the 30cm squared print bed for scale

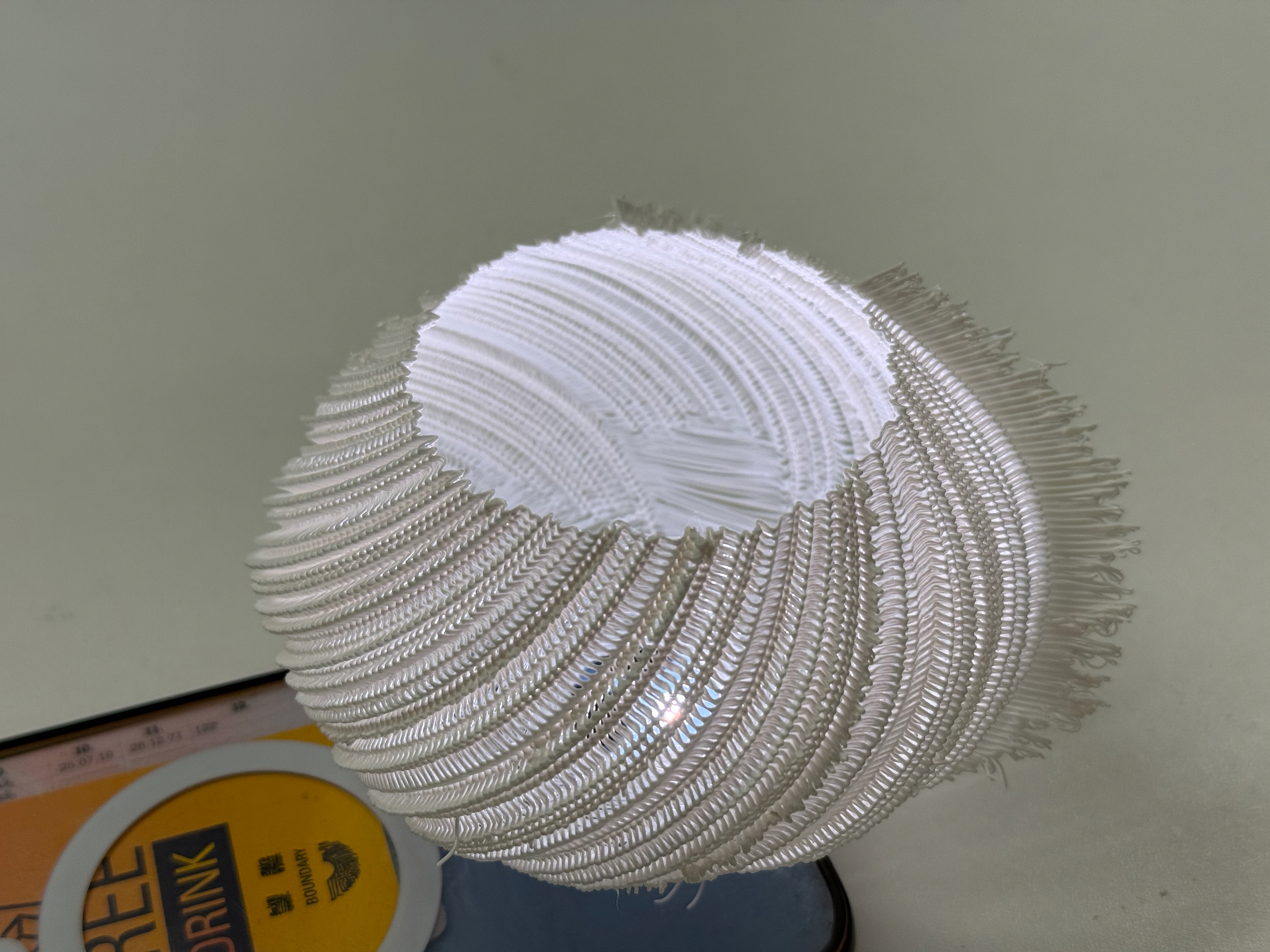

Side upper view

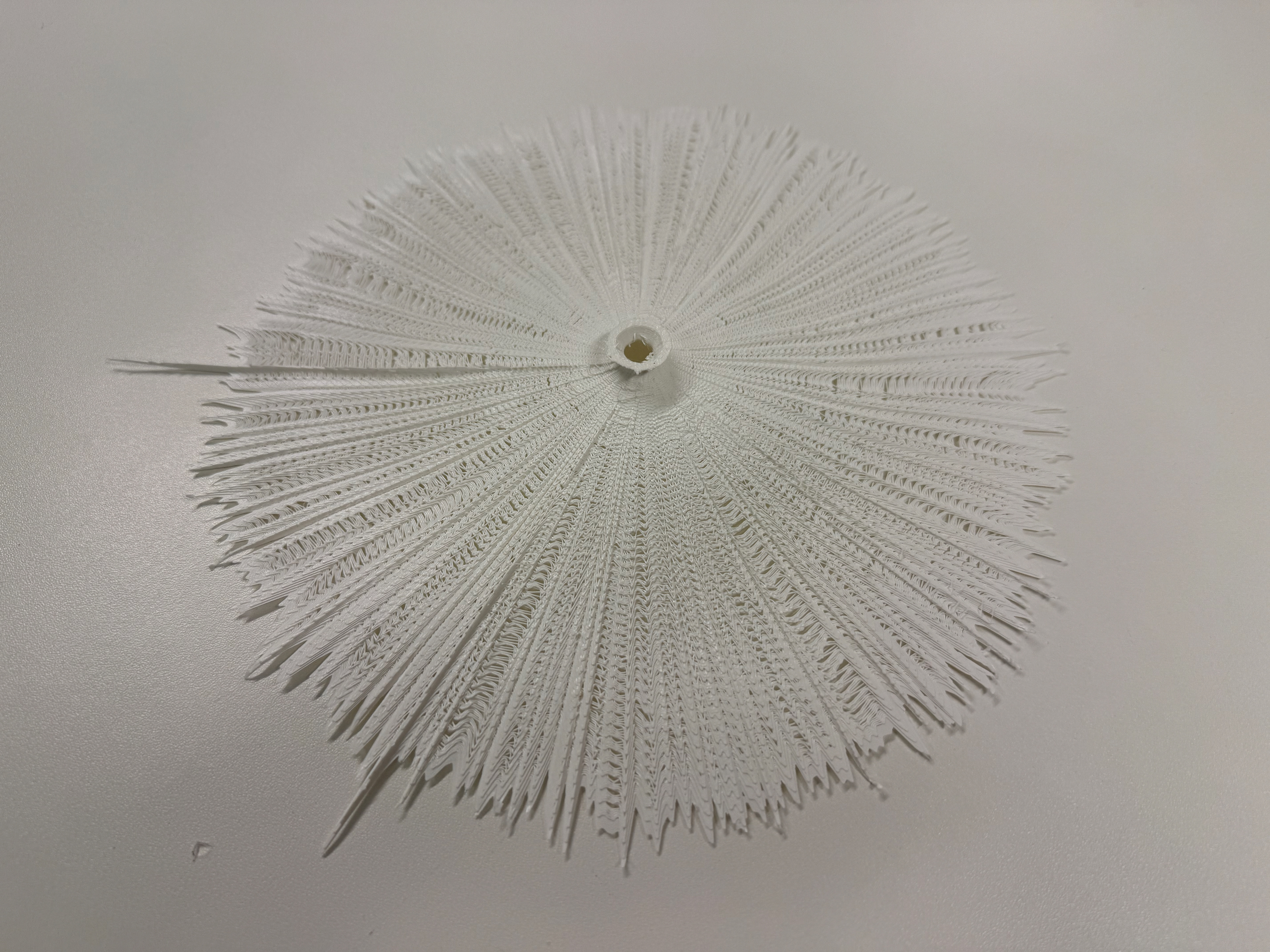

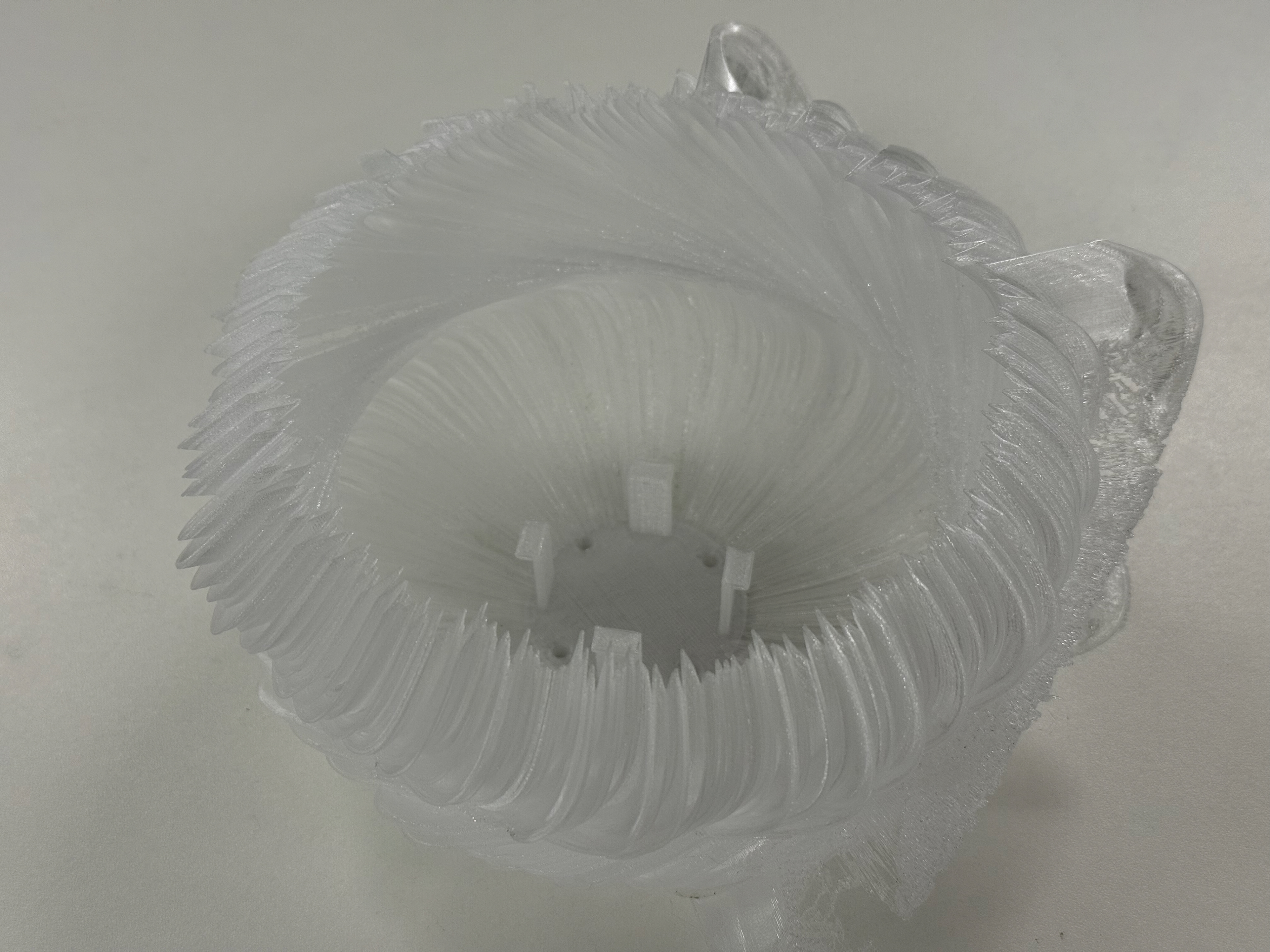

Above view

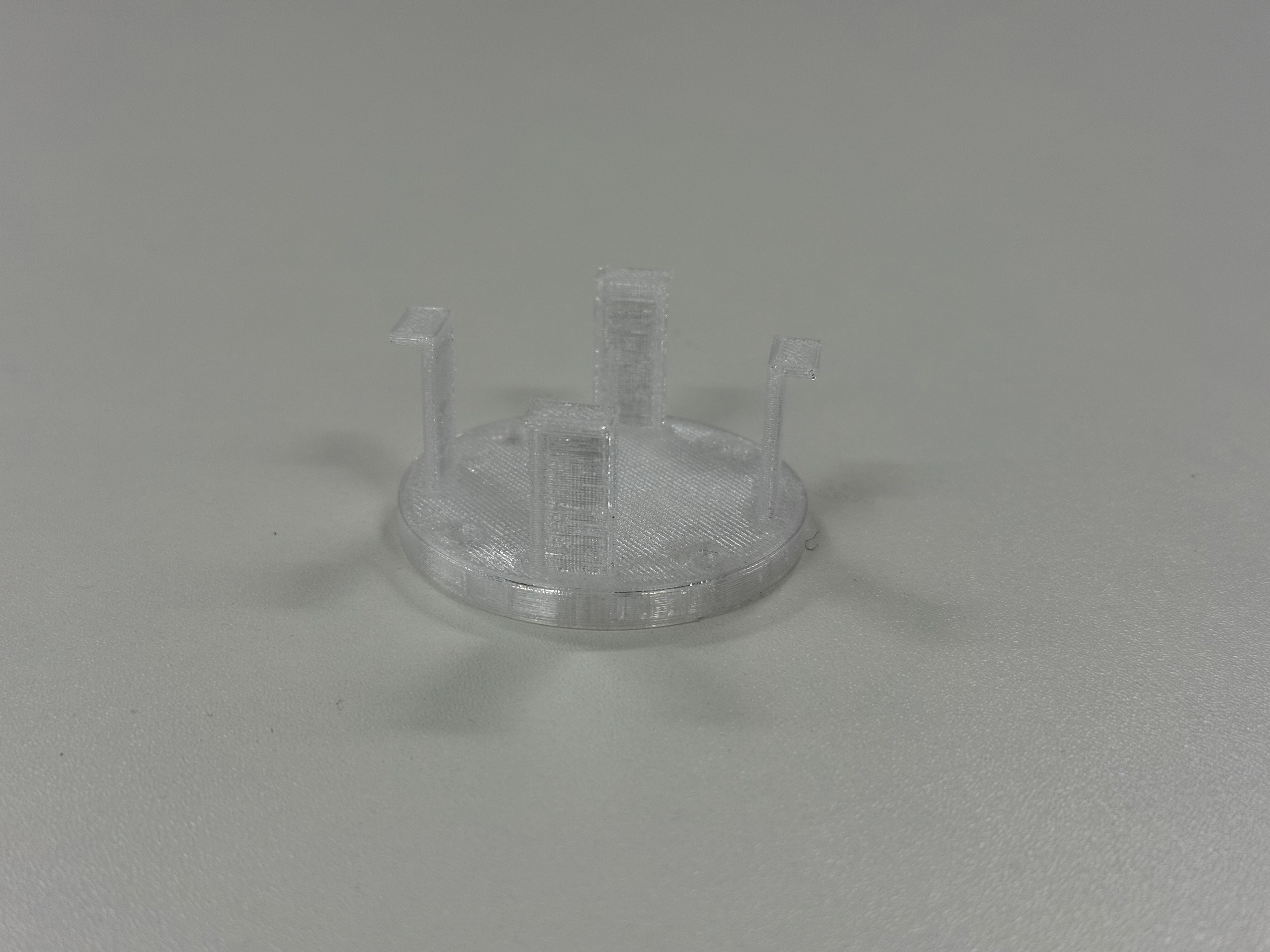

Base

Top

Twists

Twists

Compared to the WASP App 75% scale model

Compared to the WASP App 75% scale model

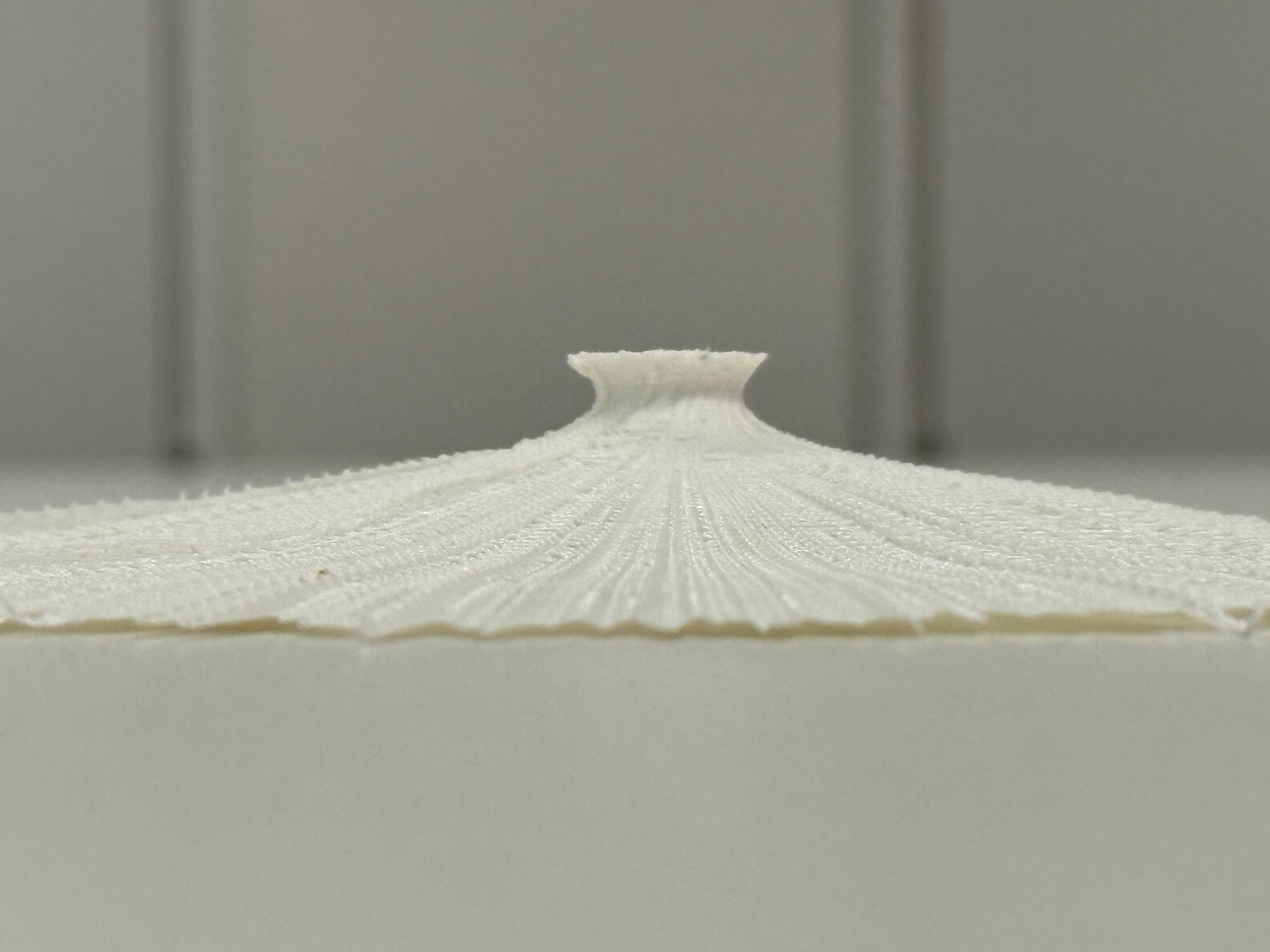

The Cura settings. You can see how short the piece is. I had to scale it down to 60% size just to fit on the bed; it was a very wide object initially.

The slight gradient the printer has to build layers on

Finished print on the bed

I took the skirt off the piece. Side profile with the twist viewable

Flat on a desk

Top side view

Comparison to V6 which was a randomly selected sleep

Comparison to V6 which was a randomly selected sleep

Full Scale on the Print Bed

Some of the lines have printed but others seem to have collapsed

We can see within the "Prepare" section that it is purposely not printing these sections. I obviously didn't do the correct checks before printing.

Although not perfect, the result is far better. This was the best I managed to figure out on my own. I will contact Gary at Print City to see if he has any recommendations.

50% Scale

50% Scale

I have discovered the equivalent setting - "Surface Mode" and set to "Surface". This mode prints a single wall tracing the mesh surface; it has no infill and doesn't allow a base or top to be printed, which may possibly cause some issues for me later on.

50% Scale

50% Scale

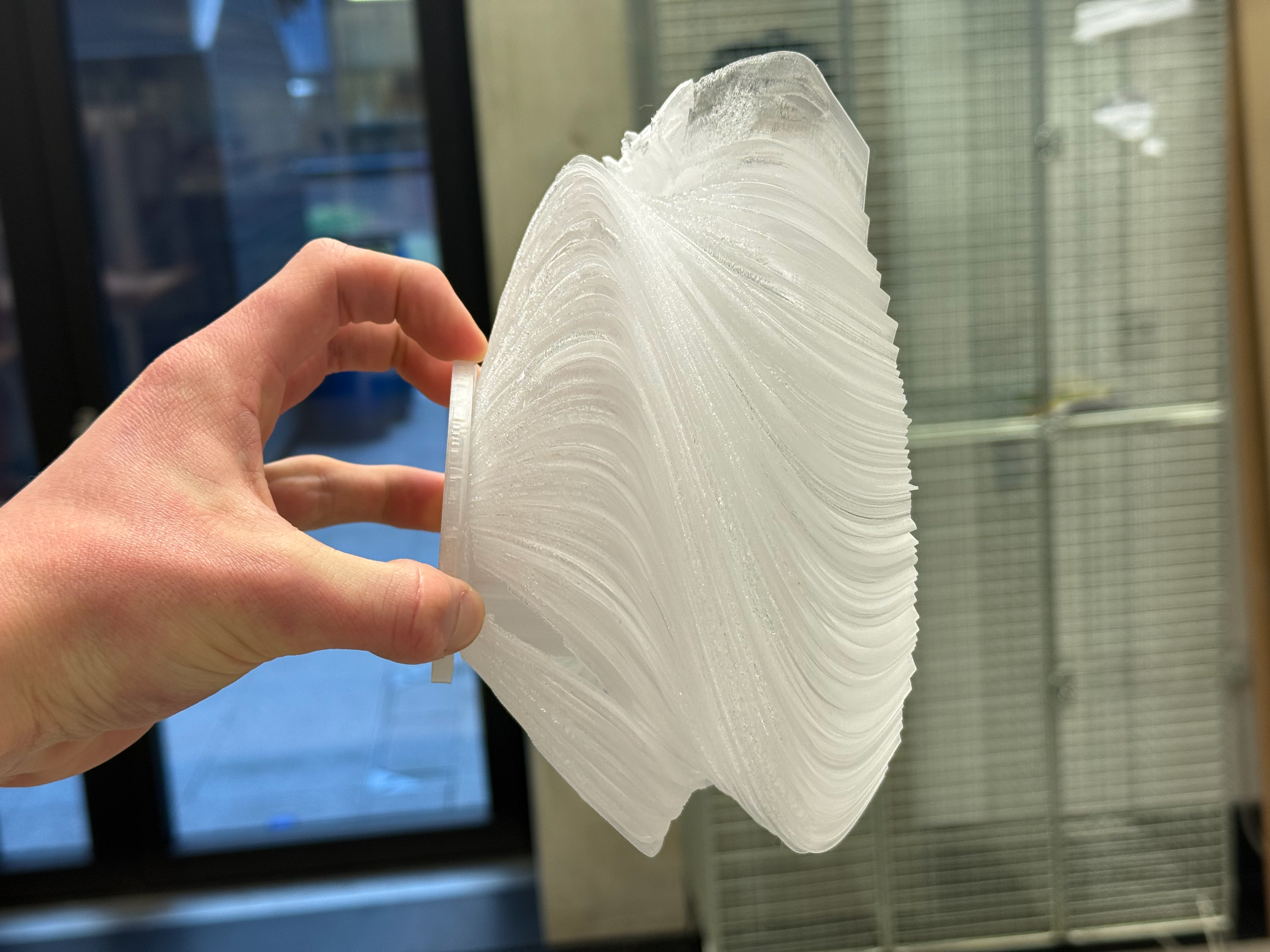

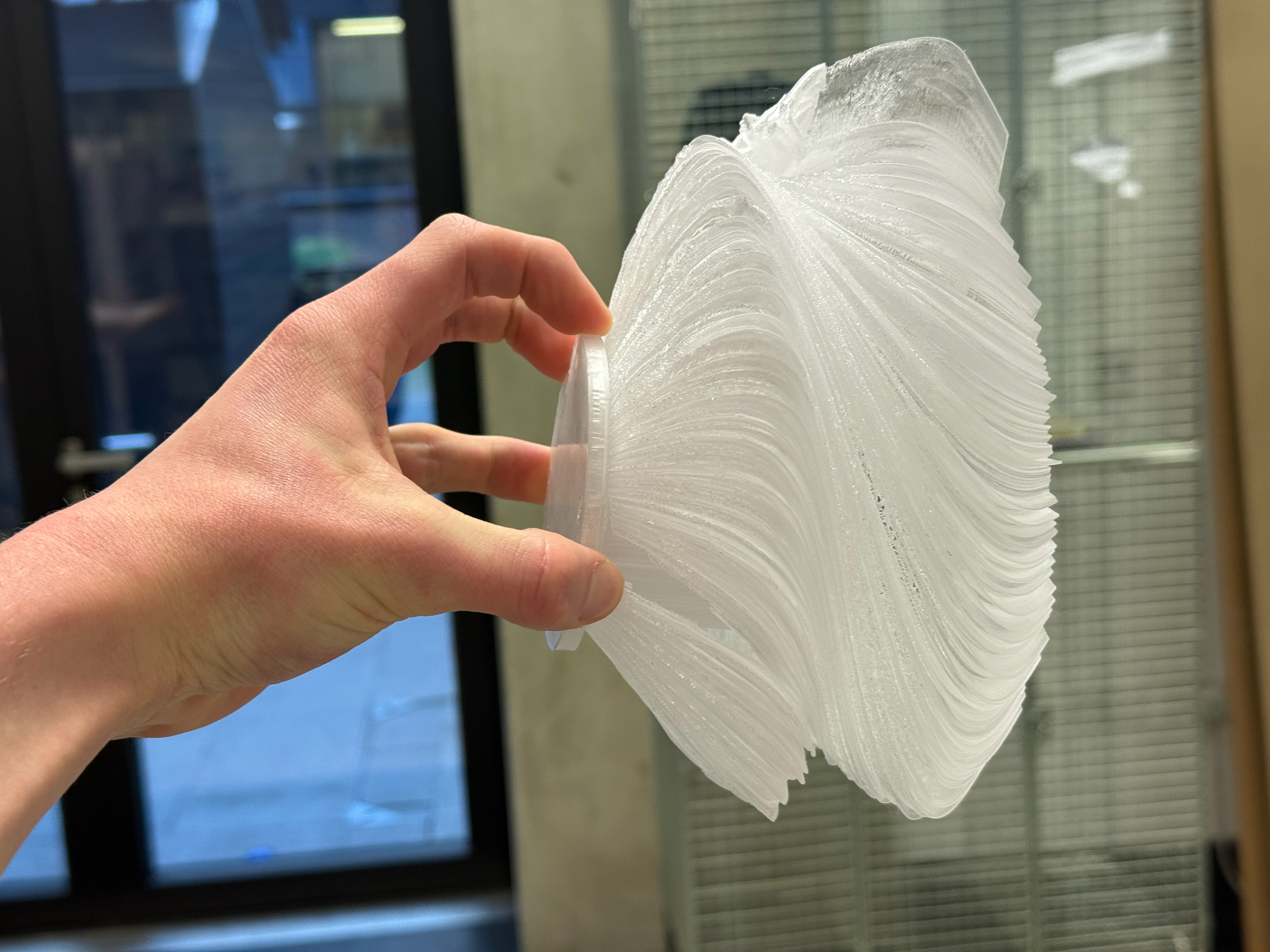

The flexibility of TPU95A

100% scale next to 50%

Compared to the first 100% model

The family of V8 showing the refinement development

The refinement process order

The family in order of refinement

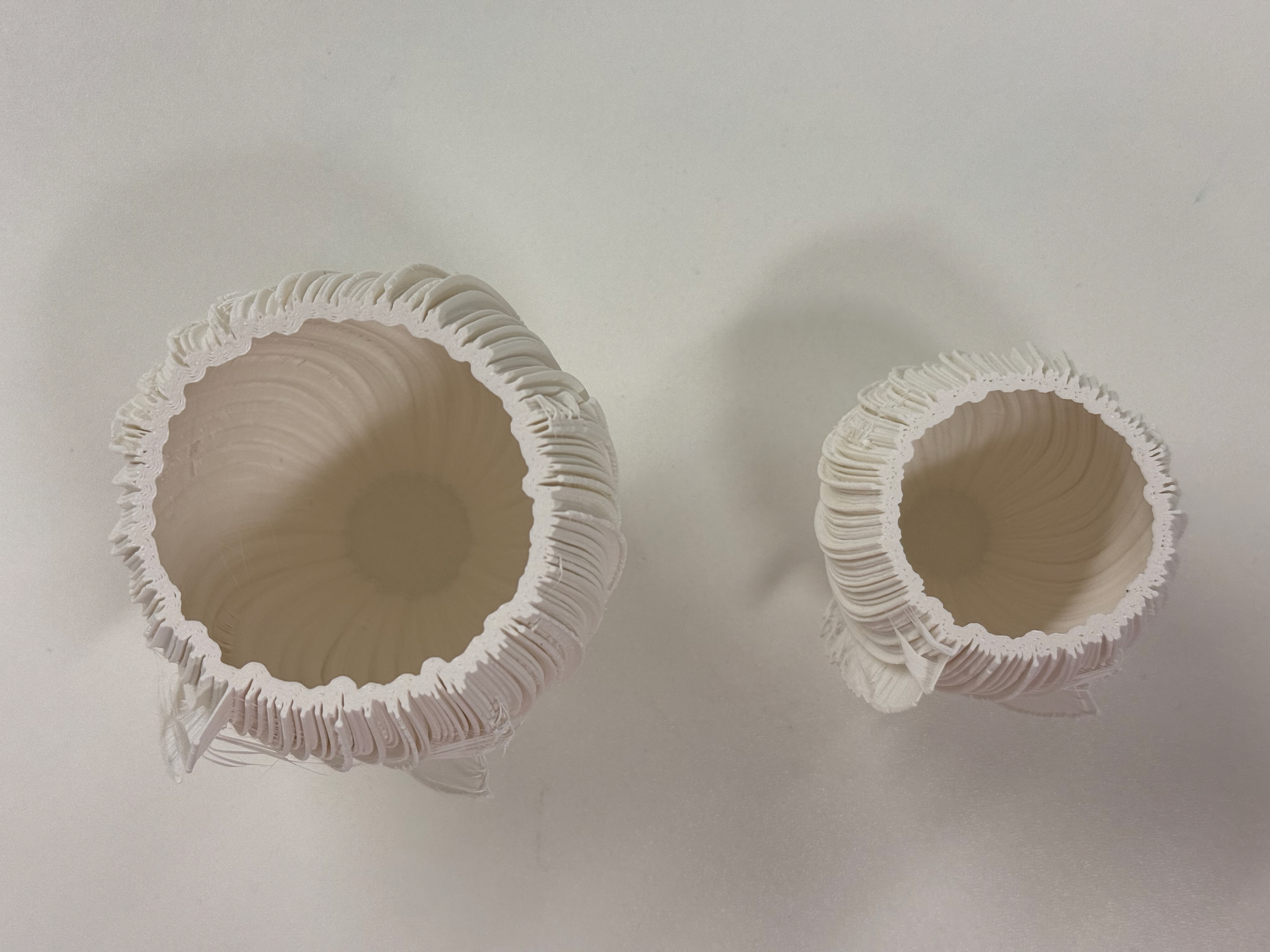

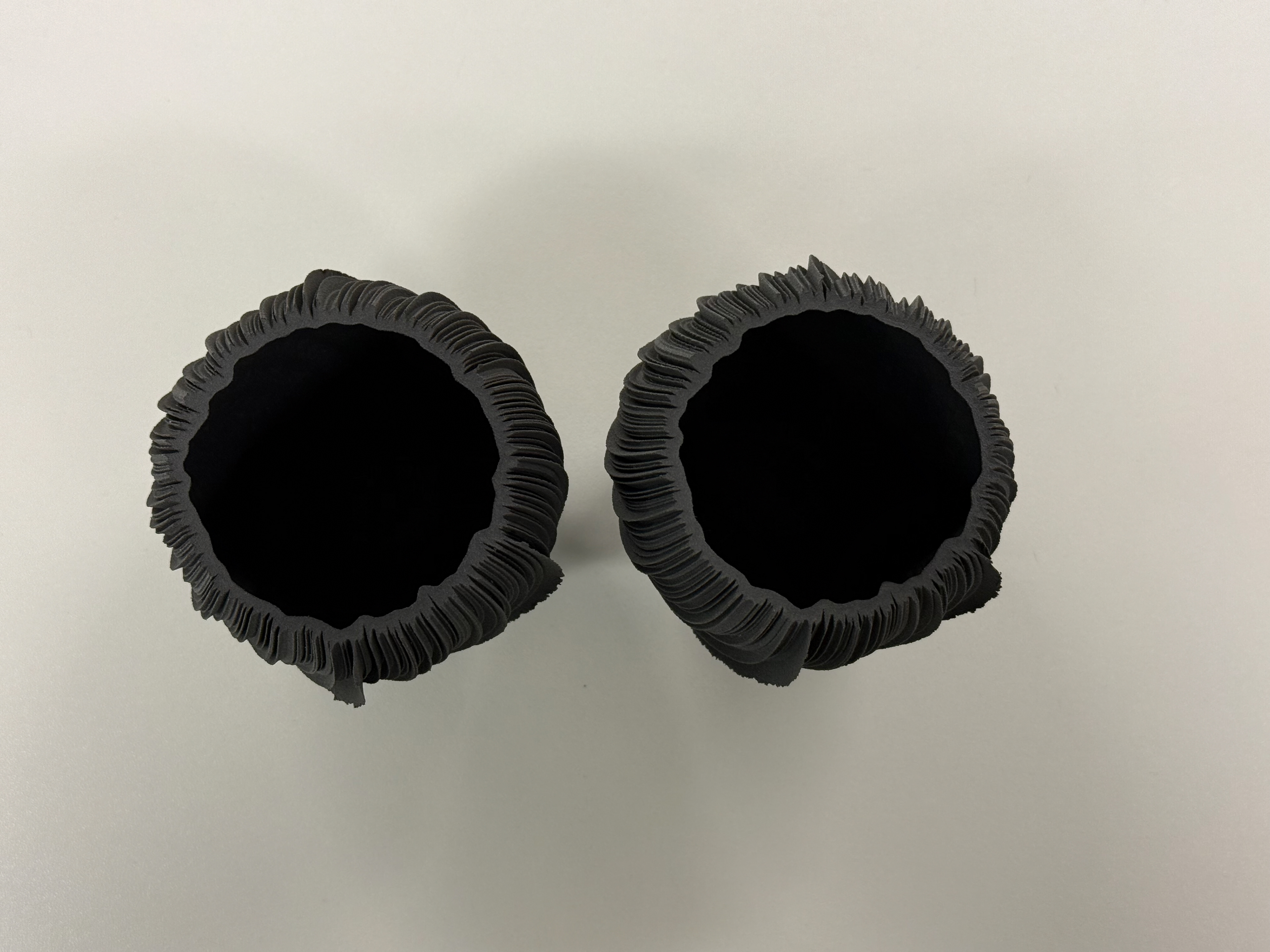

The two identical prints

The two identical prints

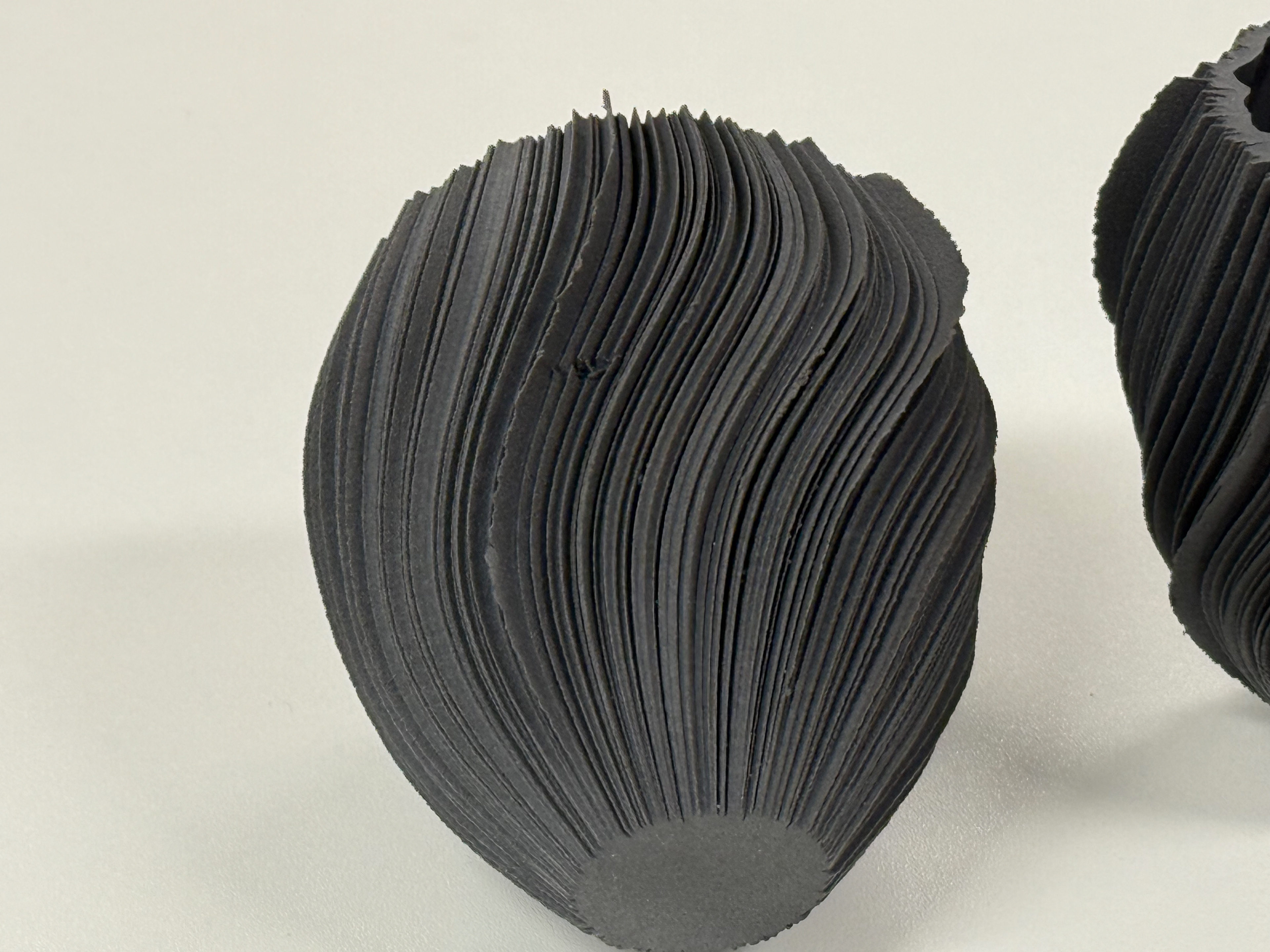

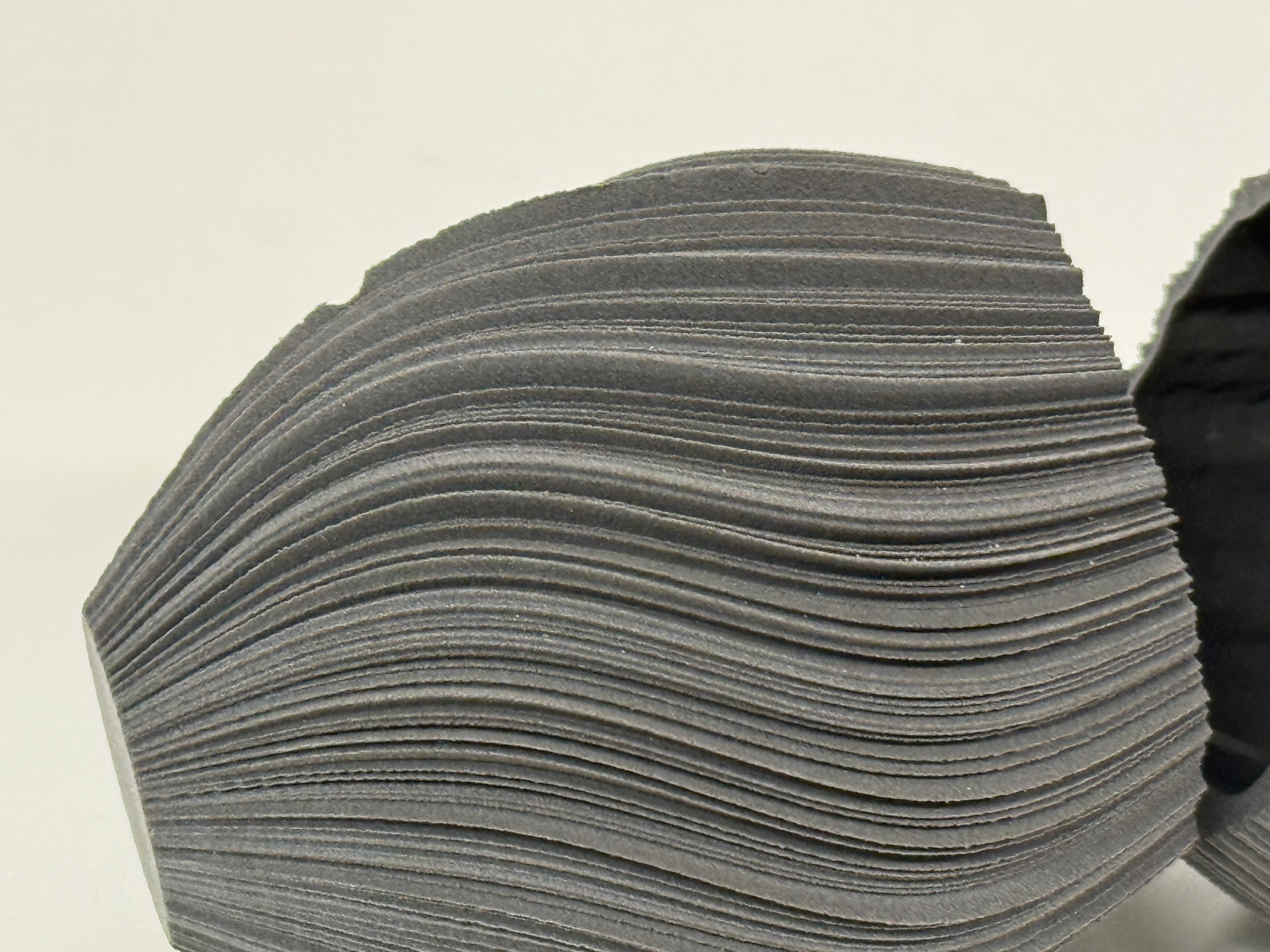

Side profiles

Leading lines

Some of the print came out damaged which may just be because of how the pieces were laid out on the print bed

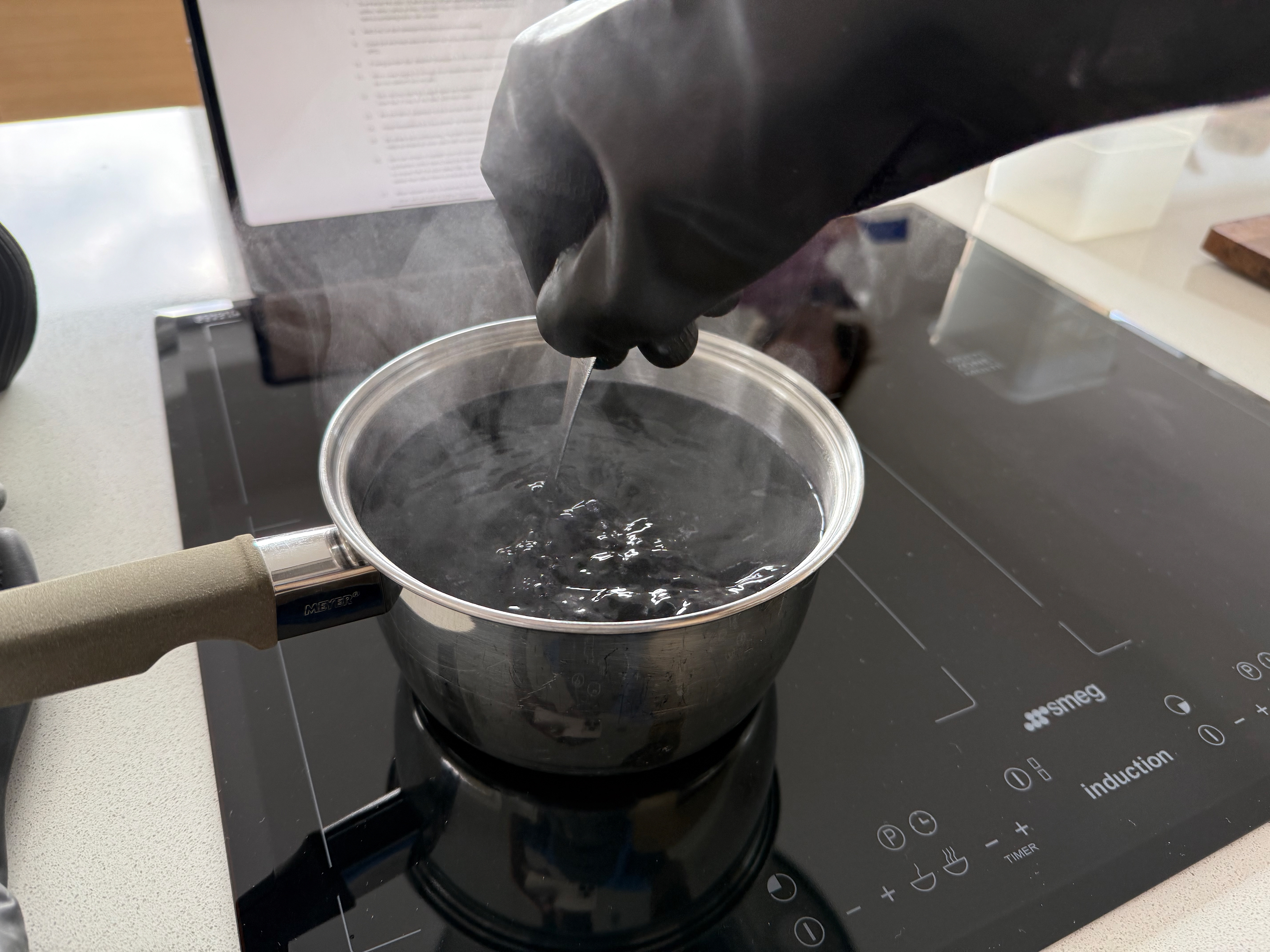

Boiling Water

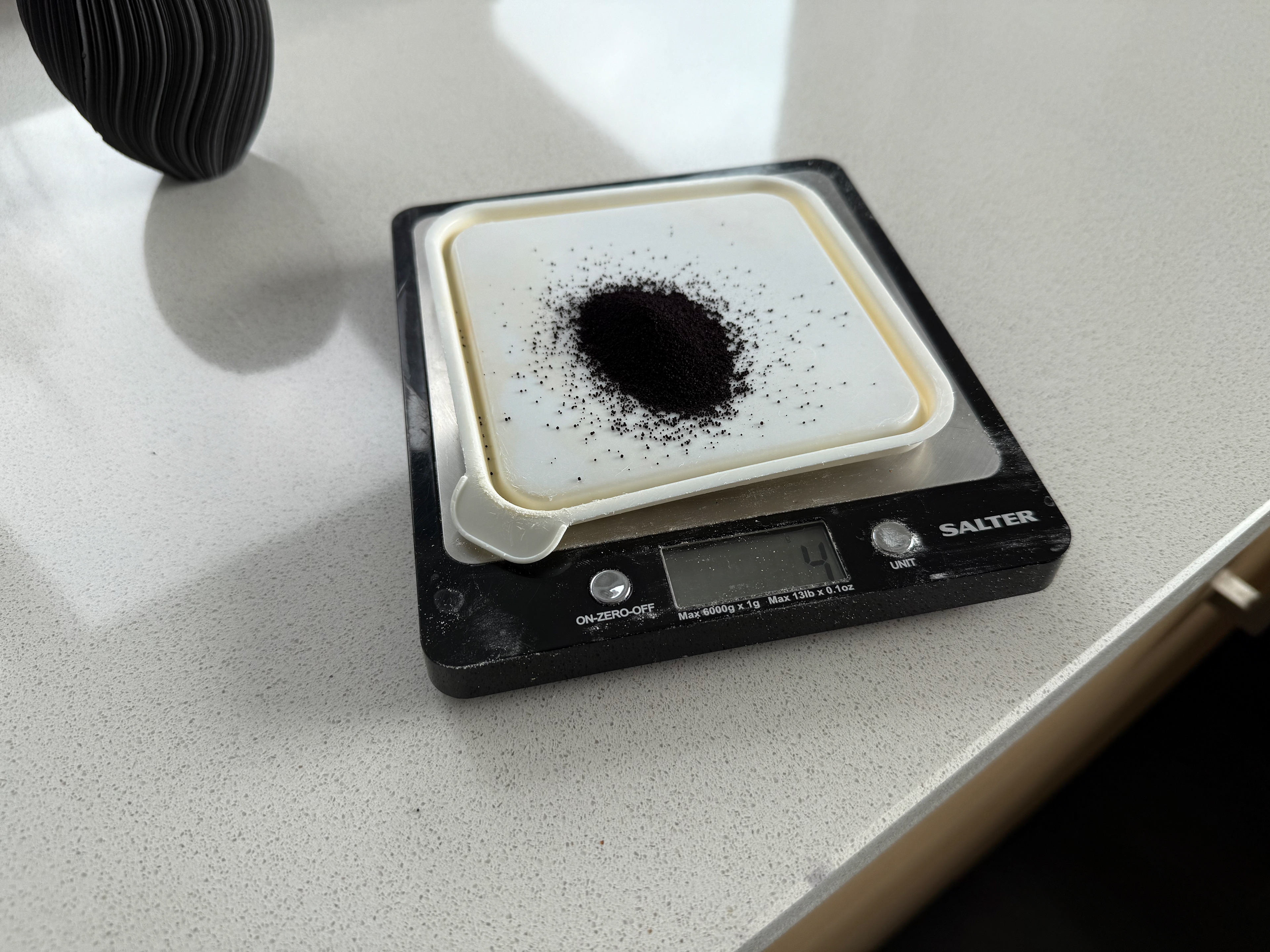

Measure out correct amount of power. 2 sachets (64g) = 1KG of fabric

Stir the power into the boiling water

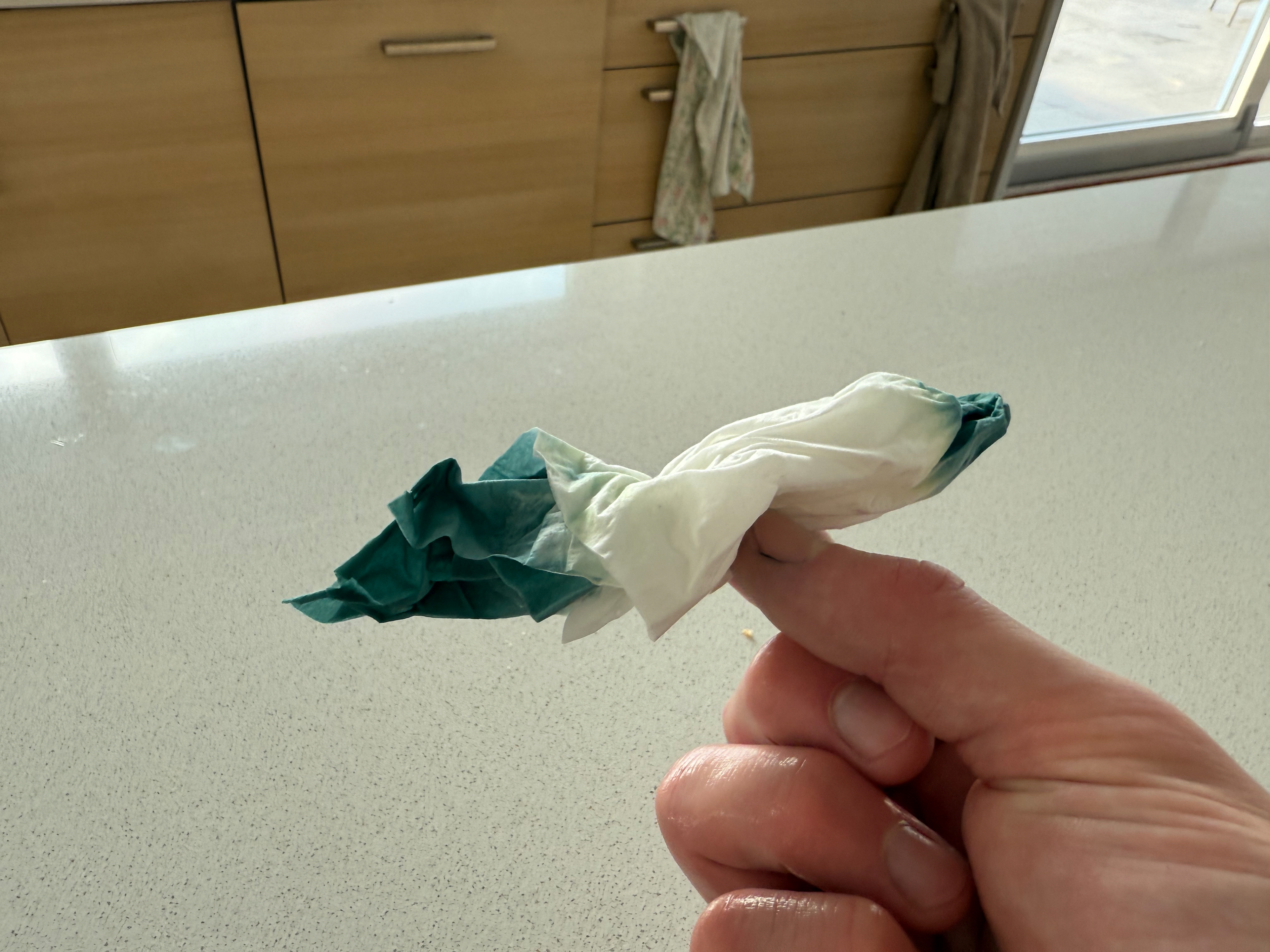

Check the dye is strong enough

Place object in

Move object around

After 30 minutes I took it out

Left upside down to dry

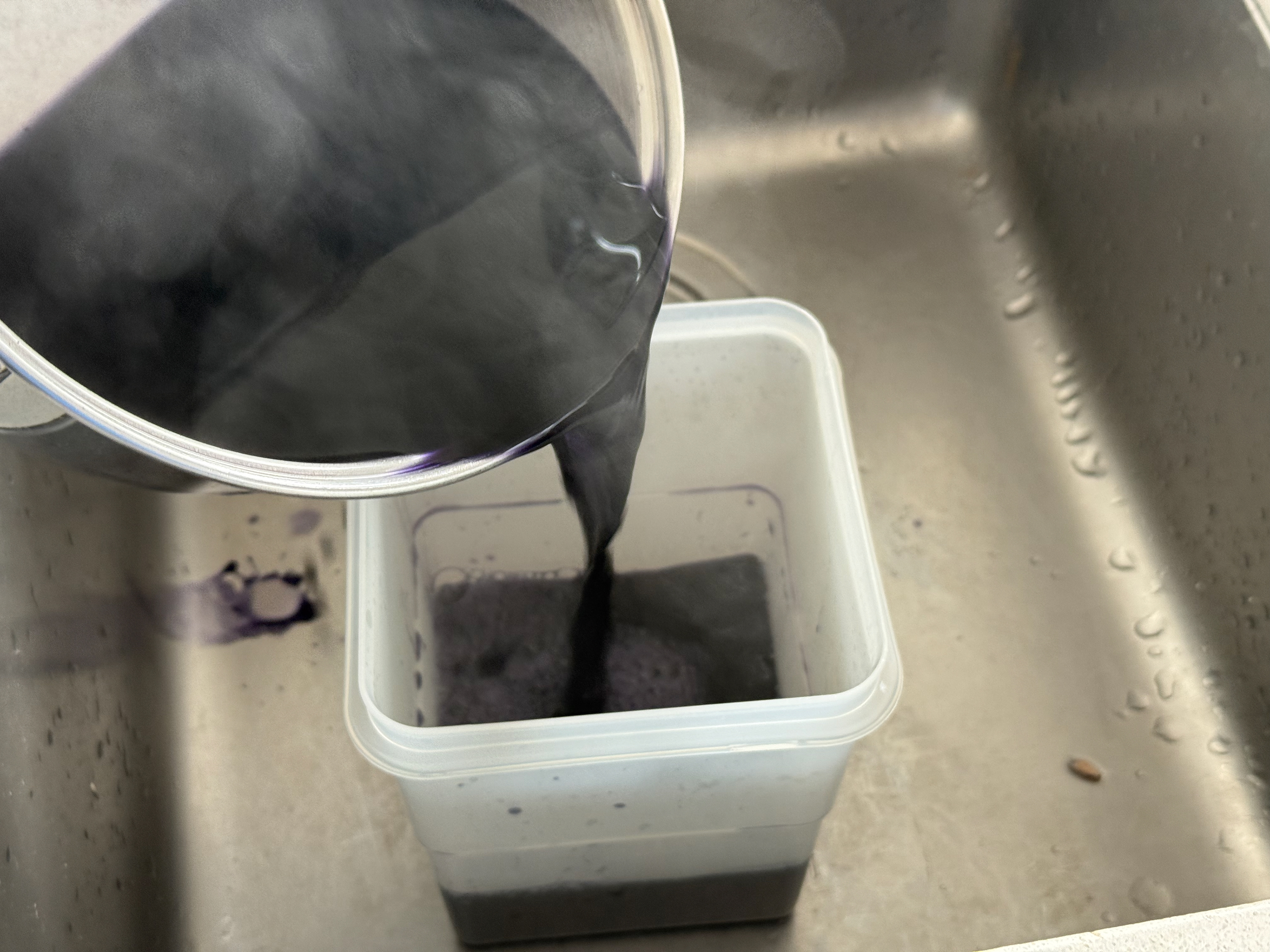

Pour liquid into container for reuse later on.

The tissue test

Drying, a small line looks like it wasn't properly submerged or the dye didn't take.

A fully dyed side

Next to the Navy Blue

In the natural sunlight

In the natural sunlight with the Navy Blue

Side by side on a table

Side by side next to the dye boxes

Power weighted out

Tissue colour test

Purple and Green

Purple and Green

Purple and Green

Purple and Green

Cura settings with supports

At this point in the print, I noticed a small issue - the print was flexing up which caused the extruder and casing to slightly catch on the side however it hadn't done any damage so I left it

Finished Print

The support's couldn't be fully removed without casing damage

There were still sections it failed to print but considering supports didn't help, there isn't much I can do

Cura settings

The printed piece

Piece inside the object

Doesn't hold it straight

Less tall and used the backing to stop slides

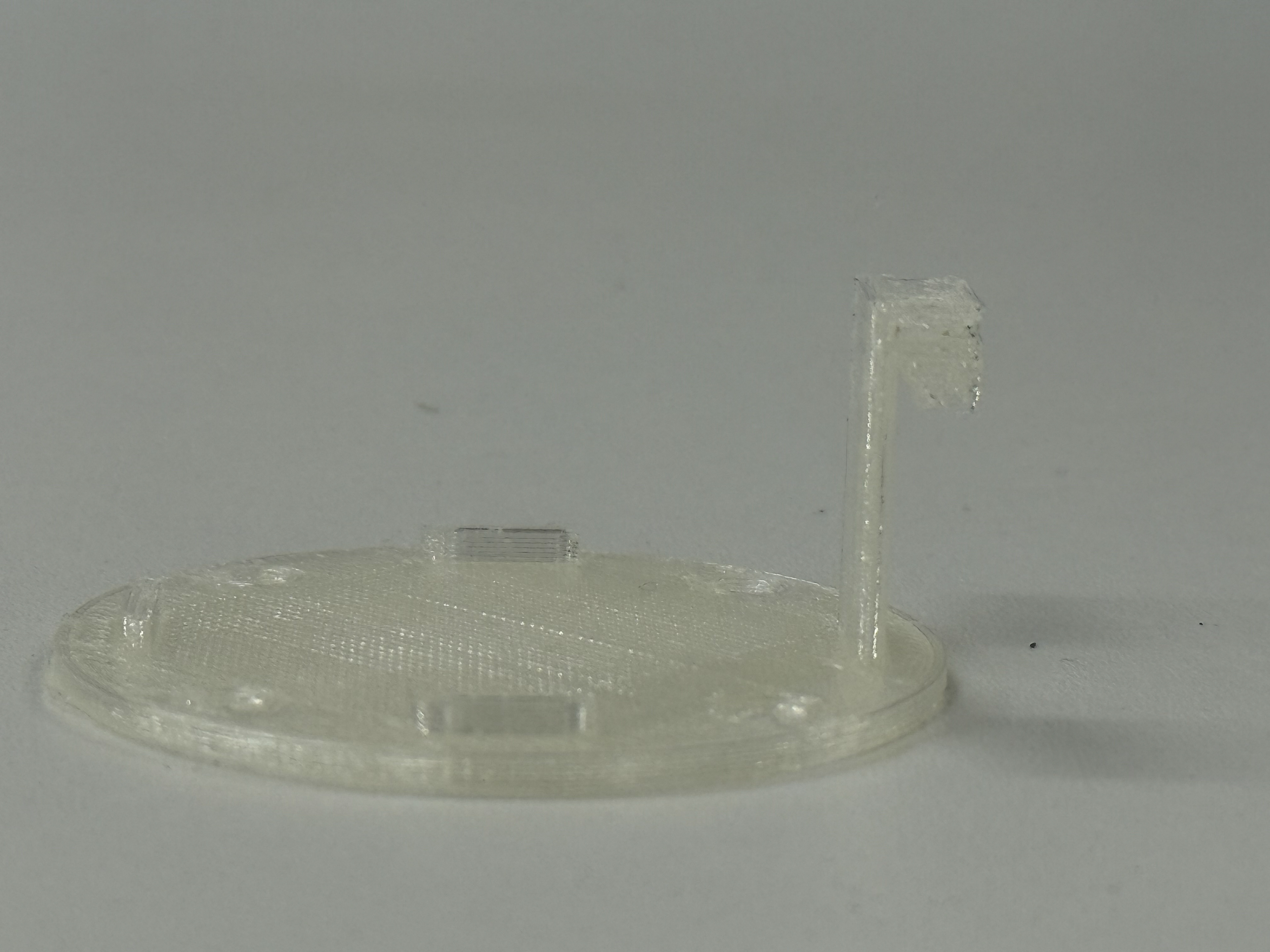

Cura Settings for both

Support block and part broken off

Support block and part broken off

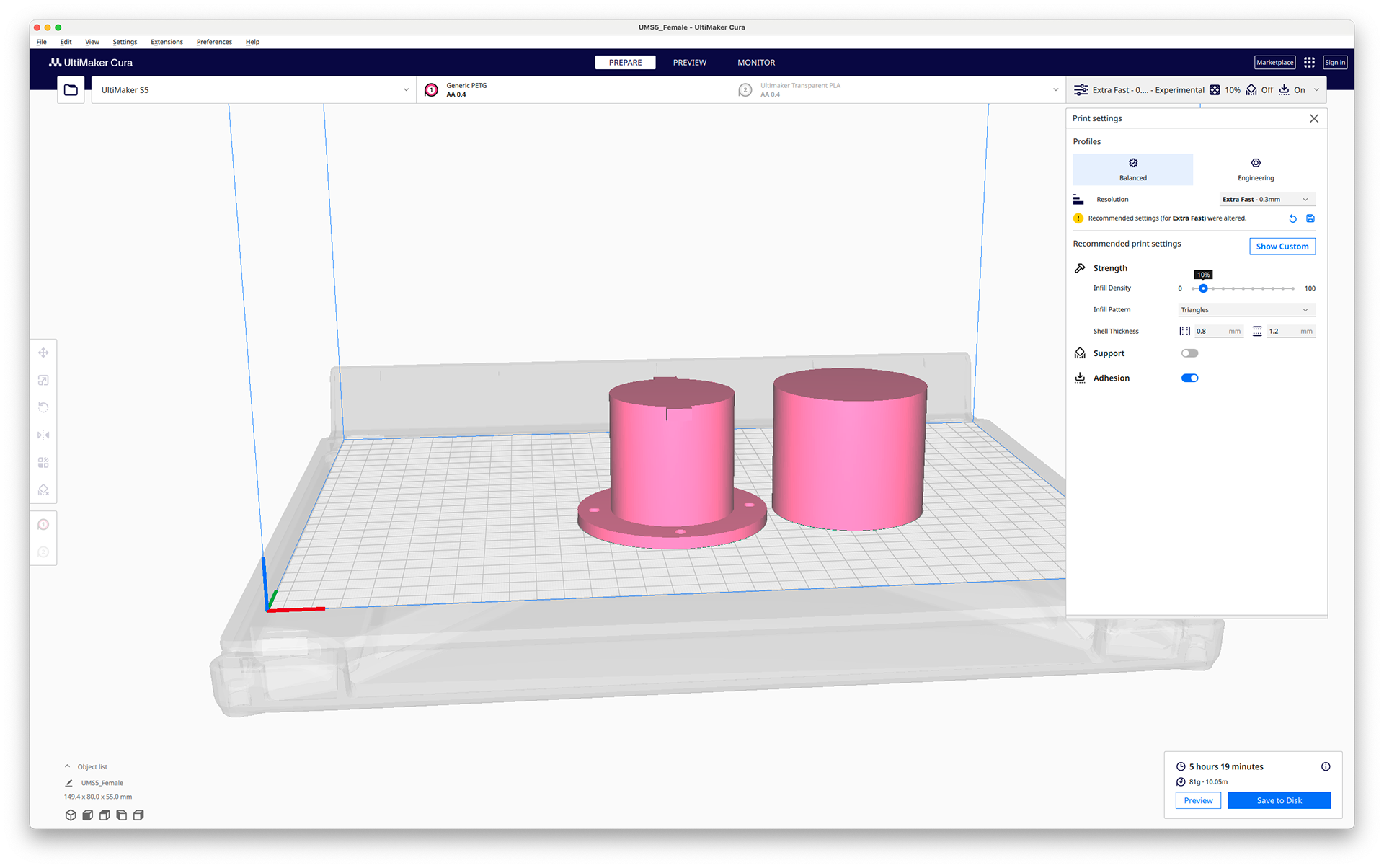

Cura settings

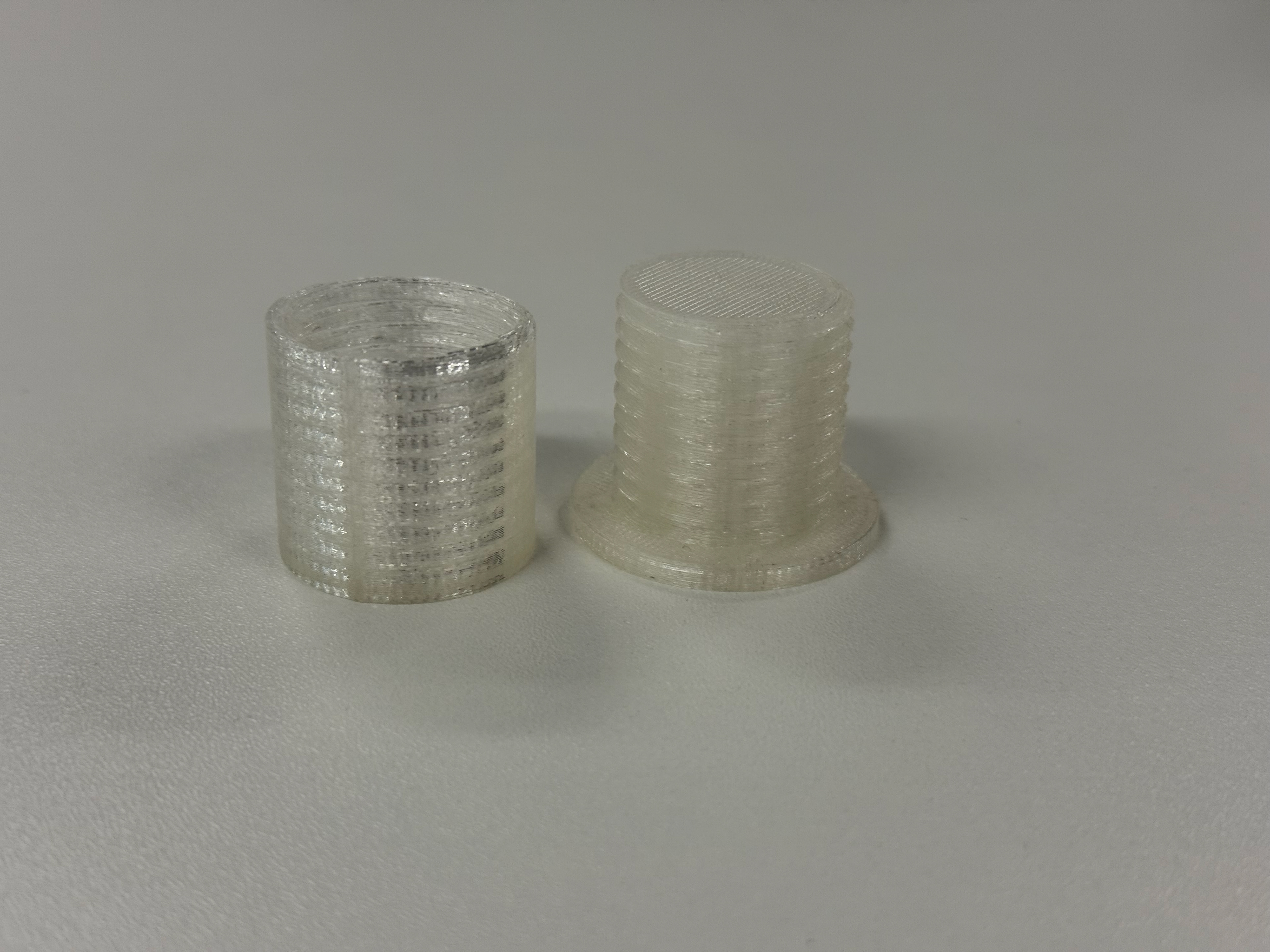

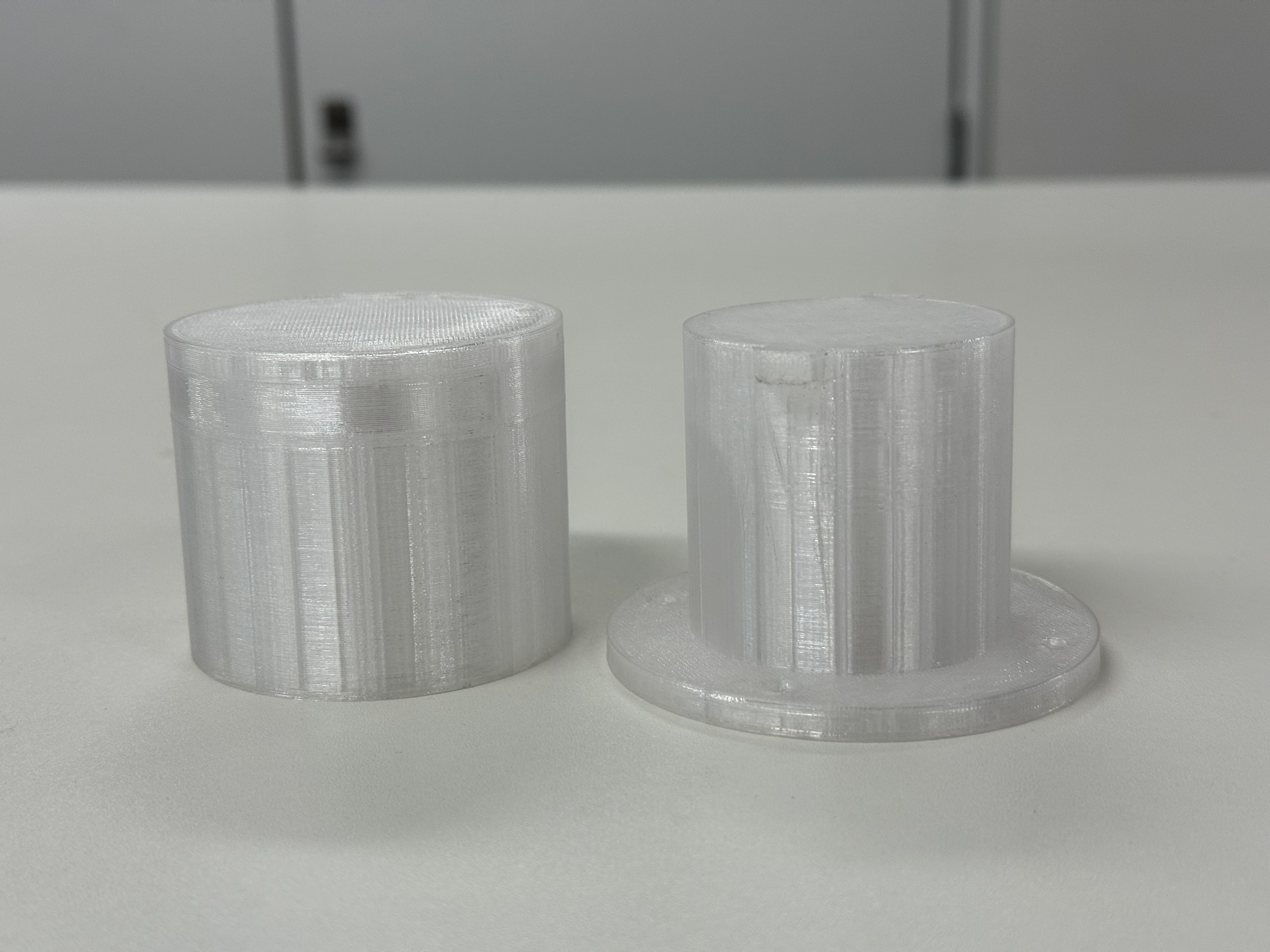

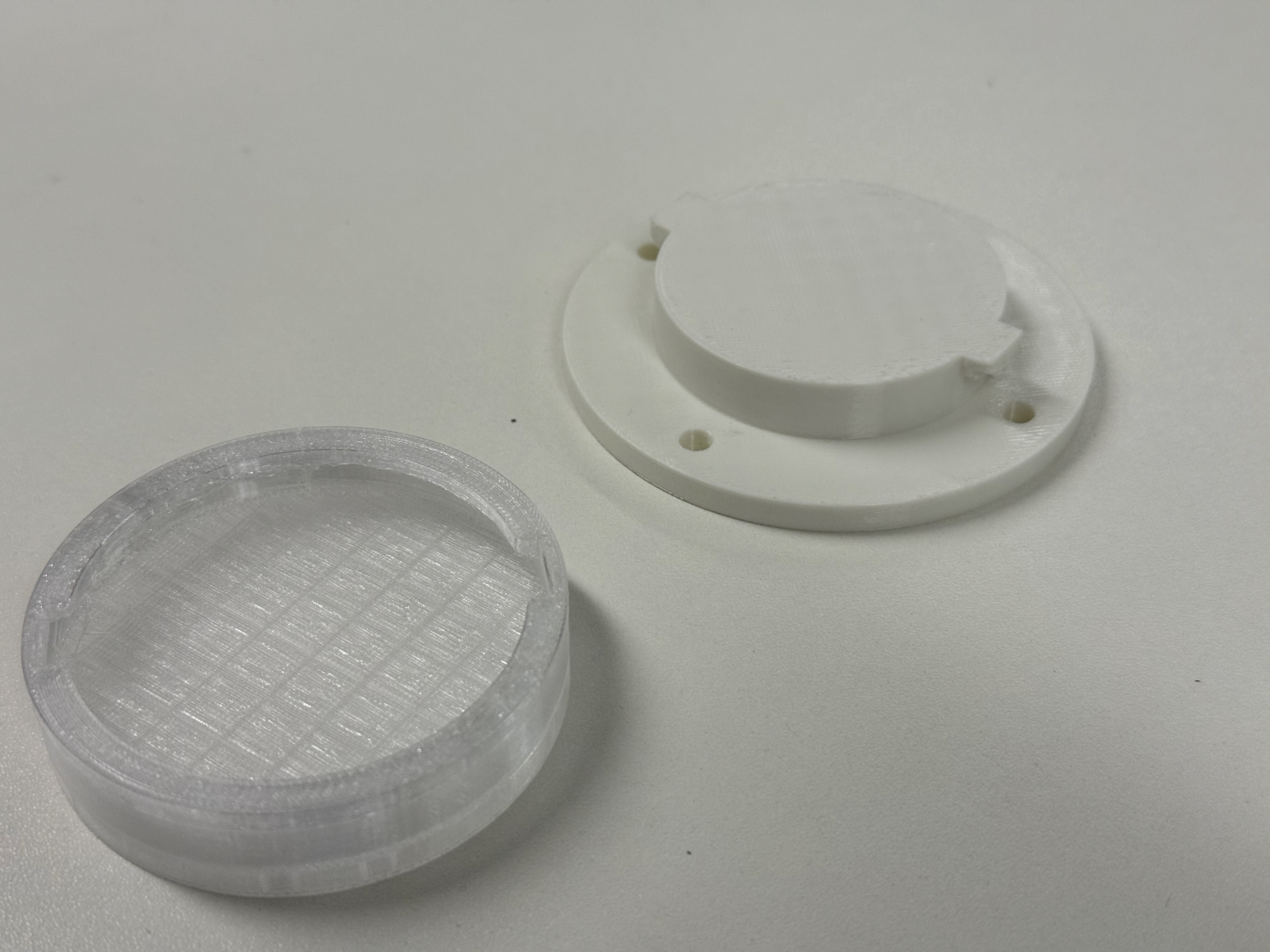

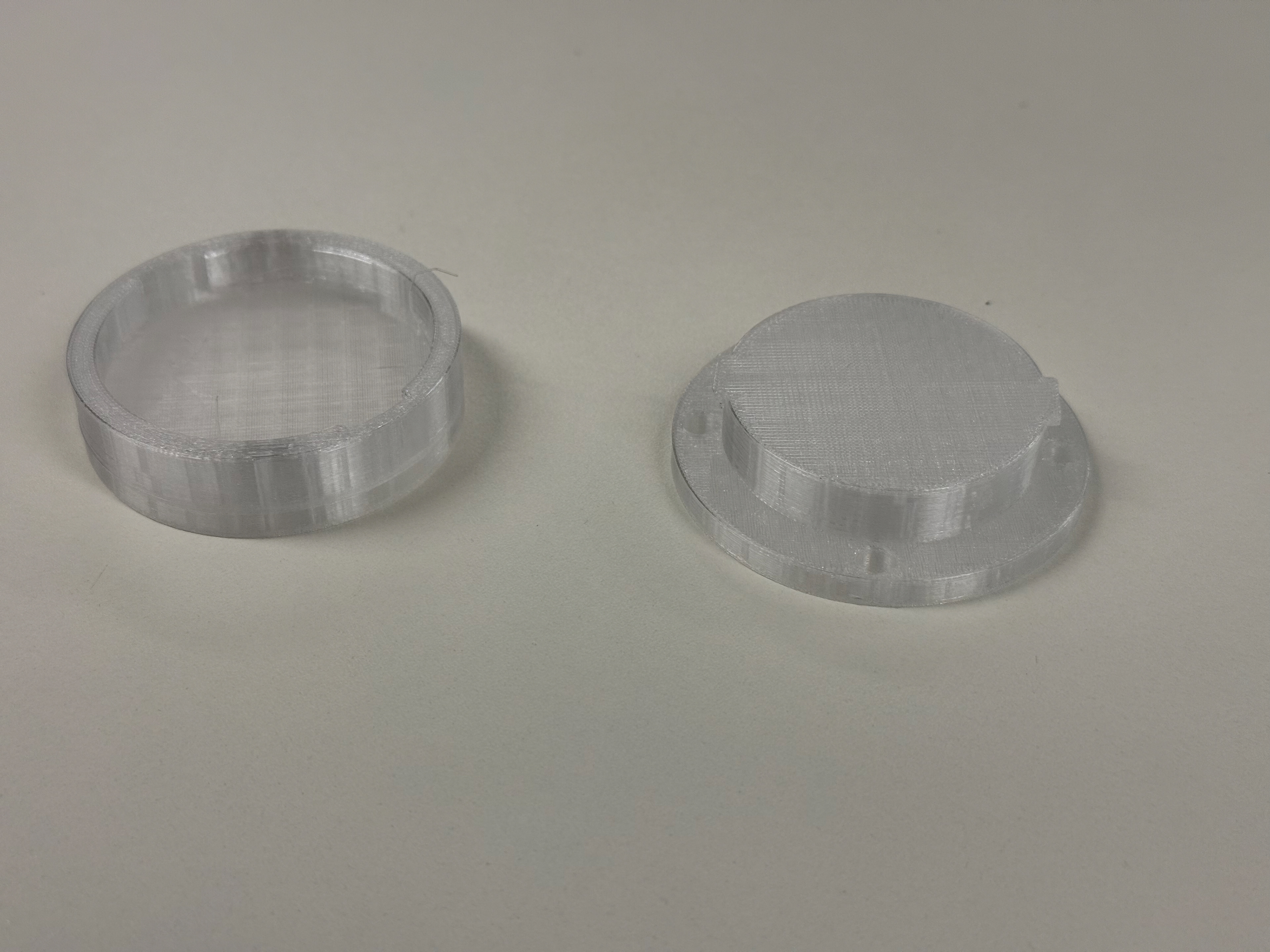

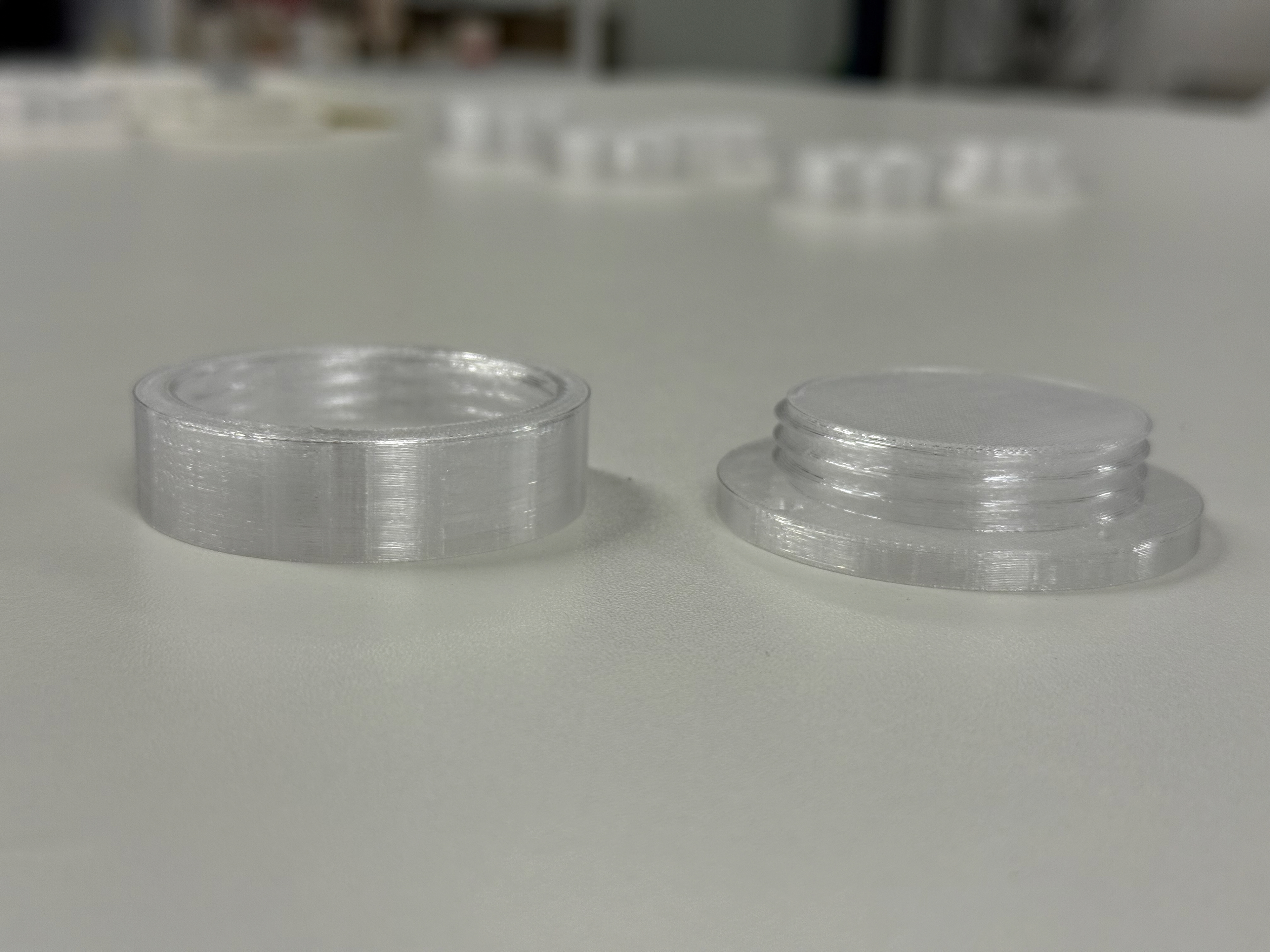

The two parts

I didn't account for tolerance

3% tolerance applied

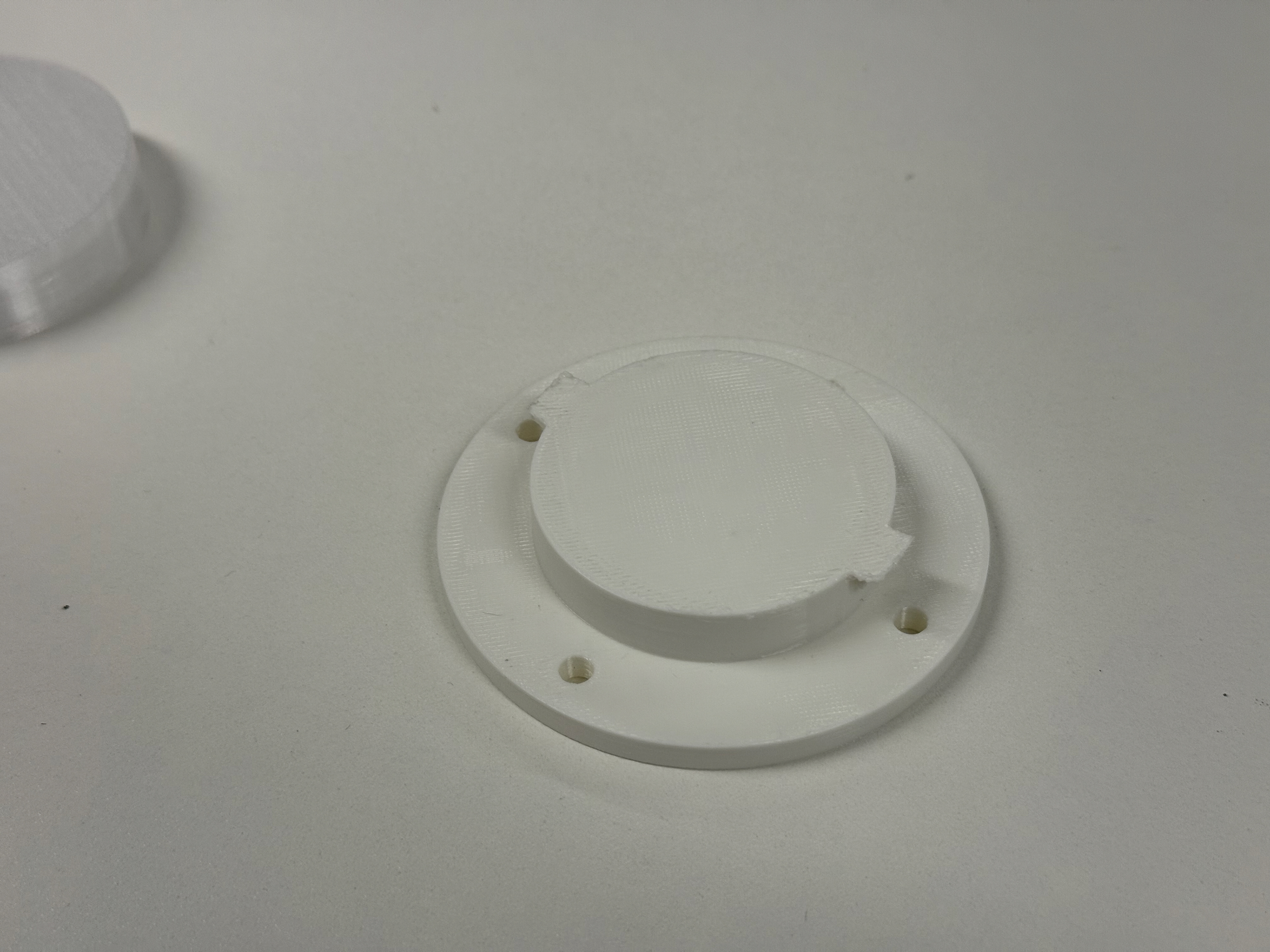

Added screw holes

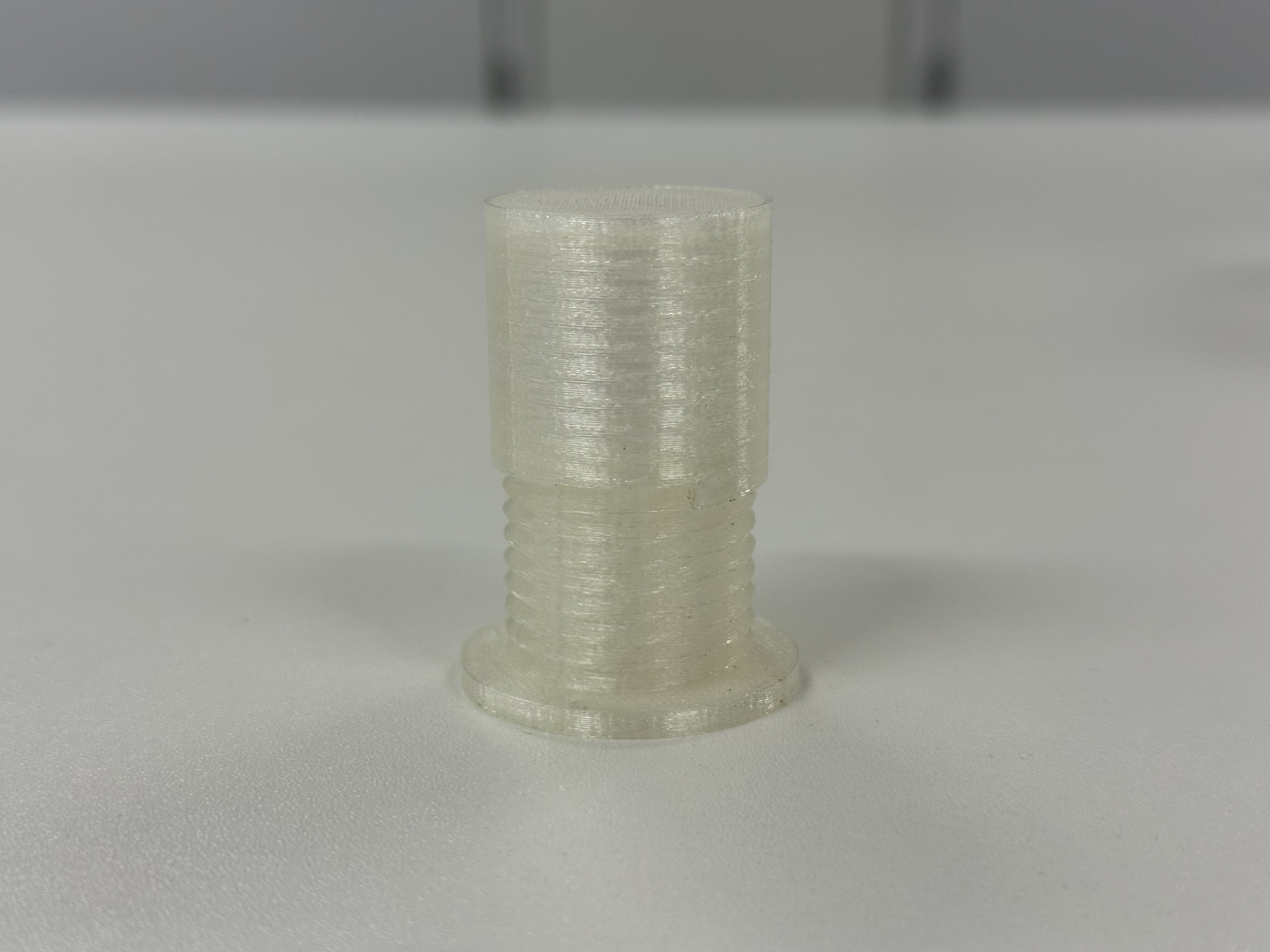

the two parts

Still not enough tolerance

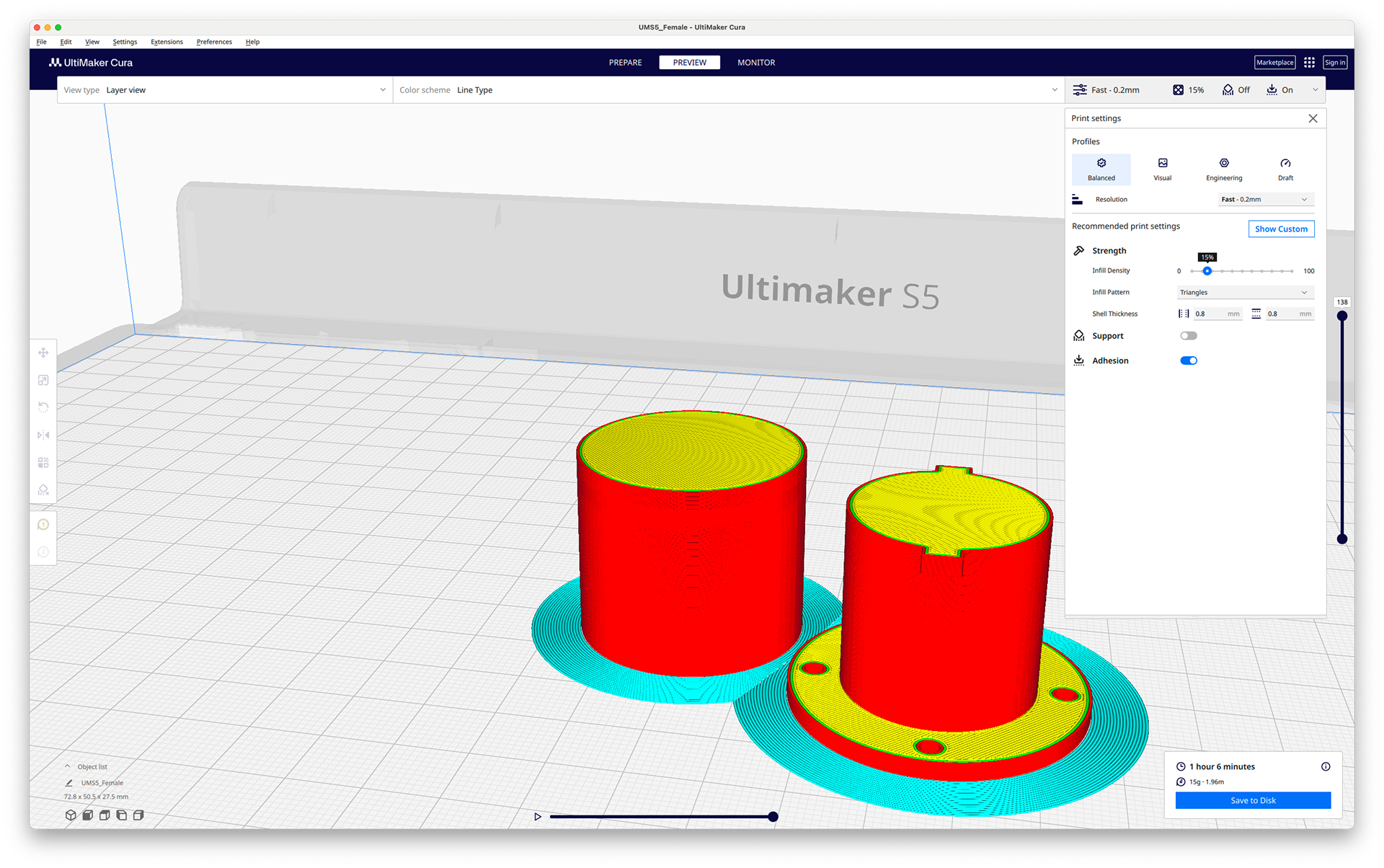

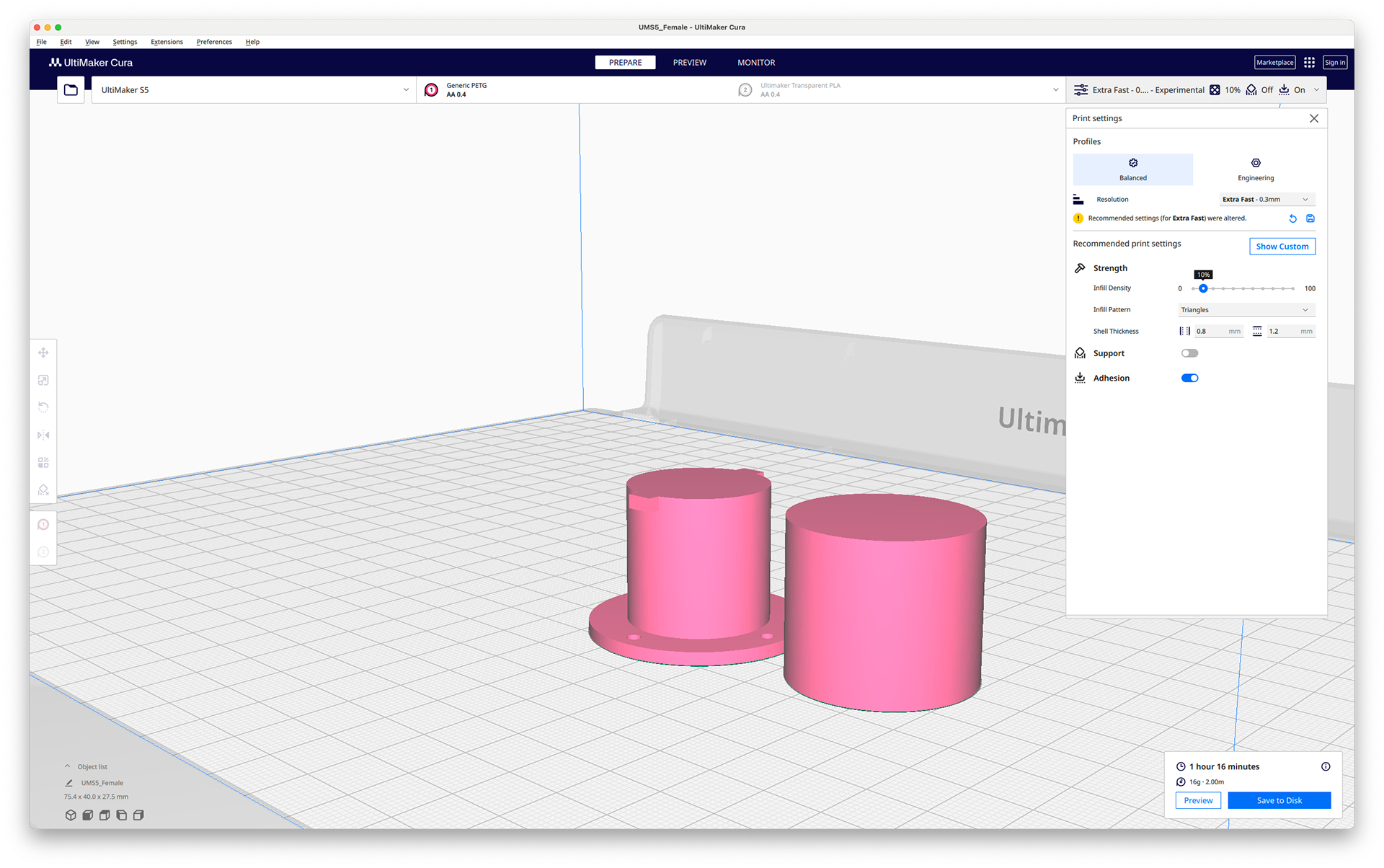

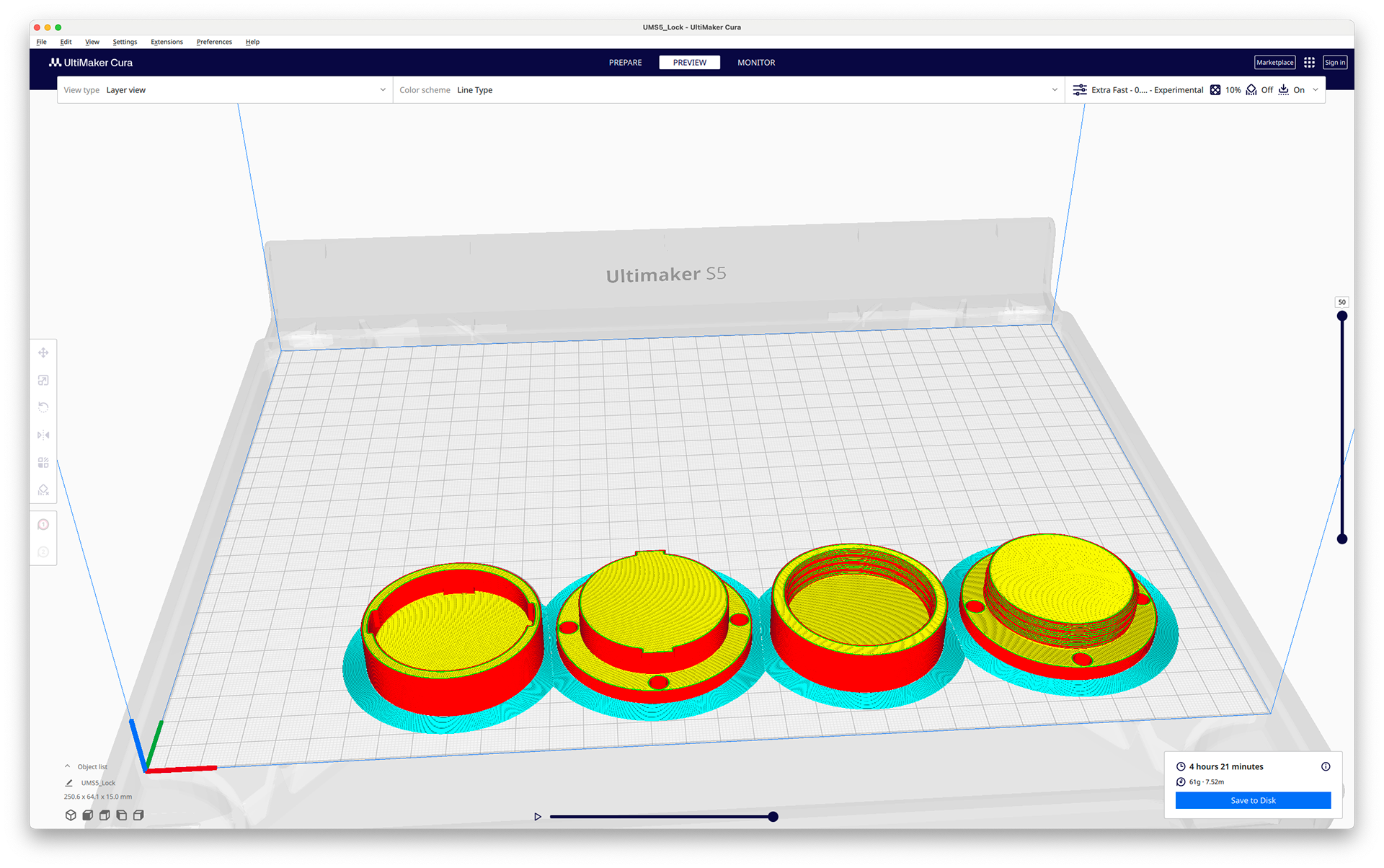

Cura settings

Fit together but slightly too small tolerance

Separate parts

Rescaled for tolerance

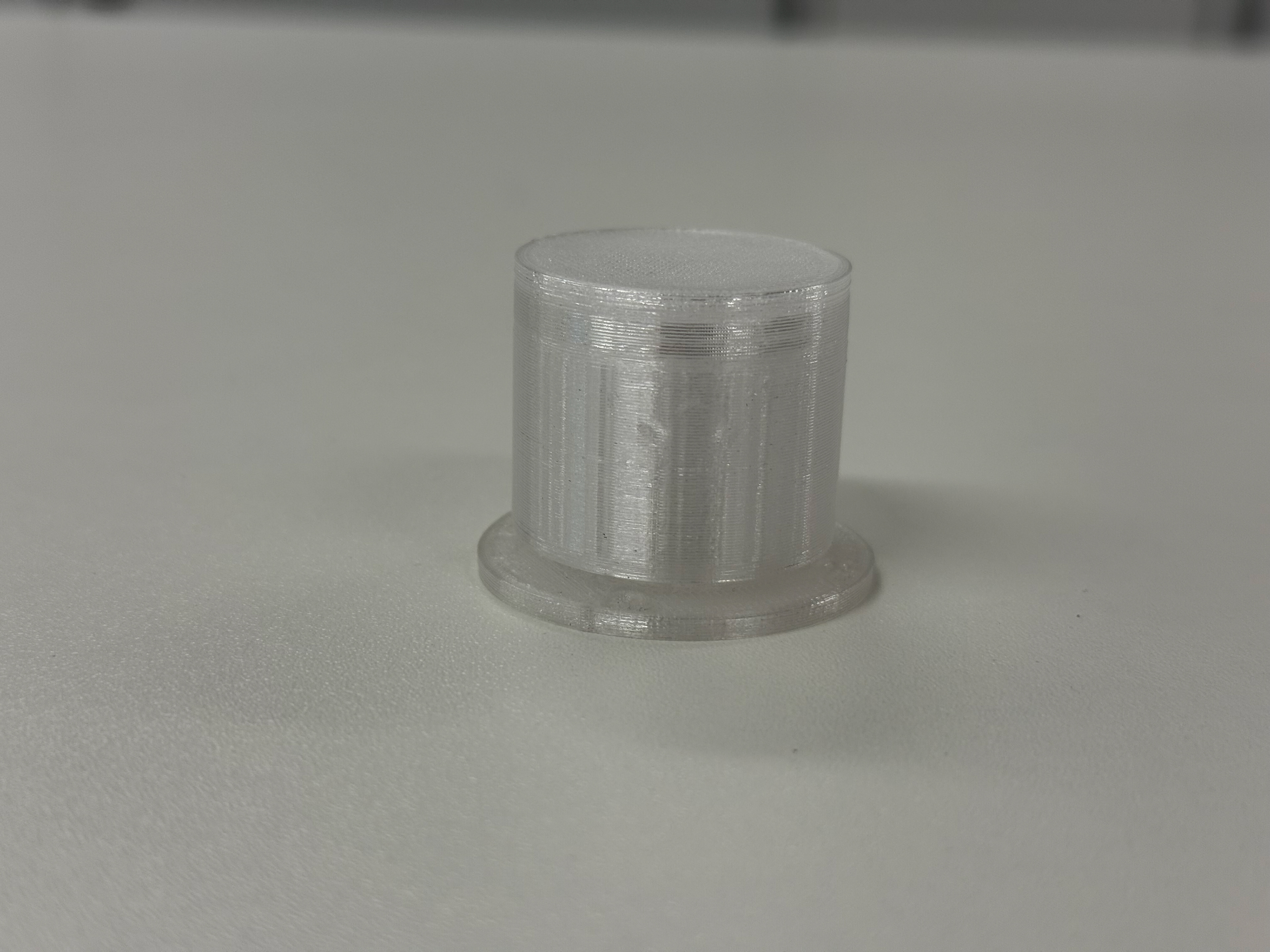

Fit together perfectly

Cura settings

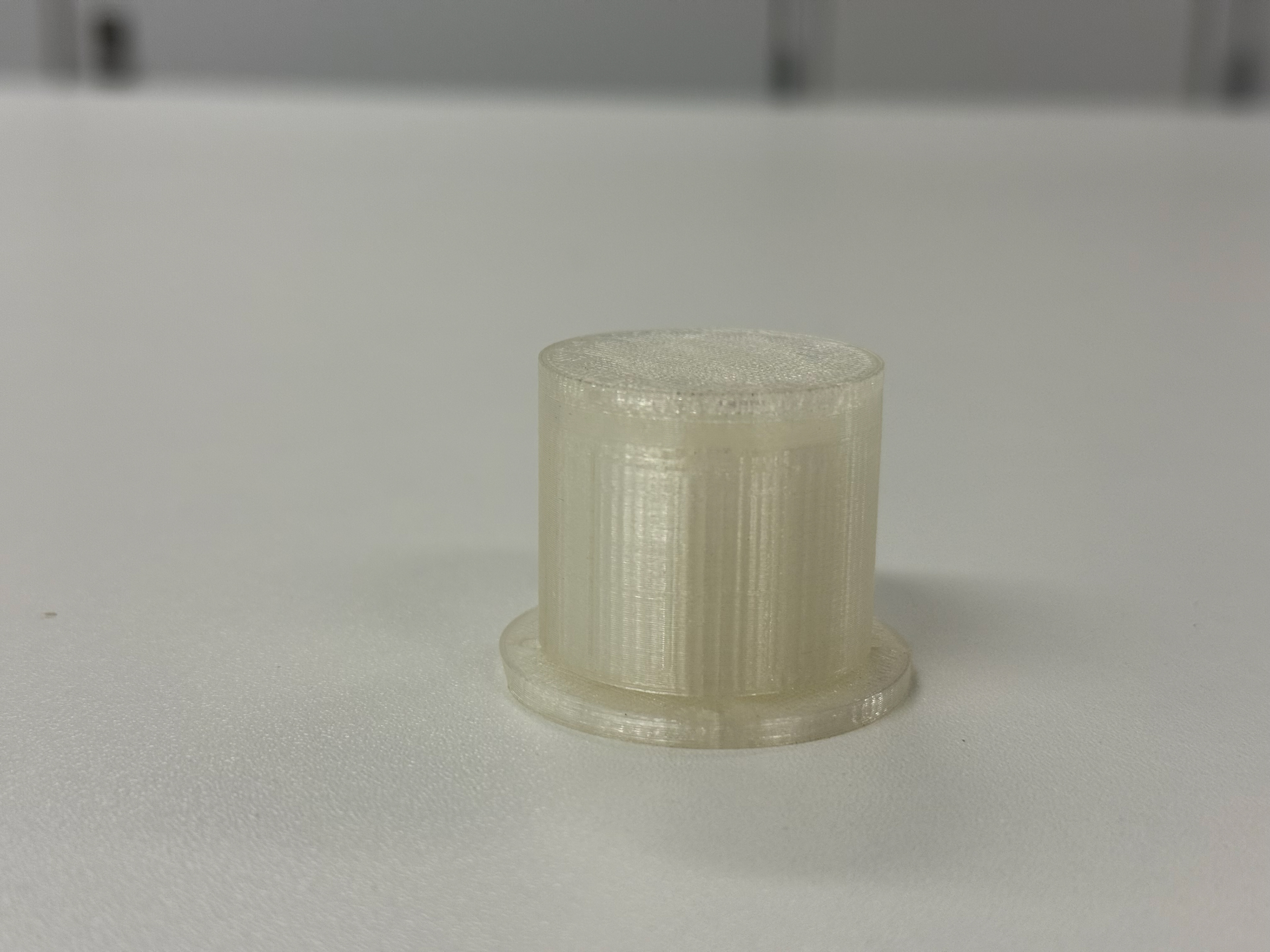

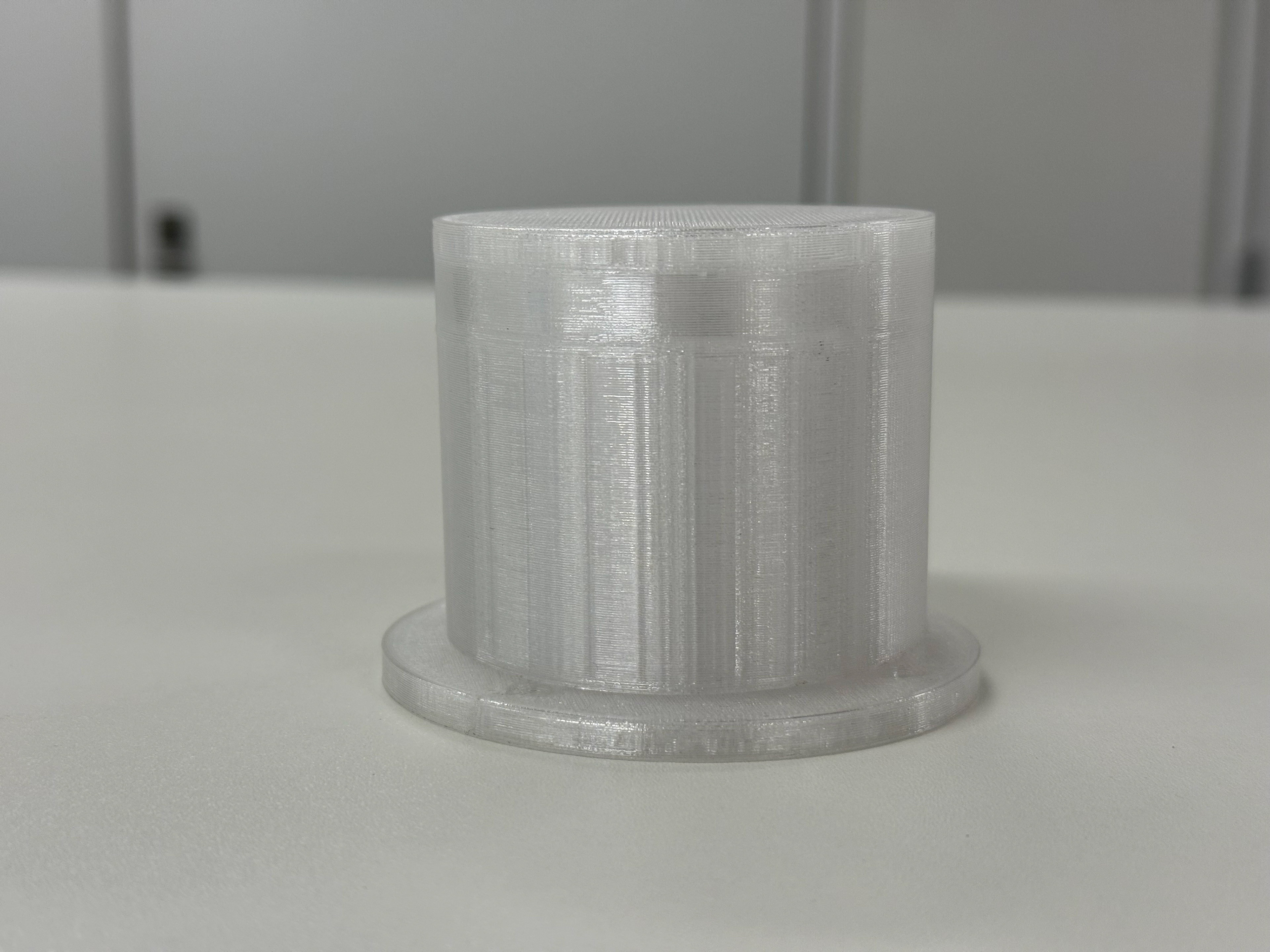

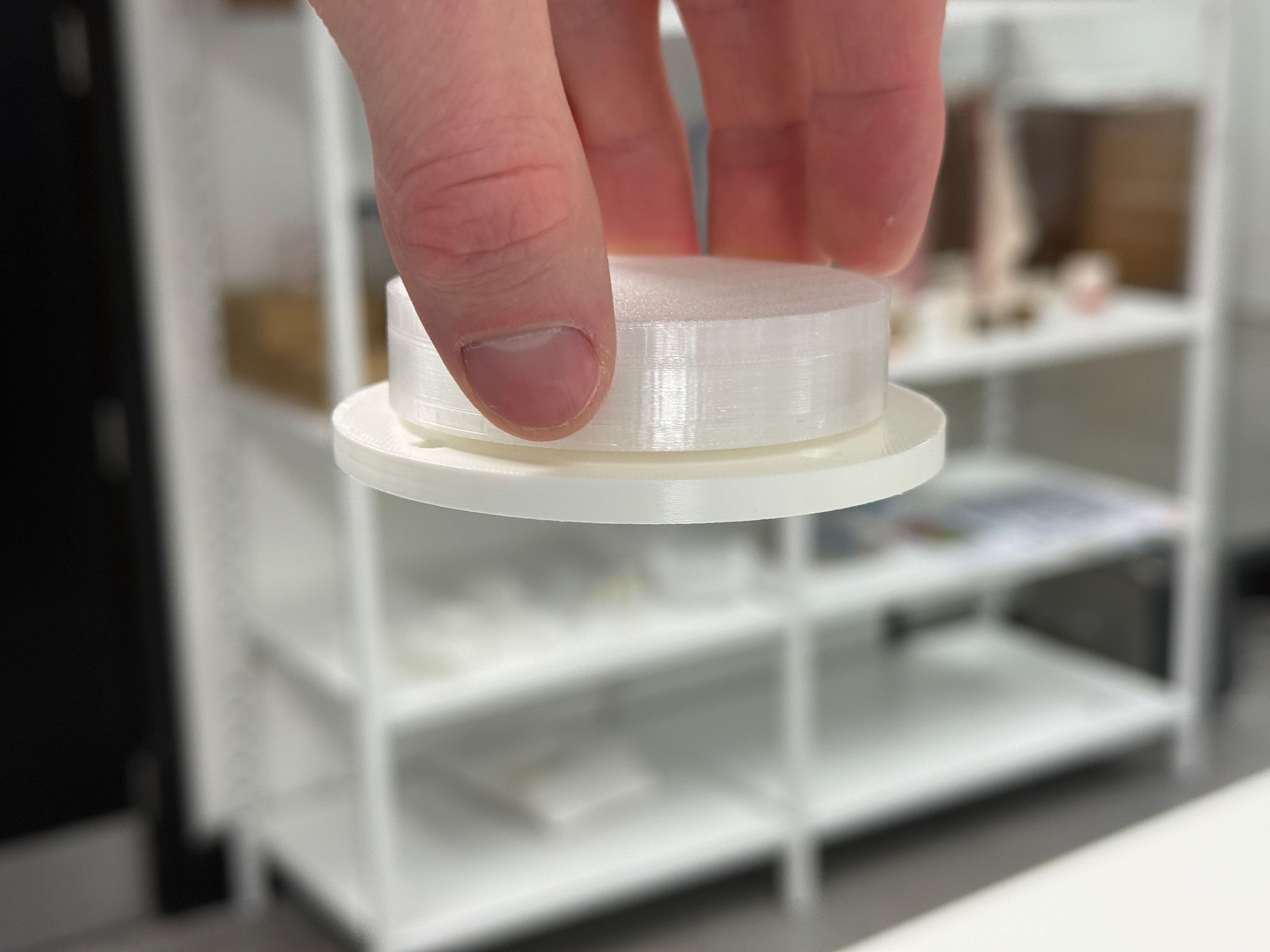

The two separate pieces

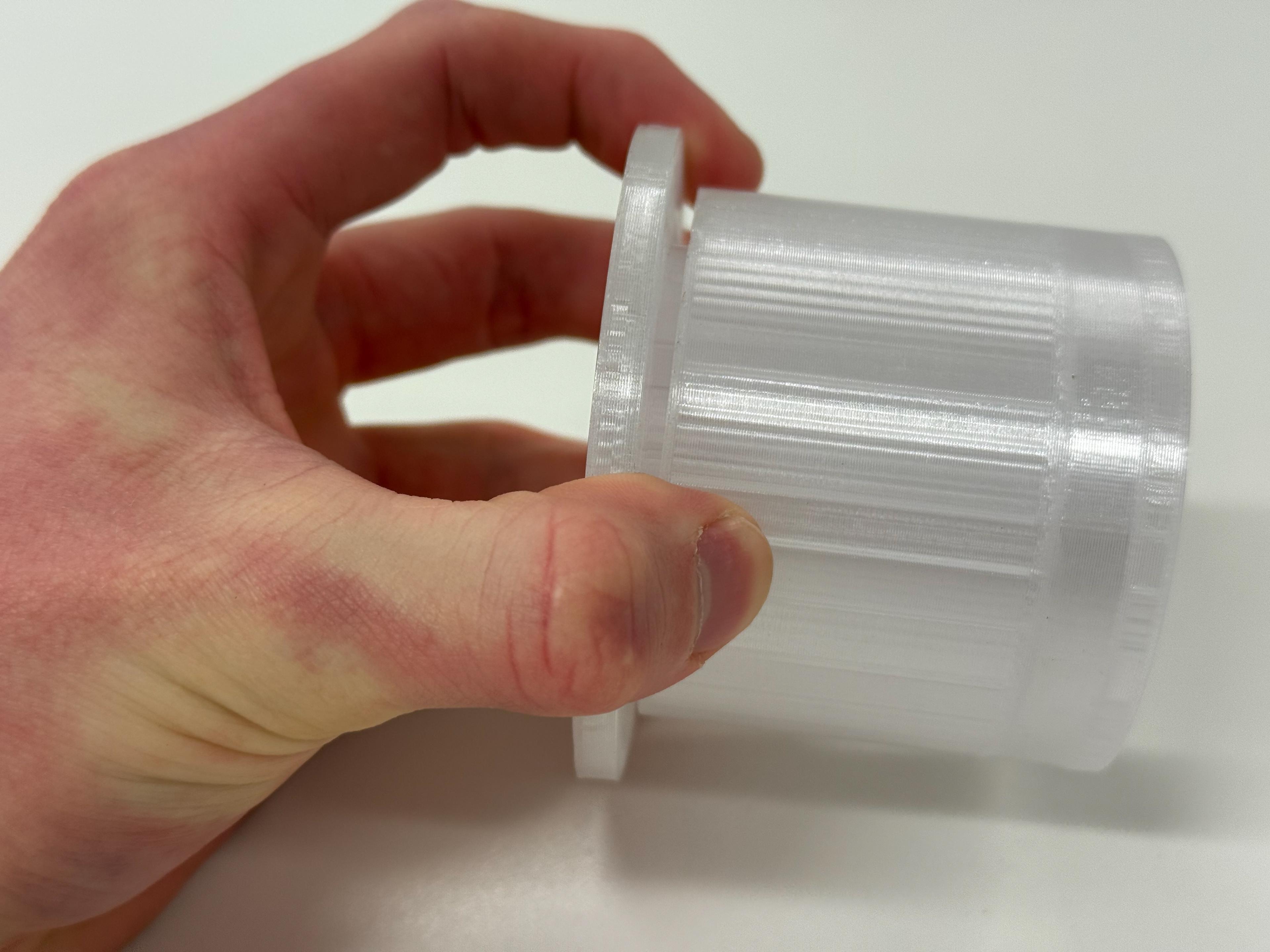

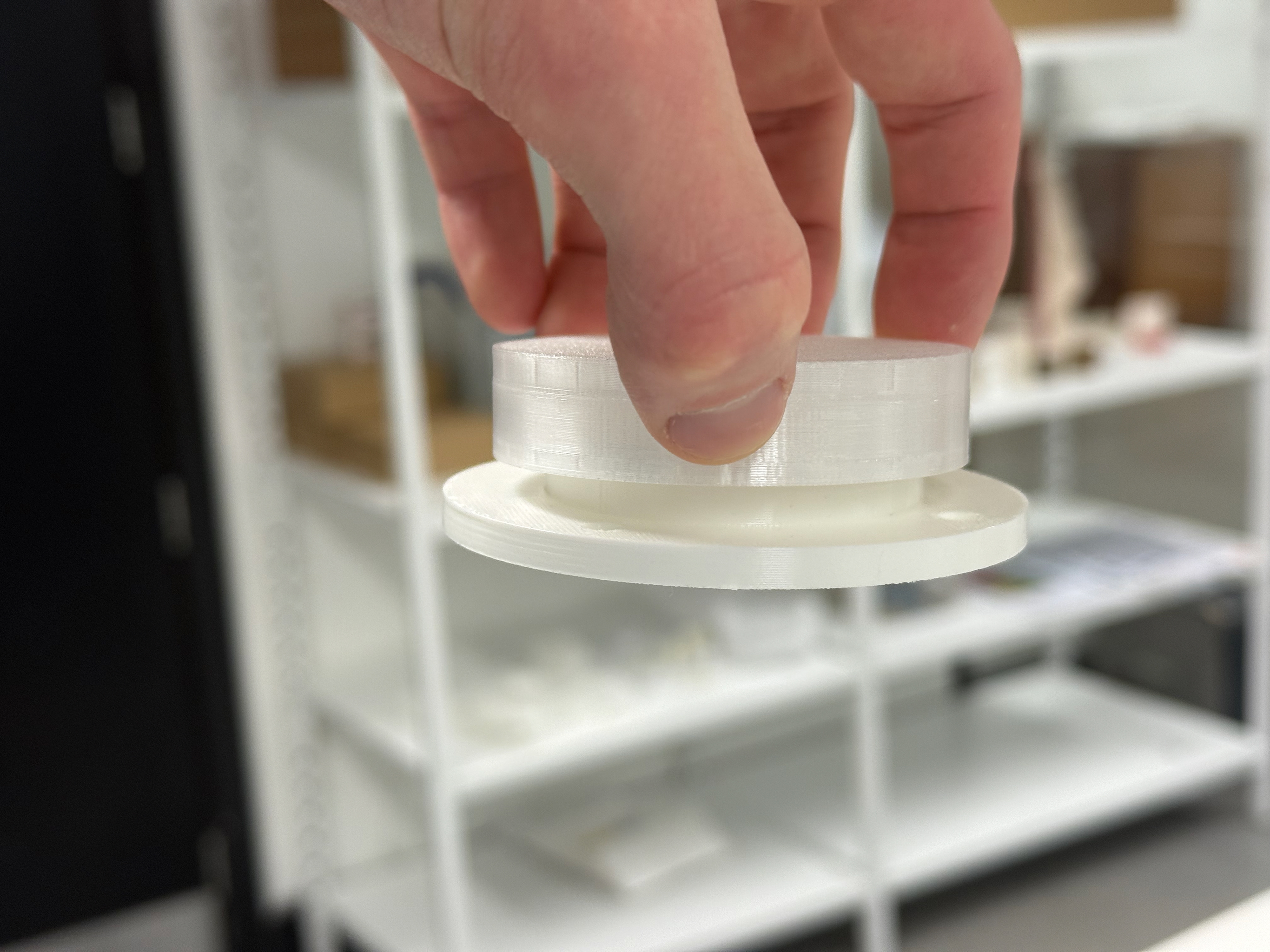

The combined piece

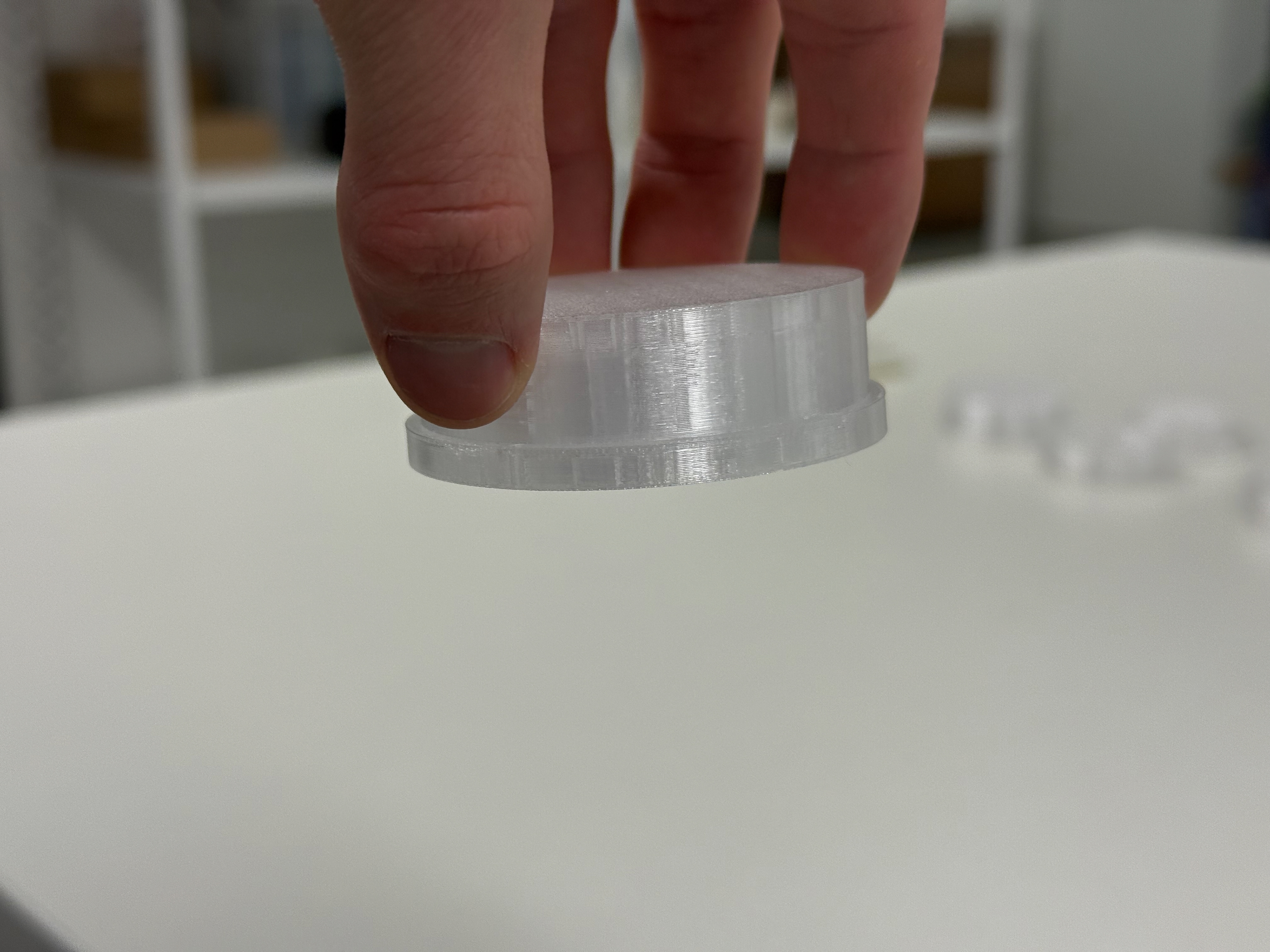

The gap between for the object to go into

Inside fit

How well it holds the object

Slightly too large diameter which caused it to break my object

PETG top part and the 20% infill base

Holds together well

Very hard to move the tabs inwards

The 10% infill base

Doesn't hold together quite as well

Still very hard to move the tabs inwards

Cura layout for both prints

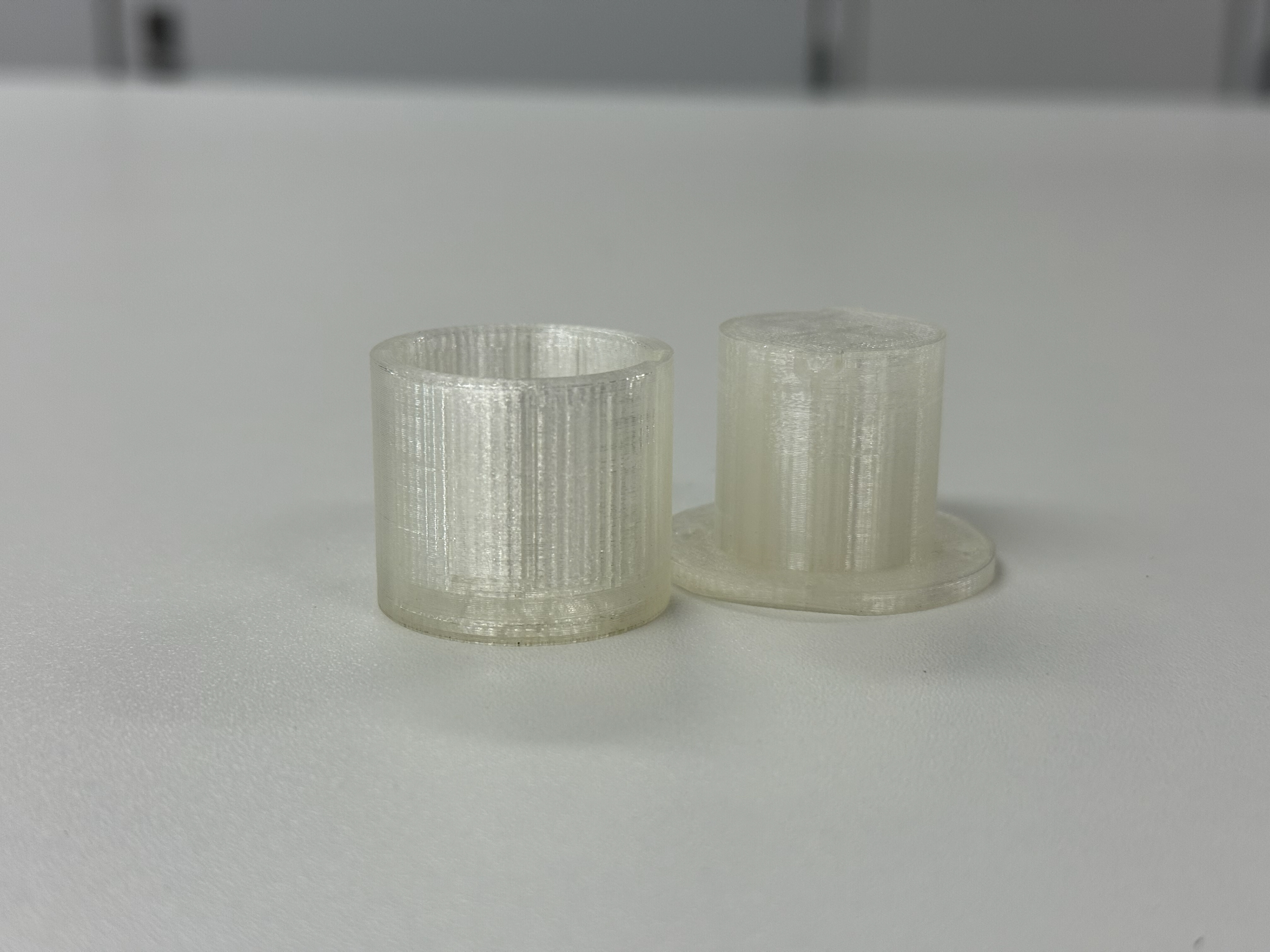

Version 9 two pieces

Holds well but with just a bit of force they come apart very easily

Version 10 two pieces